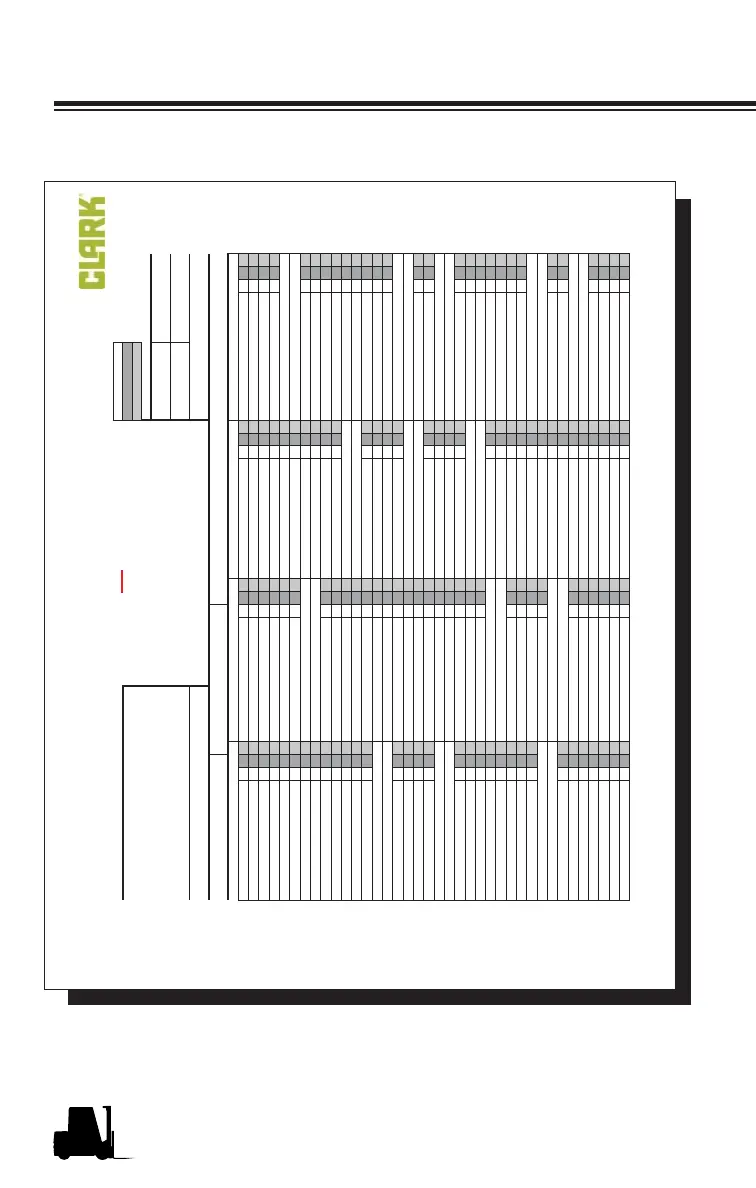

6.10

PM Report Form

PM Report Form

CODE

OK

OK

Potential

x Adjust (Not PM)

Urgent

r Repair or Replace

s Reqs Shop Repair

Date Hour Meter

Date Last PM HRS. Last PM

CUST PO. NO.

SPECIAL INSTRUCTIONS

ega

k

a

e

L

r

o

f

k

c

ehC

.

aeg

a

k

a

e

L

r

ofk

c

e

hC.

a

n

oi

ti

dn

o

Cr

o

toMe

v

irD

.a

esioNnia

rT

evi

r

D

.

a

noitidnoCdoRrednilyC

.bleveLdiulFriovreseRekarB.bnoitidnoCrotoMpmuP.bnoitarepOgnireetS.b

c. Service Brake Operation c. Clean Vent Cap c. Mounting Security / Torque

d. Speed Control d. Pedal Free Travel d. Tilt Cylinder Adjustment (Racking)

Creep Speed e. Pedal Drift

e. Plugging & Directional Control

f. Master Cylinder Mounting

f. Return to Neutral g. Service Brake Wear / Adjustment a. Security of Mounting

g. Hydraulic System Operation h. Park Brake Wear / Adjustment b. Roller Condition / Clearance

h. Pedal Pads & Linkage a. Ground Test i. Brake Line Cable Condition c. Chain & Anchor Condition

i. Parking Brake Operation b. Cable & Terminal Condition j. Brake Linkage Check & Lubricate d. Chain Adjustment

j. Seat Switch (Brake) Operation c. Wire Harness Condition e. Latch and Stop Condition

k. Pedestrian Warning Devices d. Accelerator Test f. Cylinder Condition

(if equipped) e. Contactor Assemblies a. Security of Mounting g. Forks, Locks, Stops

f. Contactor Tip Condition b. Axle Stop Adjustment h. Rail Condition

g. Service Brake Switch Operation c. Drag Link Adjustment i. Trunion Ring Condition

a. Air Clean Truck

h. Parking Brake Switch Operation

d. Check Wheel Bearings

b. Air Clean Electrical Controls i. Seat Switch Operation

c. Air Clean All Motors j. S.R.O. a. Condition

d. Lubricate Truck k. P.M.T. a. Check for Leakage b. Security of Mounting

l. Speed Limit Switches b. Oil Level - Condition

m. Steering Transducer c. Security of Mounting

a. Cable Condition n. Hydraulic Valve Switches d. Tilt Column Operation a. Decals - Missing / Condition

b. Electrolyte Level o. Lift Valve Transducer

b. Data Plate Condition

c. Battery Load Test c. Seat Mounting & Operation

d. Battery Retention Stops a. Check for Leakage d. Seat Belts Condition

e. Specic Gravity

b. Fluid Level - Condition

e. Door & Deck Latches

f. Receptacle Condition

*a. Dierential Fluid Level

c. Clean / Replace Breather f. CTW Mounting Bolts

g. Battery Connector Condition b. Clean Air Vent

*d. Replace Filter

g. Slip Resistance Surfaces

h. Battery Disconnect Condition c. Security of Mounting e. Linkage Adjustment

d. Check Wheel Bearings f. Hose Condition

g. Lift Speed (In./Sec) a. Condition

a. Hour Meter No Load b. Security of Mounting

b. Gauges - All Operate a. Tighten Mounting Bolts Full Load

c. Lights - All Operate b. Tire Condition h. Drift Teas (In./Sec)

d. Wiring Condition c. Drive Lift Cylinder a. Mounting Bolts

e. Horn d. Steer Tilt Cylinder b. Leakage

f. Lift Interrupt e. Tire Pressure c. Operation

g. Operation of Accessories

59-760-0??? February 2007 * See Maintenance Interval in Service Manual

ELECTRIC AC

TRUCK PLANNED

MAINTENANCE REPORT

Comments:

AUTHORIZED SIGNATURE

MODEL & SERIAL NO.

CUSTOMER

23 WHEELS & TIRES

34 UPRIGHT - CARRIAGE

34 LOAD BACK REST

38 SHEET METAL & CTW

32 TILT CYLINDERS

INSPECTOR

26 Steer Axle

A. TEST DRIVE MACHINE 16 MOTORS 23 BRAKE SYSTEM

29 HYDRAULIC SYSTEM

26 STEERING SYSTEM

01 CLEANING & LUBRICATION

13 GAUGES - LIGHTS - INDICATORS

19 ELECTRICAL TESTS

20 DRIVE AXLE

12 BATTERY AND CABLES

39 OVERHEAD GUARD

53 ATTACHMENTS

Loading...

Loading...