®

www.climacoolcorp.com

16

Figures 19 and 20 on page 16). The purpose of the chiller/

heater system bypass is to prevent deadheading of the

pumps when all of the internal unit valves go closed as well

modules remaining for that duty. Also, with a module acting

as a bypass increased wear of heat exchangers may be

bypass kits must be installed on each water source loop

and controls are integrated with the CoolLogic software.

Installation location can be found on page 16 – Water Piping

The design piping must accommodate one module’s worth

he eld supplied piped chiller/

heater system bypass must be controlled by others. There

are system communication delays, polling and network

water/evaporator, hot water/condenser water systems.

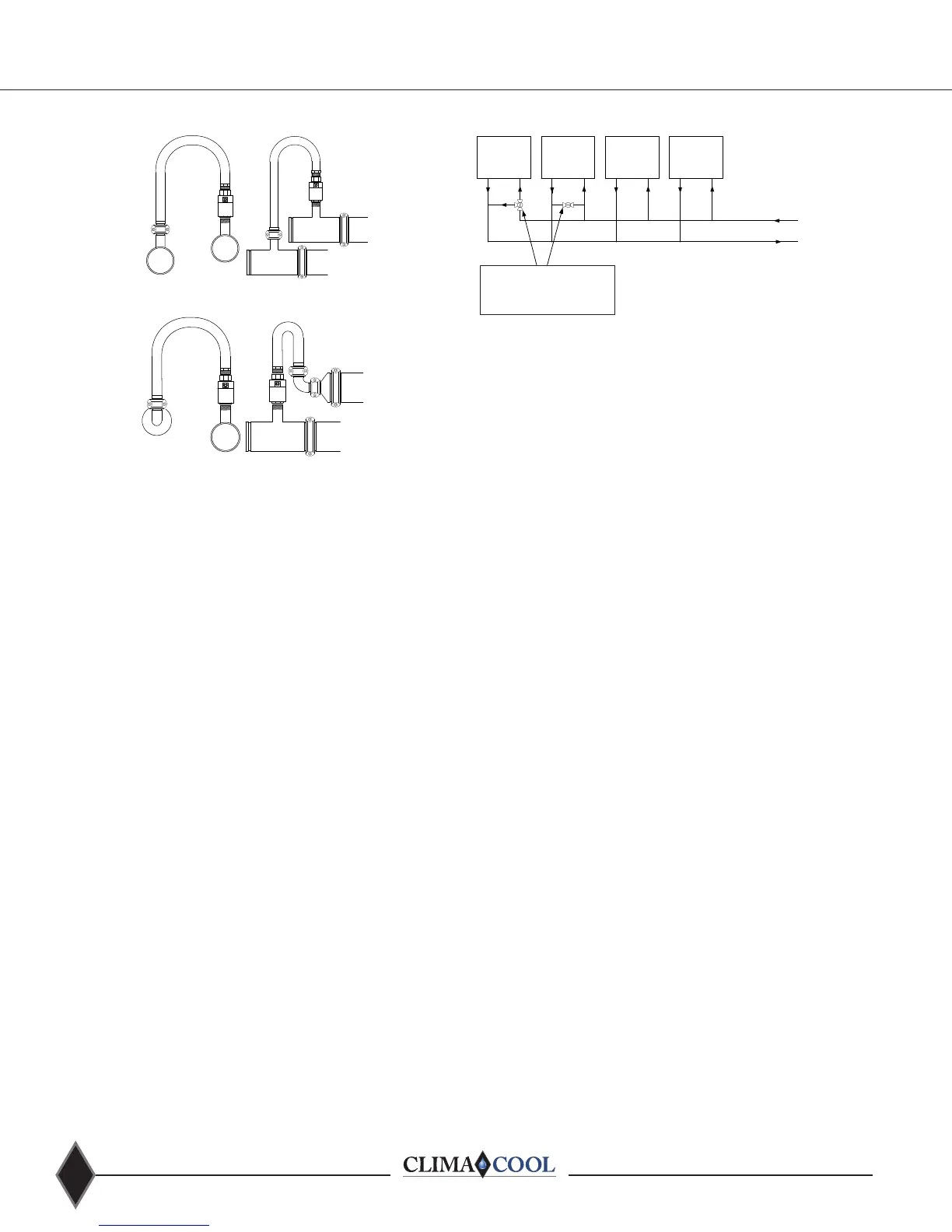

LOAD 1

FROM CHILLER BANK

TYPICAL LOAD BYPASS VALVE ARRANGEMENT

TO CHILLER BANK

LOAD 2 LOAD 3 LOAD X

TYPICAL CHILLED AND HOT WATER

LOAD SIDE BYPASS VALVES

SIZE EQUIVALENT TO ONE MODULE

WORTH OF FLOW

Figure 18 - Typical Load Bypass Valve Arrangement

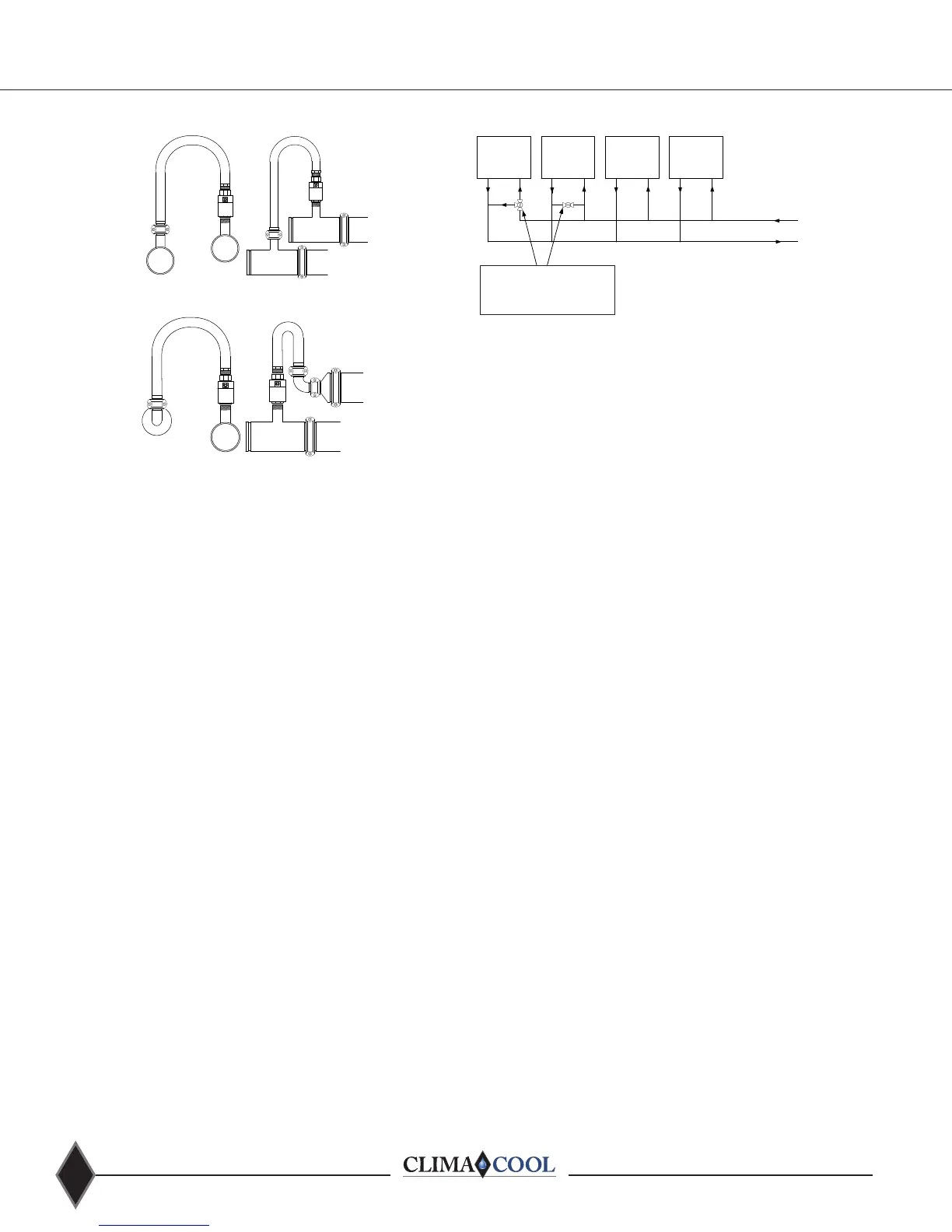

HEADER BYPASS

REVERSE RETURN

No.10

2" 90°

No.50

Reducer

6 x 2

Module

Header

No. 29 Reducing Tee

w/Thd. Branch

6 x 6 x 2

Module

Header

SIDE VIEW

6"

