Waterside Care

2-6

750-392

CBEX-DE

2. Partial or total old system is involved.

3. Conditions may prevent adequate cleaning of piping.

The pressure vessel waterside should be inspected on a periodic basis. An inspection will reveal true internal

conditions and serve as a check against conditions indicated by chemical analysis of the boiler water. Inspection

should be made three months after initial starting and at regular 6-, 9-, or 12-month intervals thereafter. The fre-

quency of further periodic inspections will depend upon the internal conditions found.

If any unwanted conditions are observed, contact your local Cleaver-Brooks authorized representative for recom-

mendations.

Any sludge, mud, or sediment found will need to be flushed out. If excessive mud or sludge is noticed during

blowdown, the scheduling or frequency of blowdown may need to be revised. The need for periodic draining or

washout will also be indicated.

Any oil or grease present on the heating surfaces should be removed promptly by a boil-out using an alkaline

detergent solution.

2.5 — Boil-Out of a New Unit

The internal surfaces of a newly installed boiler may have oil, grease or other protective coatings used in manu-

facturing. Such coatings must be removed because they lower the heat transfer rate and could cause overheating

of a tube. Before boiling out procedures may begin, the burner should be ready for firing. The operator must be

familiar with the procedure outlined under burner operation.

A general procedure for cleaning a boiler is:

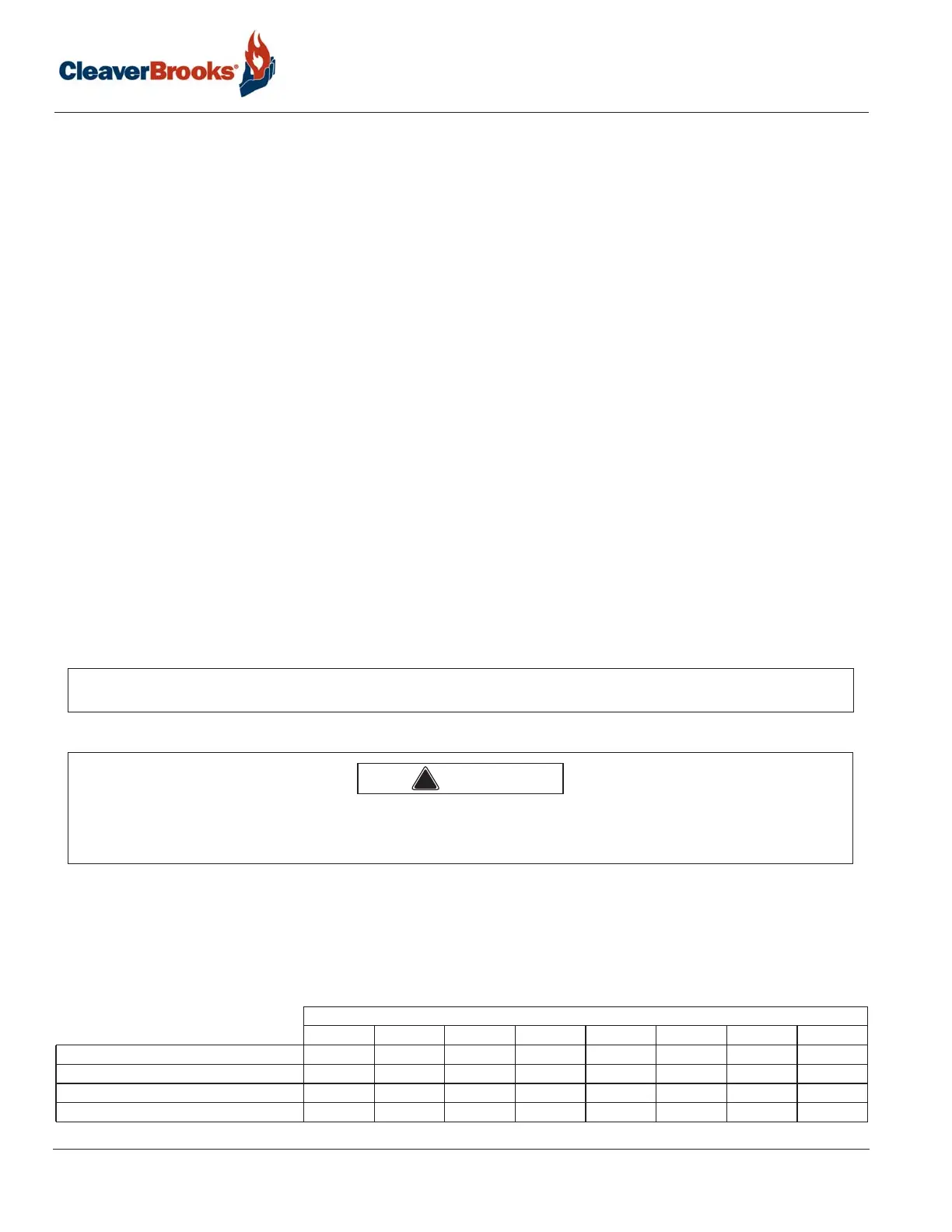

1. Refer to the table below to determine water capacity. Have sufficient cleaning material on hand to complete

the job.

NOTE: Temperature of initial fill of water for hydrostatic tests, boil-out, or for normal operation should be as stated in

the ASME Boiler Code.

Use of a suitable face mask, goggles, rubber gloves, and protective garments is strongly recommended when han-

dling or mixing caustic chemicals. Do not permit the dry material or the concentrated solution to come in contact

with skin or clothing. Failure to follow these instructions could result in serious injury or death.

TABLE 2-2. Water Capacity and Weights

Boiler HP

250 300 350 400 500 600 700 800

Water Volume - Operating, Gal. 1126 1190 1199 2032 1725 1968 1767 1837

Water Volume - Flooded, Gal. 1589 1680 1718 2618 2515 2869 2630 2733

Water Weight - Operating, lbs. 9378 9915 9991 16926 14366 16393 14723 15300

Water Weight - Flooded, lbs. 13240 13996 14315 21805 20952 23899 21909 22765

!

Warning

Loading...

Loading...