Inspection and Maintenance

5-16

750-392

CBEX-DE

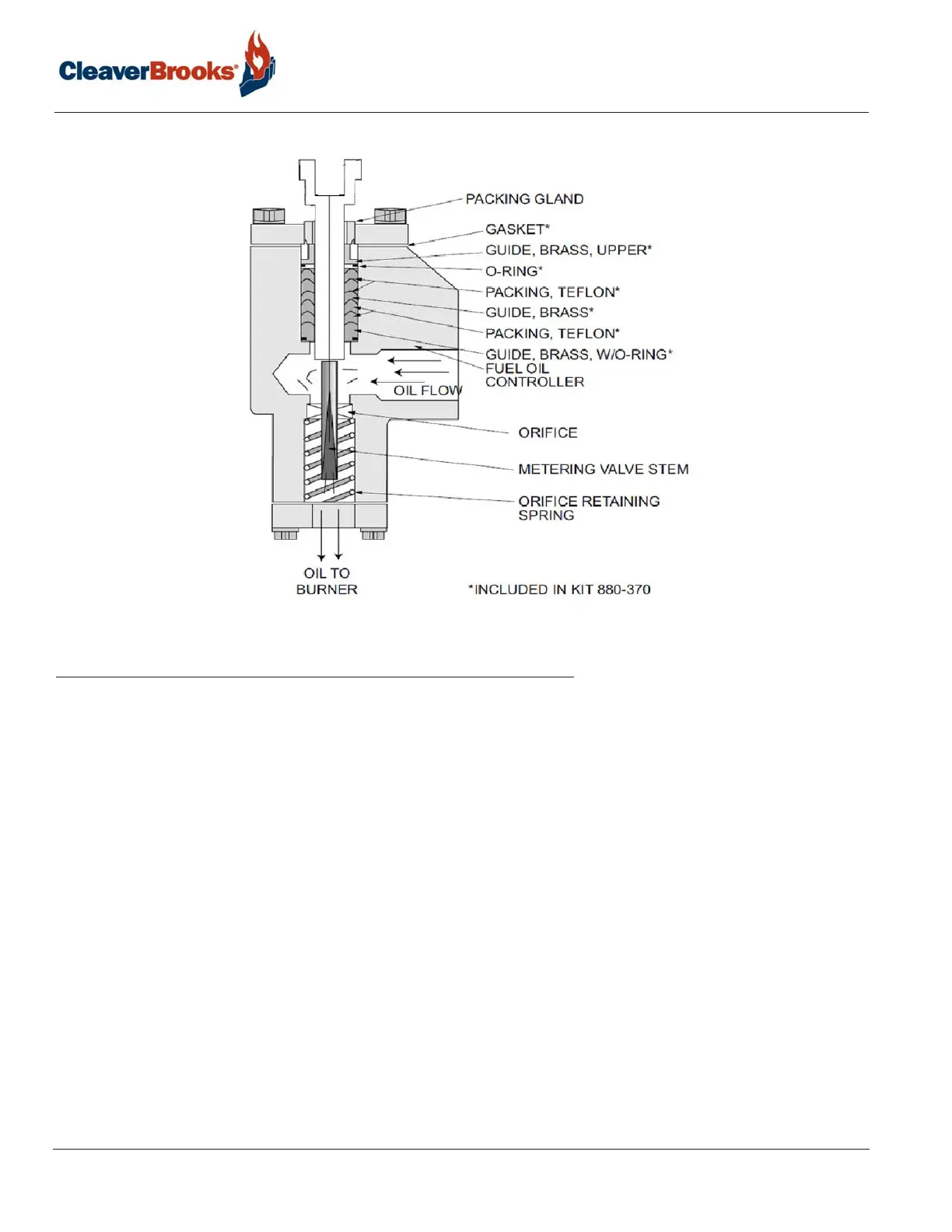

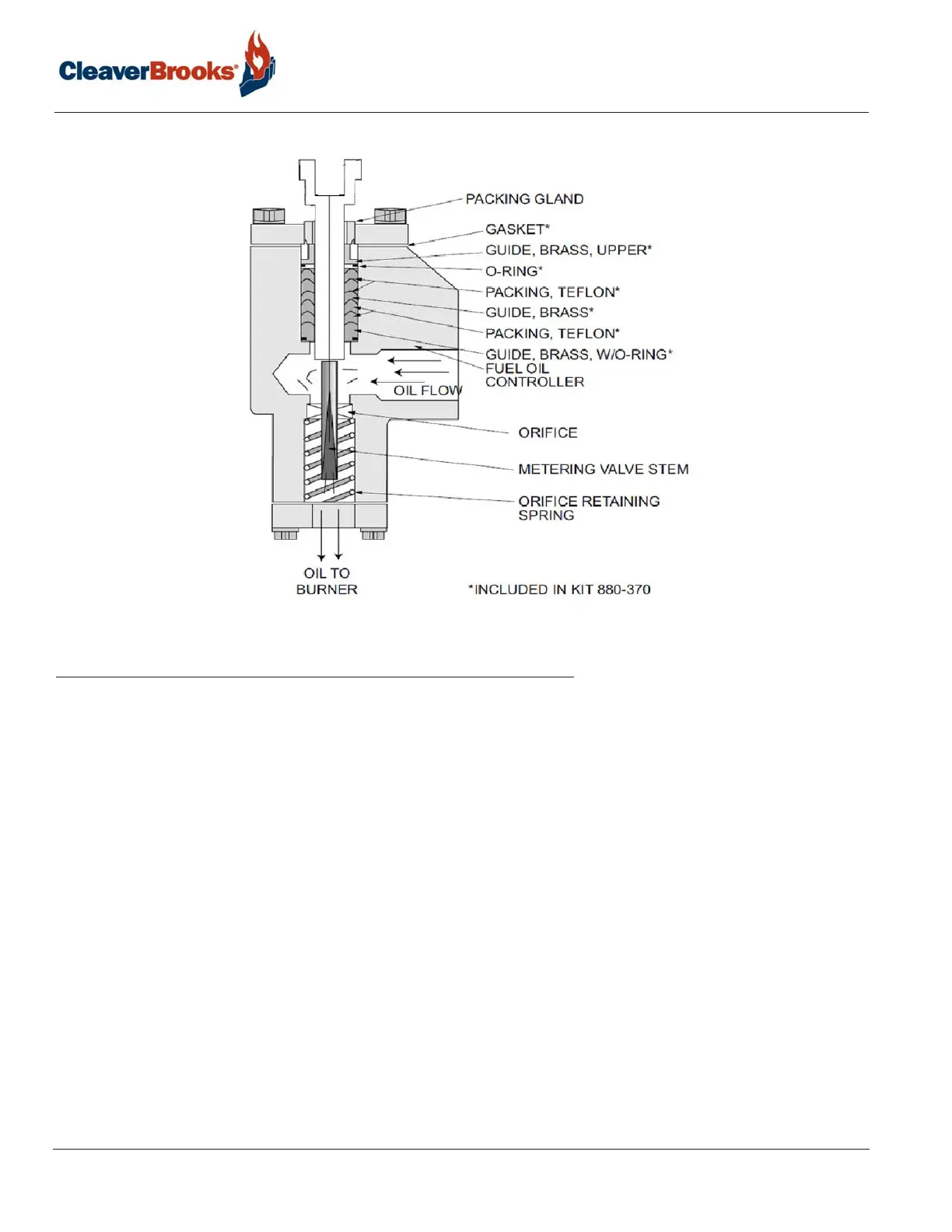

FIGURE 5-10. Fuel Stem Packing, Cross-Section

15. Snug the packing gland, but only sufficiently to place slight tension on the packing. The stem must move

freely from the force of the spring.

16. Work the stem up and down several times to ensure that it moves freely.

17. Depress the valve stem and replace the linkage assembly. SINGLE-POINT SYSTEMS: Depress the valve stem and

replace the cam. Mate the match-marks and secure the setscrews. Be sure the cam spring is centered in the

roller.

18. Restore oil flow. Test fire the burner at various firing rates being certain that the metering stem moves freely.

19. Tighten the packing gland after a period of operation, if necessary, to maintain proper pressure on the pack-

ing. Do not over-tighten.

If there are indications that the oil metering valve has become clogged at its orifice, it will be necessary to disas-

semble the control to remove the obstruction. Clean the slotted stem of the oil metering valve with suitable sol-

vent and blow-dry with dry shop air. Follow the procedure outlined above when removing or re-installing the

metering valve stem. Also check all fuel line strainers.

Should a pressure adjusting or relief valve become clogged, disassemble by releasing the locknut and backing off

the screw to relieve tension on the diaphragm. Remove the valve cover and the diaphragm to expose any dirt or

foreign material which may have entered the valves. Clean out carefully and reassemble. It is recommended that

the diaphragms be replaced annually.

Loading...

Loading...