Preparations for Startup

3-20

750-392

CBEX-DE

3.12 — High Gas Pressure Switch

Adjust the scale setting to slightly above the normal burning pressure. The control circuit will be broken when

pressure exceeds the normal operating pressure. Unnecessary shutdowns may result if the setting is too close to

normal, however, regulations require that the setting may not be greater than 150% of rated pressure.

Manual resetting is necessary after a pressure rise. Press the reset lever after pressure falls.

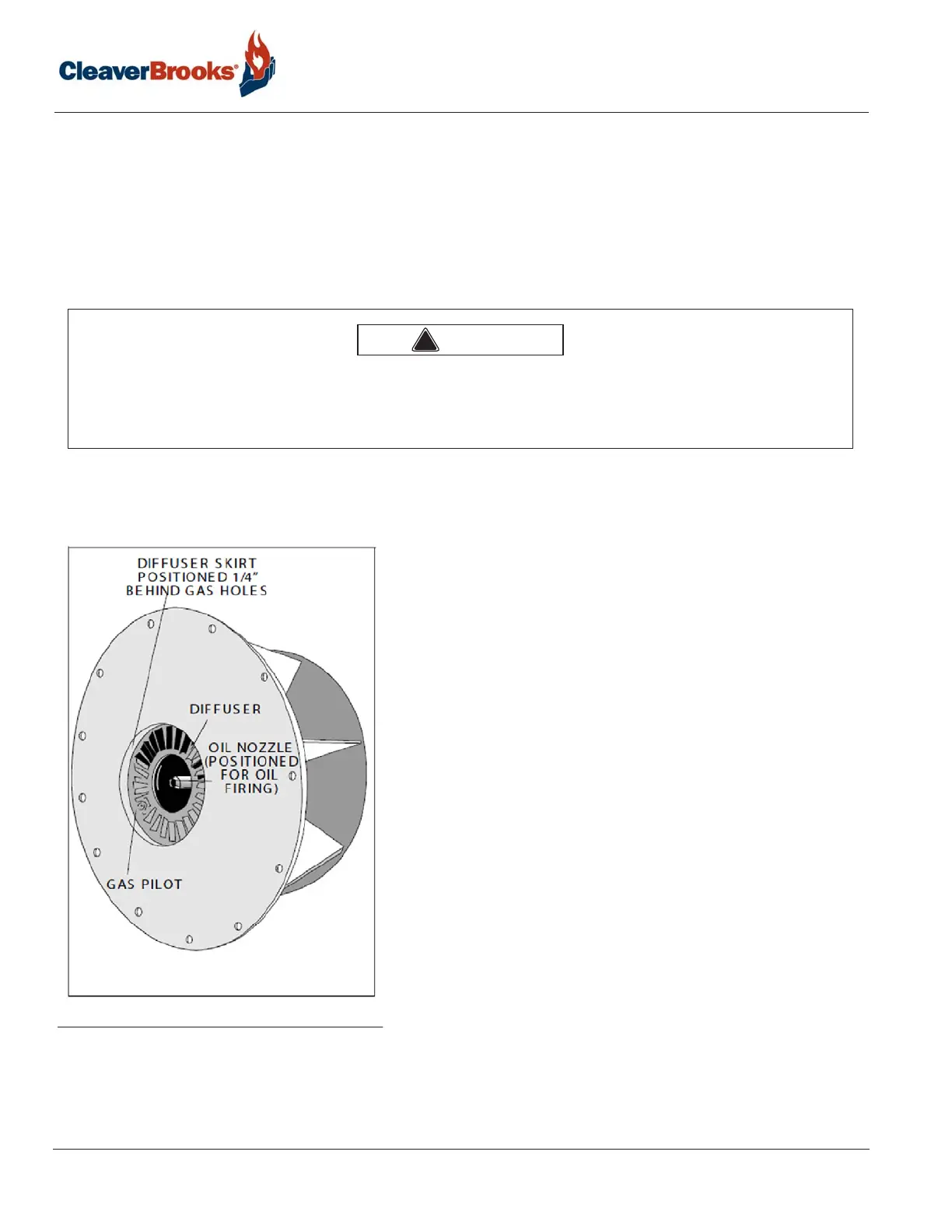

3.13 — Burner Drawer Adjustment

There are relatively few adjustments that can be made to the

burner, however, a check should be made to assure that all com-

ponents are properly located, and that all holding screws are

properly tightened.

The diffuser location on gas fired boilers is important. There

should be 1/4” distance between the edges of the diffuser fins

and gas outlet tubes (spuds) coming from the burner housing.

The setting of an oil fired burner is less exacting and the diffuser

should be located with the diffuser skirt approximately 1-1/8” in

front of the oil nozzle.

When the proper diffuser location is ascertained, the setting of

the nozzle in relation to the diffuser should be checked. This

generally is set at time of manufacture and seldom needs alter-

ing. It is most important that oil spray does not impinge upon

the diffuser. The distance that the nozzle is behind the diffuser

has some latitude, and individual installation may require a

slight deviation.

It is advisable to check for tight shutoff of fuel valves. Despite precautions and strainers, foreign material in either

new or renovated fuel lines may lodge under a valve seat and prevent tight closure. The situation is especially true in

new installations. Promptly correct any conditions causing leakage. Failure to follow these instructions could result in

serious injury or death.

!

Warning

FIGURE 3-7. Burner drawer adjustments

Loading...

Loading...