®

www.climacoolcorp.com

18

Hydronic Refrigeration

The ClimaCool Modular Chiller - Hydronic Configuration

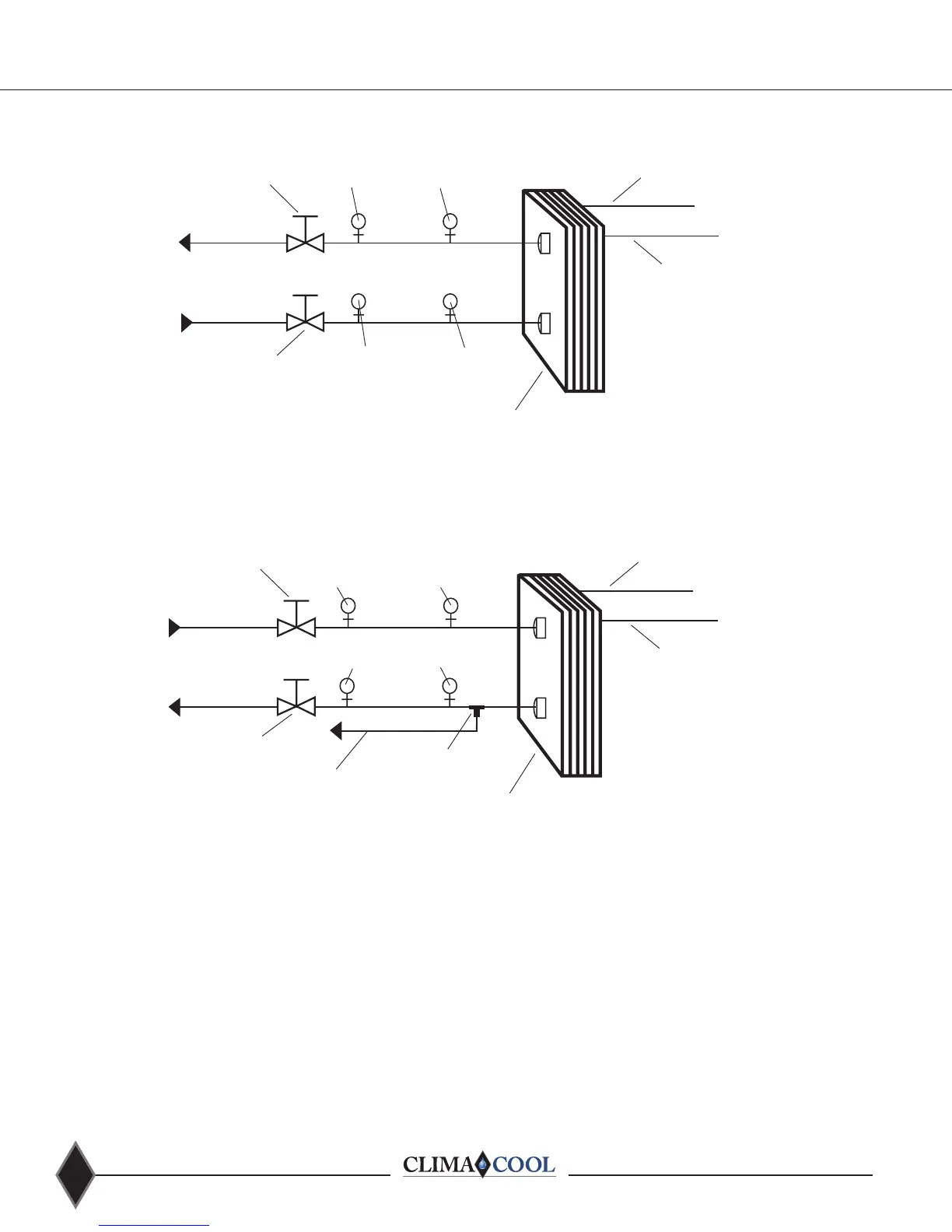

Figure 1 - Condenser Hydronic Circuit

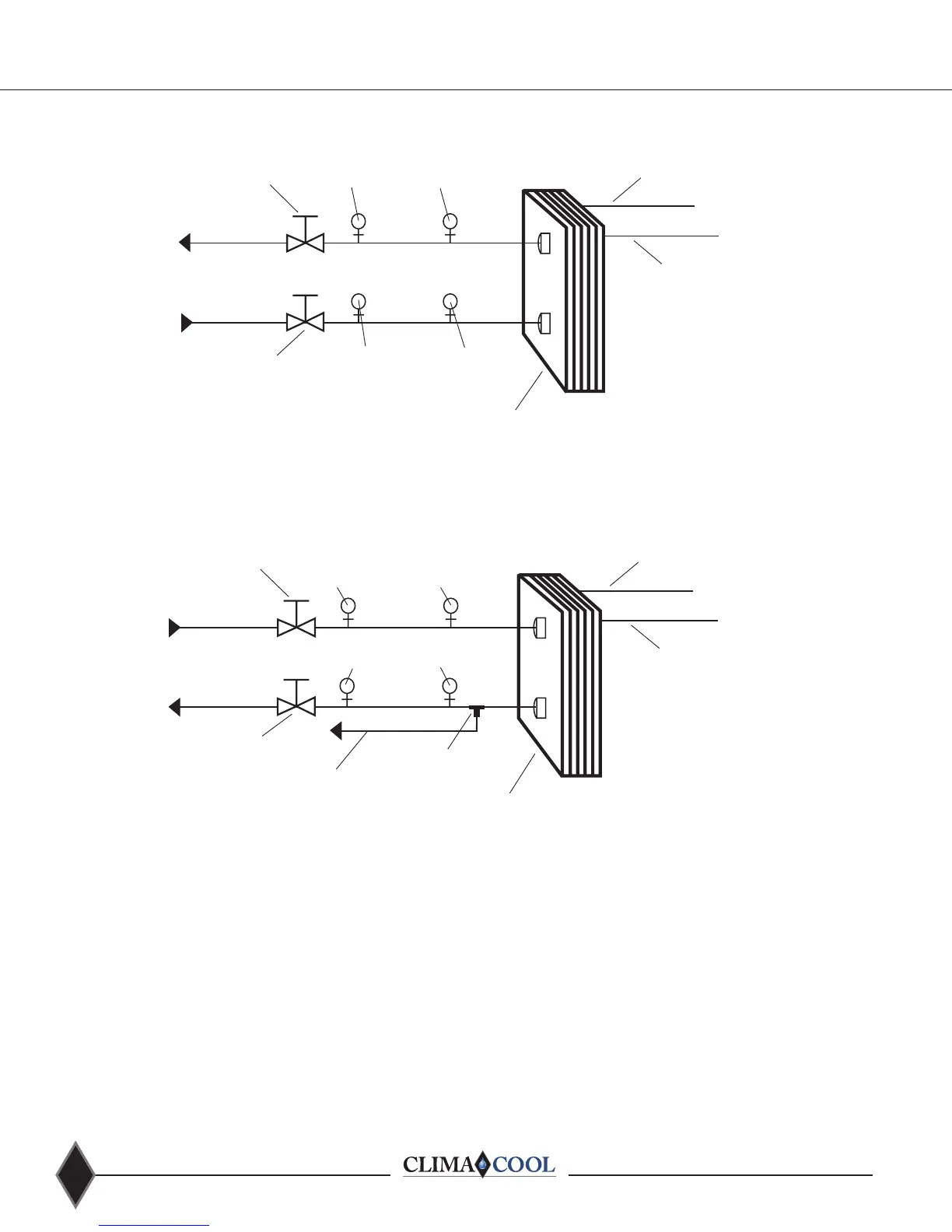

Figure 2 - Chilled Water Circuit

NOTE: Figures 1 and 2 depict hydronic piping in each ClimaCool chiller module.

Heat Exchanger

Refrigerant Circuit #1

Refrigerant Circuit #2

Service Port (3/4”)Pete’s Port

Pete’s Port

Service Port (3/4”)

From Cooling Tower

To Cooling Tower

Header

Header

Isolation Ball Valve (2, 2-1/2 or 3”)

Isolation Ball Valve (2, 2-1/2 or 3”)

Heat Exchanger

Refrigerant Circuit #1

Refrigerant Circuit #2

Service Port (3/4”)Pete’s Port

Service Port (3/4”)

Chilled Water Outlet

Chilled Water Inlet

Sensor Well (internal)

Cap Tube to Low Limit

Protection Thermostat

Header

Header

Isolation Ball Valve (2, 2-1/2 or 3”)

Isolation Ball Valve (2, 2-1/2 or 3”)

Pete’s Port

The ClimaCool Modular Chiller - Hydronic Configuration

Figure 1 - Condenser Hydronic Circuit

Figure 2 - Chilled Water Circuit

NOTE: Figures 1 and 2 depict hydronic piping in each ClimaCool chiller module.

Heat Exchanger

Refrigerant Circuit #1

Refrigerant Circuit #2

Service Port (3/4”)Pete’s Port

Pete’s Port

Service Port (3/4”)

From Cooling Tower

To Cooling Tower

Header

Header

Isolation Ball Valve (2, 2-1/2 or 3”)

Isolation Ball Valve (2, 2-1/2 or 3”)

Heat Exchanger

Refrigerant Circuit #1

Refrigerant Circuit #2

Service Port (3/4”)Pete’s Port

Service Port (3/4”)

Chilled Water Outlet

Chilled Water Inlet

Sensor Well (internal)

Cap Tube to Low Limit

Protection Thermostat

Header

Header

Isolation Ball Valve (2, 2-1/2 or 3”)

Isolation Ball Valve (2, 2-1/2 or 3”)

Pete’s Port

Note: Figure 21 and 22 depict hydronic piping in each ClimaCool chiller module and are shown with water isolation valves.

Figure 21- Condenser Hydronic Circuit

Figure 22 - Chilled Water Circuit

Loading...

Loading...