Waterside Care

2-10

750-392

CBEX-DE

Equipment generally consists of two quick opening valves and one slow opening valve. The valves and necessary

piping are not normally furnished with the boiler. but supplied by others. All piping must be routed to a safe point

of discharge. Piping must be properly supported and free to expand.

Continuous Blowdown

Continuous blowdown is used in conjunction with a surface blowoff tapping (furnished on units 60” in diameter

and larger) on the top center line of the pressure vessel. It is provided with an internal collecting pipe terminating

slightly below the working water level for the purpose of skimming dissolved solids, oil, or other impurities from

the surface of the pressure vessel water.

A controlled orifice valve or an auto-sensing/metering valve is used to allow a continual, yet controlled flow of

concentrated water to drain or a place of recovery.

The flow control valve and piping are generally provided by others. All piping must be routed to a safe point of

discharge.

2.7.2 — Frequency of Manual Blowdown

When continuous blowdown is utilized, manual blowdown is primarily used to remove suspended solids or

sludge. The continuous blowdown removes sediment and oil from the surface of the water along with a pre-

scribed amount of dissolved solids.

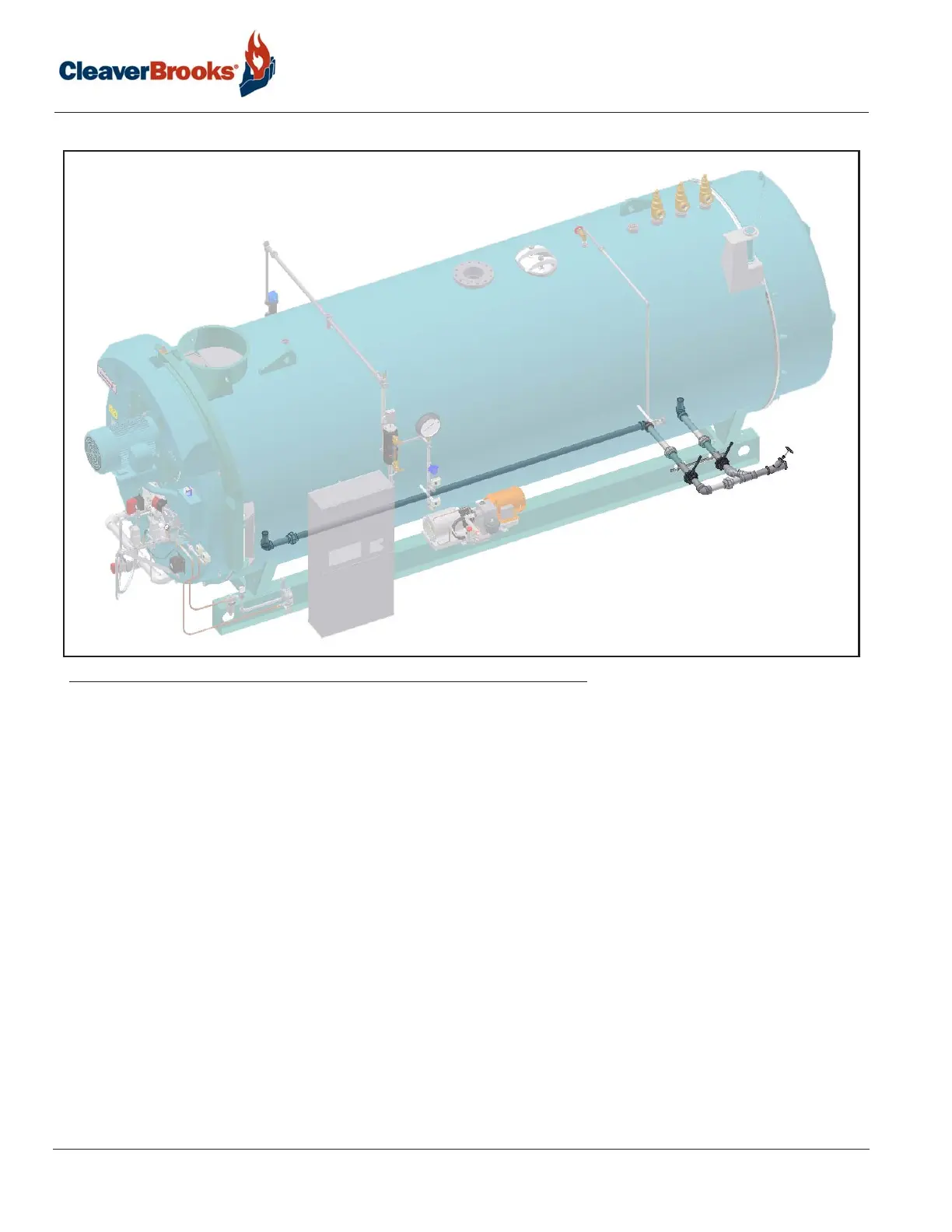

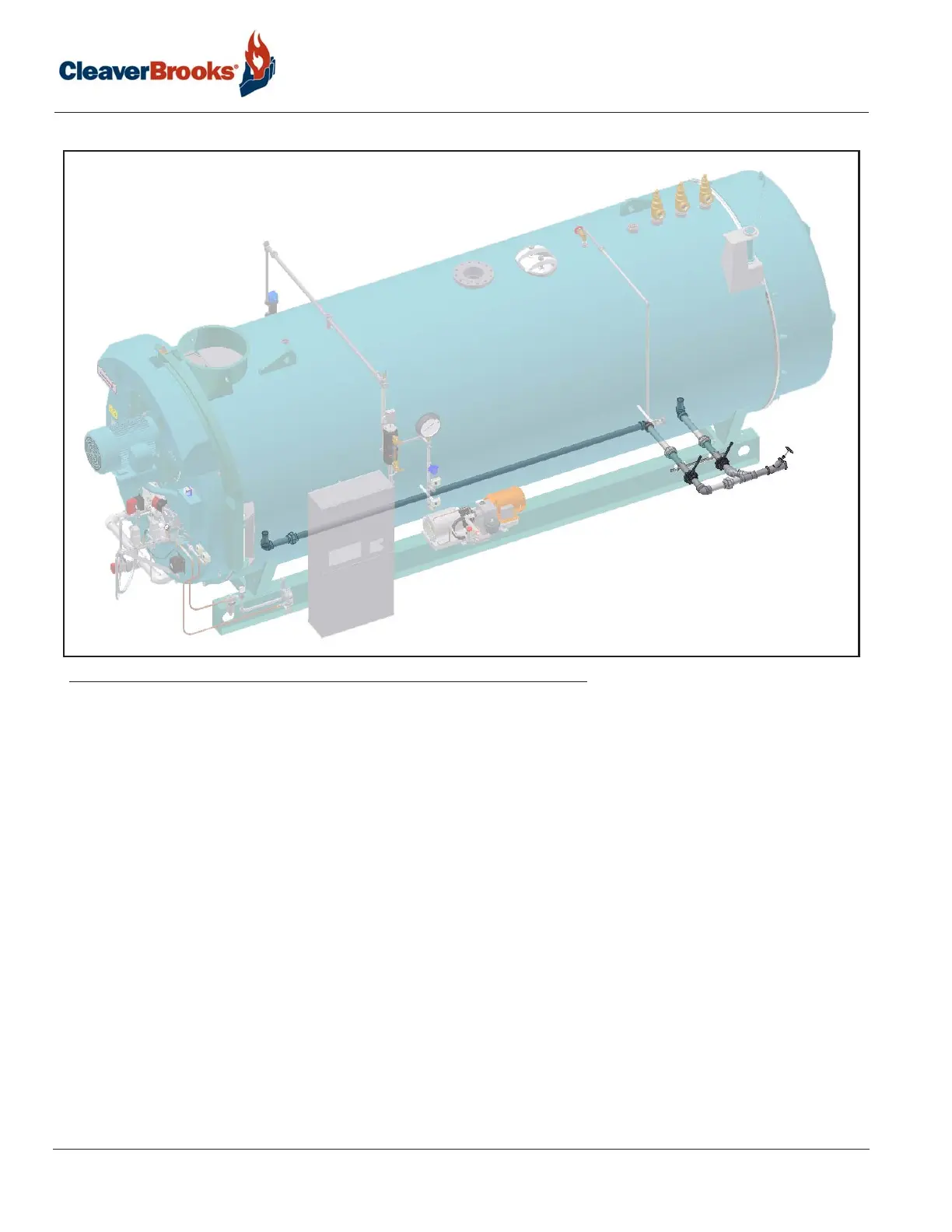

FIGURE 2-2. Bottom blowdown piping

Loading...

Loading...