®

www.climacoolcorp.com

50

Basket Strainers

The correct size of Basket Strainer is determined by its job

function, not by the size of the pipeline.

Pre Installation Checklist:

1.

free of defects. The pipeline should also be checked for

proper alignment. Strainers should never be utilized to

realign an existing piping system.

2.

type as the basket strainer being installed. Raised face

3. Ensure that the pipeline setup allows a horizontal

installation of the basket strainer.

4. If pipeline strain is a concern when installing larger

should be used to provide additional support. Larger

reducing strain on the pipeline.

5. If the basket strainer is to be located on the discharge

side of a pump, then a safety release valve must be

installed between the basket strainer and the pump.

Installation Procedure:

1. To provide for easier maintenance, the basket strainer

should be located where the drain plug can be removed

and where there is ample space above the basket

strainer for screen removal.

2. Before placing the basket strainer into place, support

the existing pipeline with pipe supports near the inlet

and outlet connections of the basket strainer.

3. Place the basket strainer into the pipeline ensuring

large or heavy strainers, lift the basket strainer into

place using slings positioned underneath the inlet and

outlet connections.

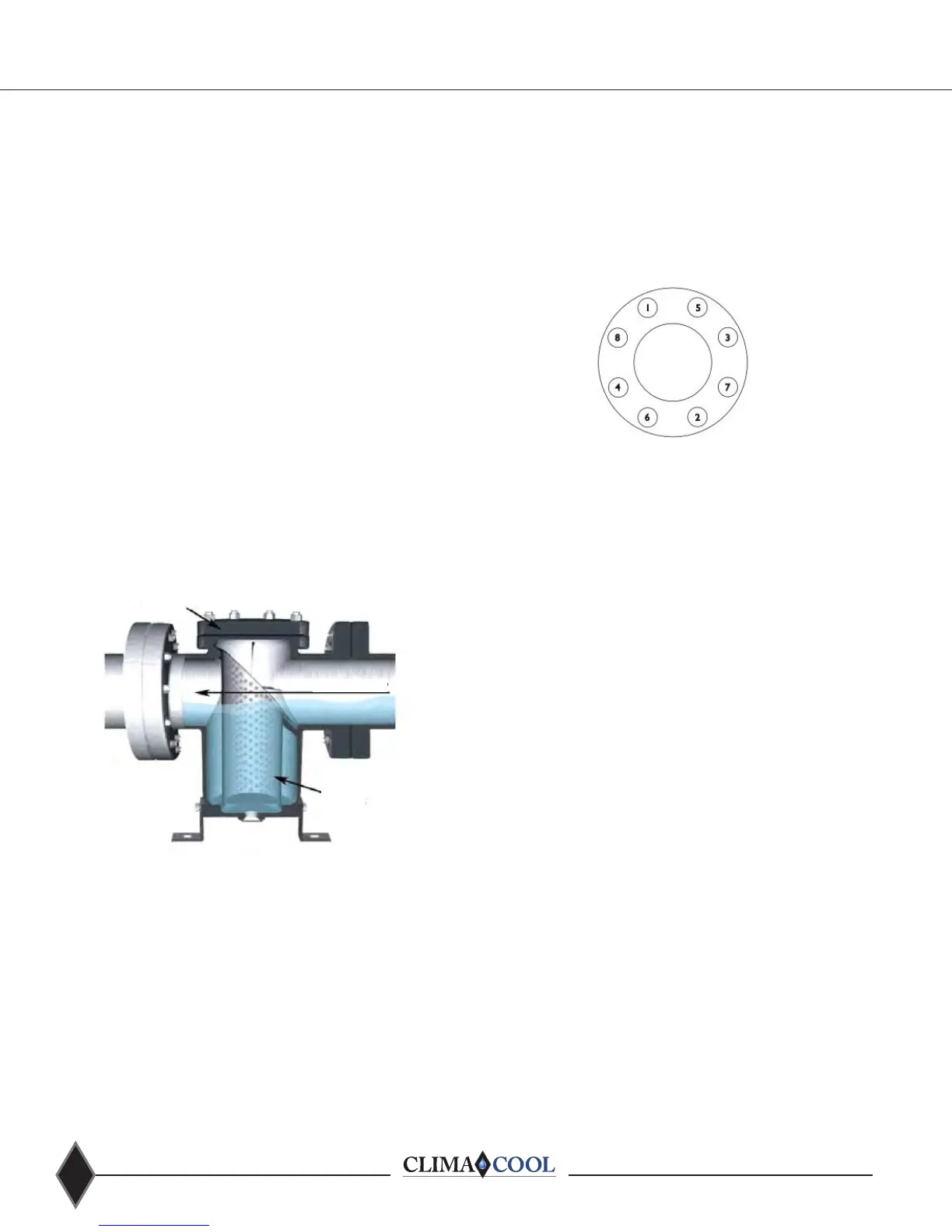

Figure 36 - Installed Basket Strainer with Bolted Cover

