750-392

CBEX-DE

5-21

Refractory

Keep the motor and other components free from dust and dirt to prevent overheating and damage. Motor lubrica-

tion should follow manufacturer’s recommendations.

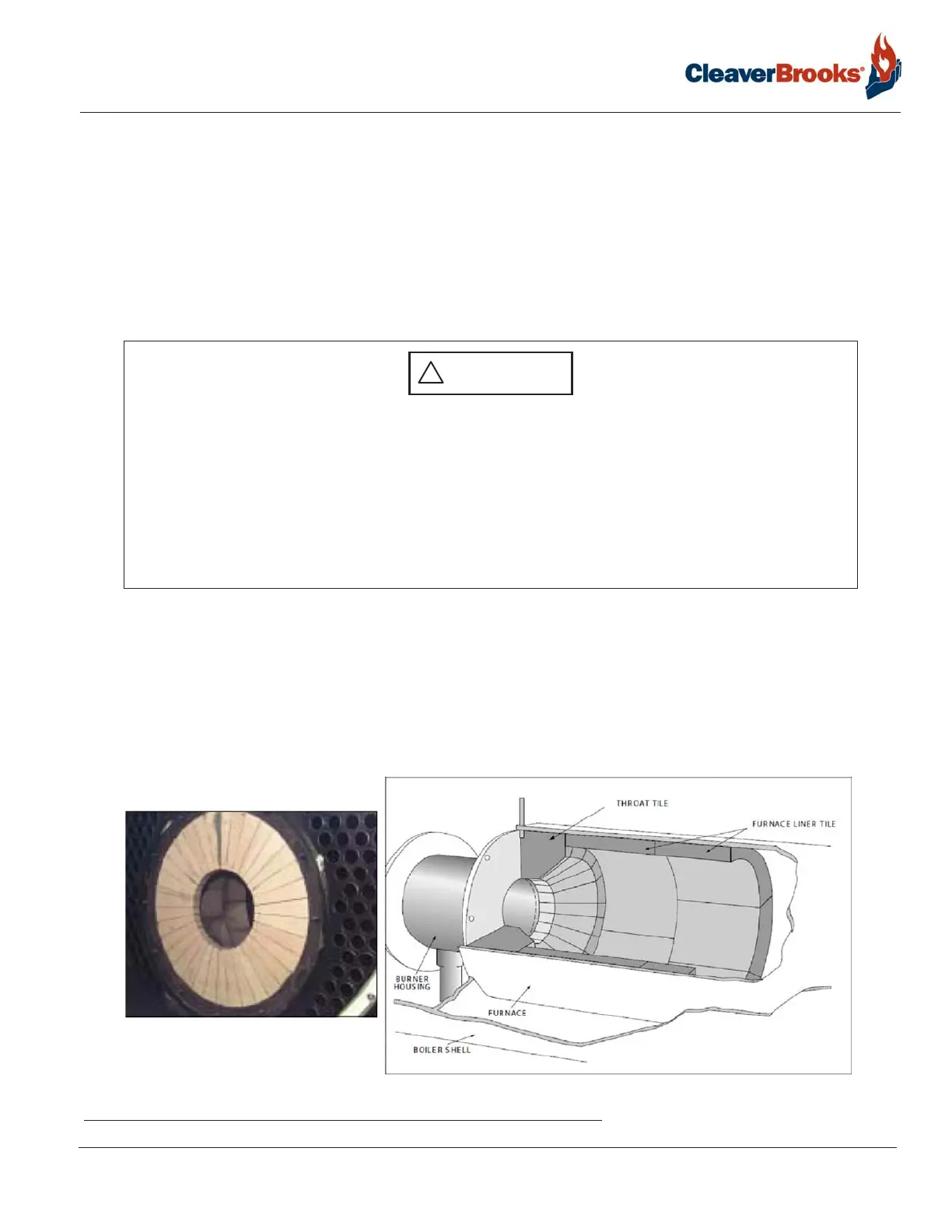

5.19 — Refractory

The boiler is shipped with completely installed refractory. This consists of furnace throat tile, furnace liner, and

the crawl-way plug. Normal maintenance requires little time and expense, and prolongs the operating life of the

refractory.

Preventive maintenance through periodic inspection will keep the operator informed of the condition of the refrac-

tory, and will guard against unexpected and unwanted downtime and major repairs.

Frequent wash coating of the refractory surfaces is recommended. High-temperature bonding, air-dry type mor-

tar, diluted with water to the consistency of light cream, is used for wash coating. Re-coating intervals will vary

with operating loads and are best determined by the operator when the boiler is opened for inspection.

FIGURE 5-14. Throat Tile and Furnace Liner

When doing refractory service or repair work, observe the following precautions:

• Ensure the area is well ventilated.

• Wear a respirator approved by the National Institute for Occupational Safety and Health (NIOSH).

• Wear gloves, eye protection, and long-sleeved, loose-fitting clothing.

Dispose of refractory waste material in an airtight plastic bag.

Vacuum clothing before leaving the work site. Wash work clothes separately from other laundry.

Wash all exposed body areas with soap and water.

!

WARNING

Loading...

Loading...