Inspection and Maintenance

5-4

750-392

CBEX-DE

Remove the pipe plugs from the tees or crosses and make certain the cross-connecting piping is clean and free of

obstructions. Controls must be mounted in a plumb position for proper performance. Determine that piping is

vertically aligned after shipment and installation and throughout life of equipment.

Frequent “Float Check Fail” or “Slow Float” warnings may indicate a sludge buildup in the sensor well. Remove

the probe assembly and clean the sensor well.

A blowdown of the water controls on a steam boiler should be performed daily.

5.3.2 — Hot Water Boiler

It is impractical to blow down the low-water cutoff devices on a hot water boiler since the entire boiler and sys-

tem are flooded. Many hot water systems are fully closed and any loss of water will require make-up and addi-

tional feedwater treatment that might not otherwise be necessary. Since the boiler and system arrangement

usually make it impractical to perform daily and monthly maintenance of the low-water cutoff devices, it is

essential to verify proper operation. Remove the operating mechanism from the bowl annually or more frequently,

if possible, to check and clean float ball, internal moving parts, and the bowl housing. Also check the cross-con-

necting piping to be certain that it is clean and free of obstruction.

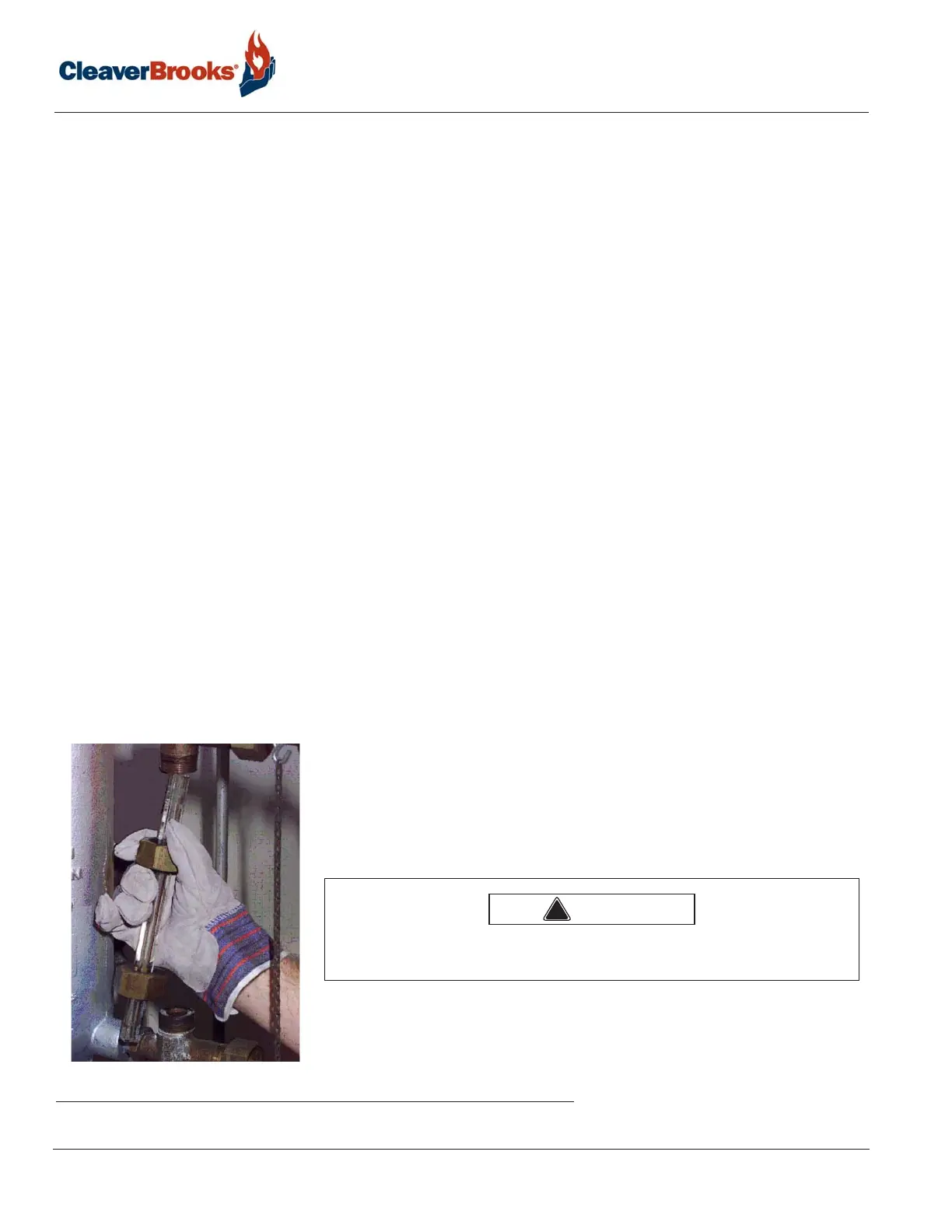

5.4 — Water Gauge Glass

A broken or discolored glass should be replaced at once. Periodic replacement should be a part of the mainte-

nance program. Always use new gaskets when replacing a glass. Use a proper size rubber packing. Do not use

loose packing which could be forced below the glass and possibly plug the valve opening.

Close the gauge glass valves when replacing the glass and open the drain valve to release any pressure. Slip a

packing nut, a packing washer, and packing ring onto each end of the glass. Insert one end of the glass into the

upper gauge valve body far enough to allow the lower end to be dropped into the lower body. Slide the packing

nuts onto each valve and tighten.

It is recommended that the boiler is off and cool when the glass is

replaced.

Check try-cocks and gauge cocks for freedom of operation and clean as

required. It is imperative that the gauge cocks are mounted in exact align-

ment. If they are not, the glass will be strained and may fail prematurely.

FIGURE 5-1. Water Column Gauge Glass Replacement

Do not attempt to change the gauge glass while the boiler is in service.

Failure to follow these instructions could result in serious injury or death.

!

Warning

Loading...

Loading...