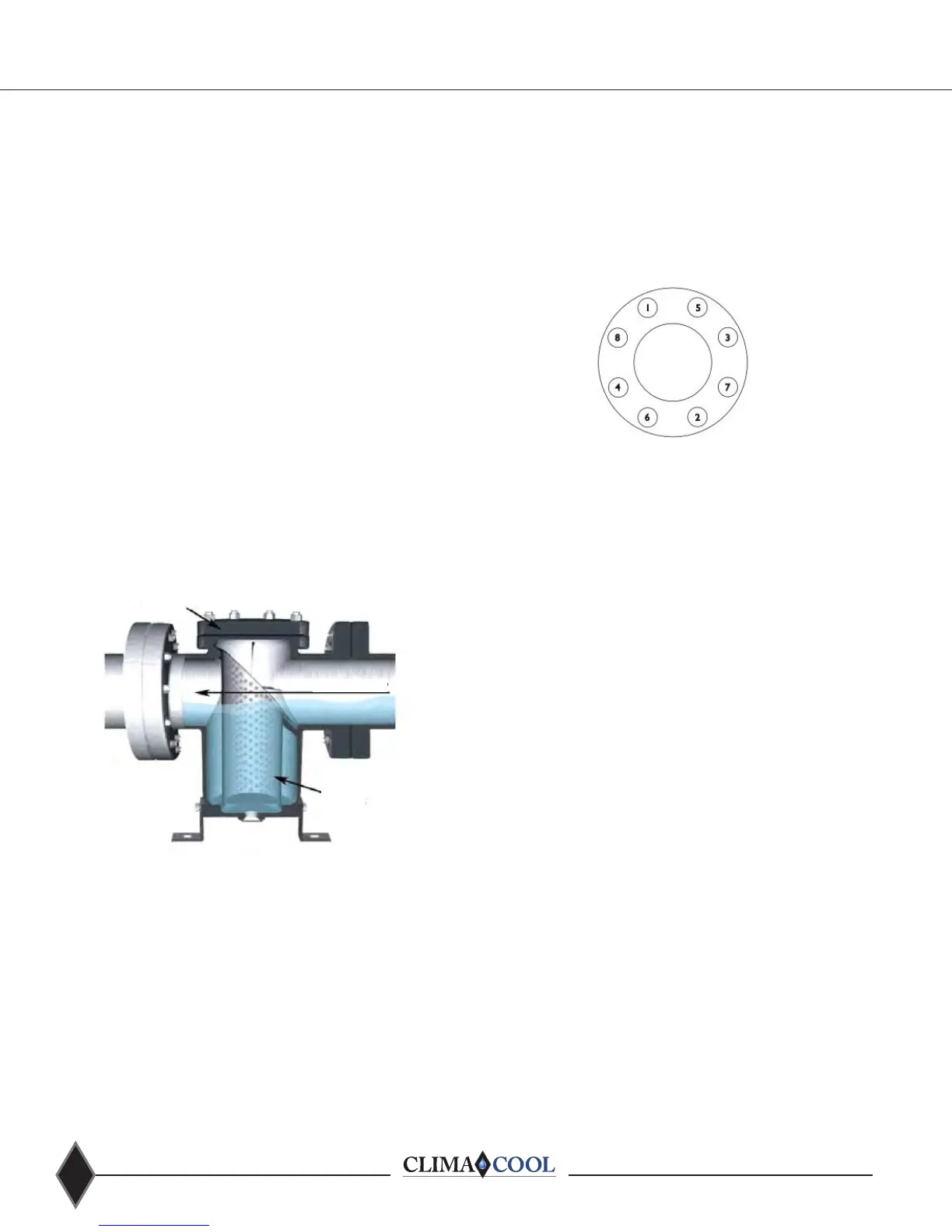

Figure 37: Bolting Sequence Pattern

Note: Excessive bolt torque may damage anges. Please

refer to established ange bolt torques for guidelines.

Operation

Once proper installation has been successfully completed,

start the system gradually, at start up as well as after shut

down. This eliminates sudden shock to the strainer and

other equipment in the line. This is extremely important for

steam service.

Start-Up Procedure

1. Remove air from the pipeline by opening the vent near

the basket strainer. Note: With piping systems that

safe area, away from the operator. Operators should

gloves, vests etc.) when venting or servicing

is performed.

2. Start the piping system by opening the outlet valve

open the inlet valve nearest the basket strainer’s

It is important to start the system gradually to avoid

displacing or damaging the basket strainer.

3. Continue to open the inlet valve until the desired service

Basket

Strainer

Cover

Basket

Strainer

Screen

Pipeline Flow

4.

tighten. Flange bolts should then be tightened, using

a star or crisscross pattern to evenly load the bolts, in

accordance with established piping standards. This is

illustrated in Figure 37.

Start the piping system by opening the outlet valve nearest

inlet valve nearest the basket strainer’s inlet, approximately

system gradually to avoid displacing or damaging the basket

strainer. Continue to open the inlet valve until the desired

Loading...

Loading...