Grooved Coupling

6"

Grooved Coupling

2"

Grooved

Coupling

Hose Kit

2"

Grooved

Coupling

2" Belimo

Ball Valve &

Actuator

No. 29 Reducing Tee

w/Thd. Branch

6 x 6 x 2

END VIEW

No.10

2" 90°

Elbow

No.50 Reducer

6 x 2

Hose Kit

2" Belimo

Ball Valve &

Actuator

2"

Grooved

Coupling

HEADER BYPASS

REVERSE RETURN

No.10

2" 90°

No.50

Reducer

6 x 2

Module

Header

No. 29 Reducing Tee

w/Thd. Branch

6 x 6 x 2

Module

Header

SIDE VIEW

6"

Grooved Coupling

6"

Grooved Coupling

2"

Grooved

Coupling

Hose Kit

2"

Grooved

Coupling

2" Belimo

Ball Valve &

Actuator

No. 29 Reducing Tee

w/Thd. Branch

6 x 6 x 2

END VIEW

No.10

2" 90°

Elbow

No.50 Reducer

6 x 2

Hose Kit

2" Belimo

Ball Valve &

Actuator

2"

Grooved

Coupling

Figure 17 - Reverse Return

No. 25 Grooved Branch

6 x 6 x 2

Module

Header

6"

Grooved Coupling

HEADER BYPASS

DIRECT RETURN &

SIMULTANEOUS HTG & CLG

No. 29 Reducing Tee

w/Thd. Branch

6 x 6 x 2

Module

Header

6"

Grooved Coupling

SIDE VIEW

No. 25 Grooved Branch

6 x 6 x 2

No. 29 Reducing Tee

w/Thd. Branch

6 x 6 x 2

END VIEW

Hose Kit

2" Belimo

Ball Valve &

Actuator

2"

Grooved

Coupling

2" Belimo

Ball Valve &

Actuator

Hose Kit

2"

Grooved

Coupling

No. 25 Grooved Branch

6 x 6 x 2

Module

Header

6"

Grooved Coupling

HEADER BYPASS

DIRECT RETURN &

SIMULTANEOUS HTG & CLG

No. 29 Reducing Tee

w/Thd. Branch

6 x 6 x 2

Module

Header

6"

Grooved Coupling

SIDE VIEW

No. 25 Grooved Branch

6 x 6 x 2

No. 29 Reducing Tee

w/Thd. Branch

6 x 6 x 2

END VIEW

Hose Kit

2" Belimo

Ball Valve &

Actuator

2"

Grooved

Coupling

2" Belimo

Ball Valve &

Actuator

Hose Kit

2"

Grooved

Coupling

Figure 16 - Direct Return

Water Piping

TYPICAL CHILLED AND HOT WATER

LOAD SIDE BYPASS VALVES

SIZE EQUIVALENT TO ONE

MODULE WORTH OF FLOW

Load Side System Bypass (Air Handlers, Fan

Coils, etc.)

A load system bypass is required for preventing pump

Examples of an acceptable load side system bypass are:

• Utilize a quantity of 3-way control valves on the largest

loads farthest from the chiller/heater system.

• Field piping with a control valve to provide a bypass

across the larger system loads when their 2-way valves

go closed.

Please refer to Figure 18 for a typical load bypass

valve arrangement. The load side system bypass should be

sized for an absolute minimum of one module’s worth of

ton are also required to maintain proper system thermal

inertia. This is to avoid short cycling of compressors in the

chiller/heater system as well as prevent nuisance alarms.

Loading...

Loading...