®

www.climacoolcorp.com

48

Pre Installation Checklist:

1.

in determining these values.

2. Inspect all sealing surfaces to ensure gasket surfaces

should also be checked for proper alignment. WYE

strainers should never be utilized to realign an existing

piping system.

3.

type as the WYE strainer being installed. Raised face

4. Ensure strainer end-to-end length and installation

clearance for easy opening of cover and screen removal.

5. If the WYE strainer is to be located on the discharge side

of a pump, then a safety release valve must be installed

between the WYE strainer and the pump.

Figure 34: WYE Strainer - Flanged Ends

WYE Strainers

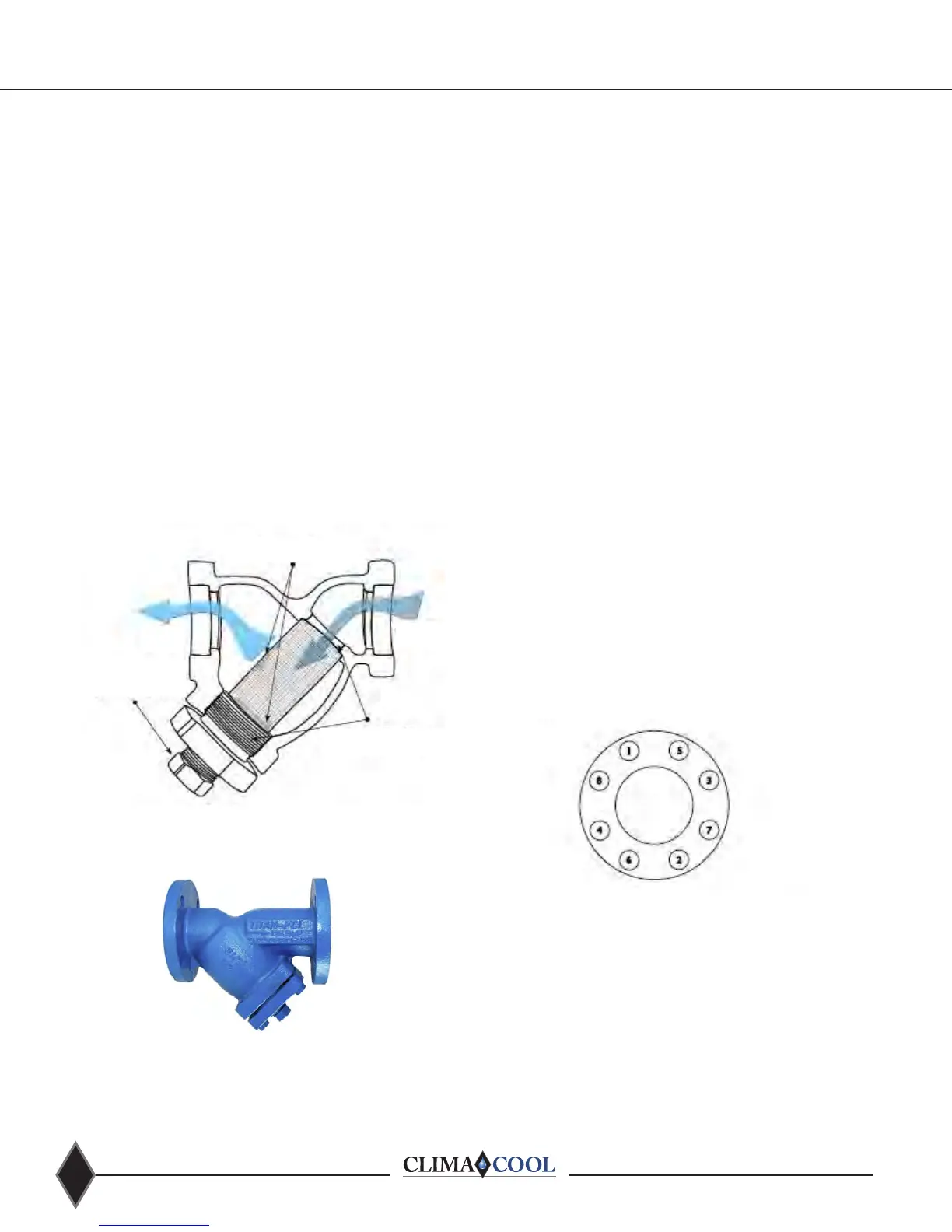

Figure 33: WYE Strainer Straining Illustration

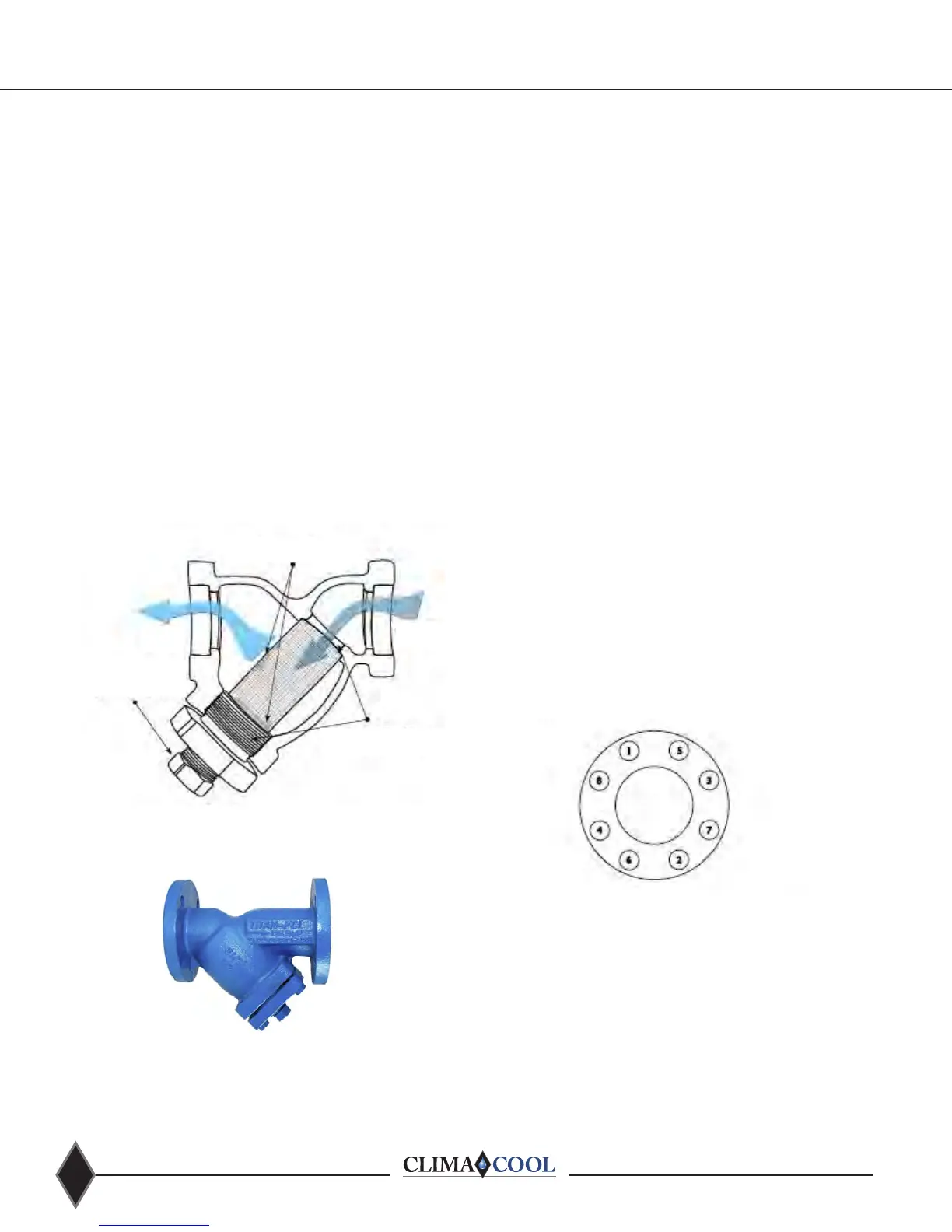

Figure 35: Bolting Sequence Pattern

Note: Excessive bolt torque may damage anges. Please

refer to established ange bolt torques for guidelines.

Installation Procedure:

1.

pressure gauge at inlet and outlet connections or at the

2. WYE strainers must be positioned in the pipeline ahead

of the equipment requiring protection.

3. To provide for easier maintenance, the WYE strainer

should be located where the drain plug can be removed.

the lowest position when installed. If installed in the

vertical position, the WYE side of the strainer must be

pointing downward.

4. Ensure there is ample space at the WYE side of the

strainer for screen removal.

5. Before placing the WYE strainer into place, support the

existing pipeline with pipe supports near the inlet and

outlet connections.

6. Place the WYE strainer into the pipeline ensuring

large or heavy strainers, appropriate material handling

equipment must be used.

7.

tighten. Flange bolts should then be tightened, using

a star or crisscross pattern to evenly load the bolts, in

accordance with established piping standards. This is

illustrated in Figure 35.

High Particle Retention

& Accumulation Areas

Flitered

Flow

Unitered

Flow

Machined Seats and Caps

for Fine Filtration

Manual or Automated

Valve Mounted to Blow O

Enables Self Cleaning

Operation

Once proper installation has been successfully completed,

start the system gradually, at start up as well as after shut

down. This eliminates sudden shock to the strainer and

other equipment in the line. This is extremely important for

steam service.

Loading...

Loading...