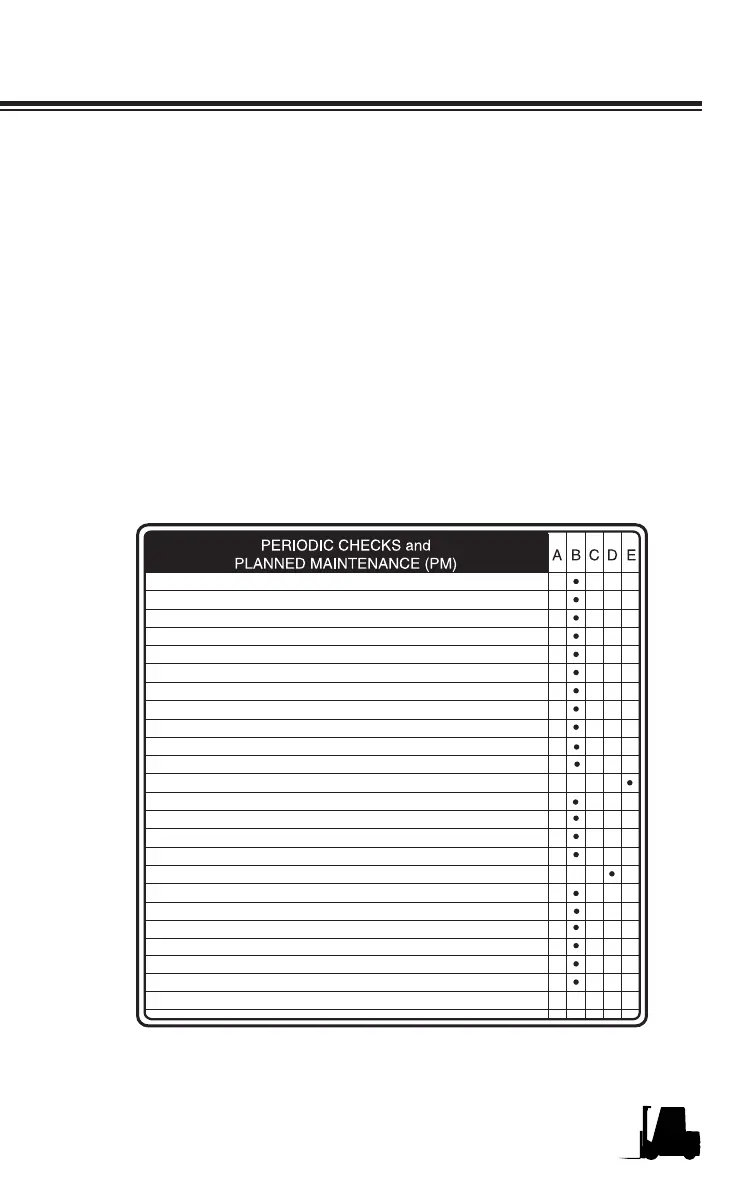

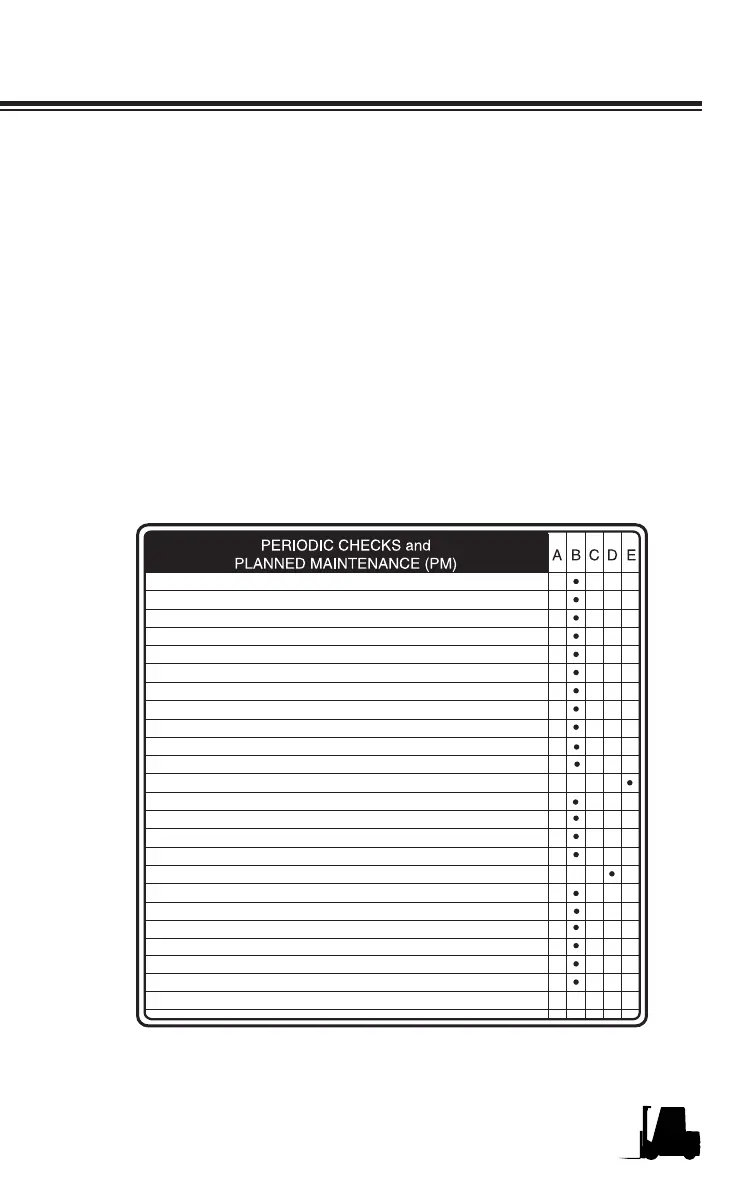

Section 6. Planned Maintenance

6.9

Periodic Maintenance Checks

Check truck visually and inspect components.

Test drive truck/check functional performance.

Air clean truck. (including electrical panel heat sinks)

Check torque on critical fasteners.

Lubricate truck. (See component illustration)

Clean / Check battery terminals, electrolyte level.

Check battery cables / truck receptacle.

Perform battery load test.

Test for shorts and grounds.

Clean drive axle air vent.

Check drive axle fluid level.

Drain and replace drive axle fluid.

Check brake condition and wear.

Check drive axle mounting and fasteners.

Lubricate steer shaft.

Check / Lubricate steer axle wheel bearings.

Replace hydraulic sump fluid and filter.

Clean / Replace hydraulic sump breather.

Lubricate tilt cylinder rod ends.

Lubricate upright and fittings

Check lift chain adjustment and wear.

Check / Lubricate lift chains.

Lubricate upright rollers.

718053

Normal Operation: Basically, eight-hour material handling, mostly in

buildings or in clean, open air on clean paved surfaces.

Severe Operation: Prolonged operating hours or constant usage.

Extreme Operation:

• In sandy or dusty locations, such as: cement plants, lumber mills,

and coal dust or stone crushing sites

• High-temperature locations, such as: steel mills, foundries, etc.

• Sudden temperature changes, such as: constant trips from build-

ings into the open air, refrigeration plants, etc..

If your fork lift truck is used in severe or extreme operating conditions,

you must shorten the maintenance intervals accordingly.

NOTICE

Since the operating environment of lift trucks varies widely,

the above descriptions are highly generalized and should

be applied as actual conditions dictate.

Loading...

Loading...