INSTALLATION

6

SeeleyInternationalPtyLtd

Cooler location

Check the proposed cooler location, to ensure that it is structurally capable of supporting the weight of the cooler, or provide an

adequate alternate load bearing structure.

Always locate the cooler where it will receive a plentiful supply of fresh air; NOT in a recess where it may be starved for air or

where the air is polluted.

Air exiting the exhaust hood is warm and heavily laden with moisture. Ensure the cooler’s exhaust outlet location will not cause

corrosion or damage to other nearby items.

Allow adequate access to and around the cooler for maintenance. Provision must be made for access to electricity, water

supplies and drains. Note: Do you need to discuss the installation of items like safety anchor points with the customer?

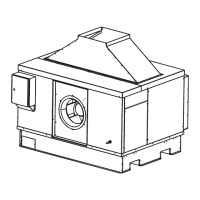

• Ensure the location is a minimum of:

3.0m from a solid fuel heater flue,

1.5m from a gas flue,

5.0m from a sewer vent

Rear = Min from a wall, at sides

to allow easy access for maintenance and core replacement.

!

!

!

!

Do not allow exhaust air to re-circulate into the air intake of the cooler.

1.0m 1.6m

Mounting/support

Unpackingthecooler

Movingthecooler

Liftingthecooler

Vibrationisolation

Industrystandardsupportframescanbeusedwiththiscooler.

Recommendedsteelspecification:

50*50*3mmRHSGalvanisedorPainted

Thecoolerwillbedeliveredwrappedinaplasticstretchwrapfilmwhichwillneedtoberemovedbeforeinstallation. A

smallbagofInstallationcomponentsalongwiththeexhausthoodsheetmetalcomponentscanbefoundunderthelidof

themaincabinetofthecooler. Thelidwillneedtoberemovedandtheexhausttransitioncomponentsassembledand

fittedtothelidbeforere-installingthelidassemblybackontothecooler. Thewallcontrolandcommunicationscable,

alongwithancillarymountplates,fastenersanddrainadaptorswillneedtobeplacedasideforlaterconnection.

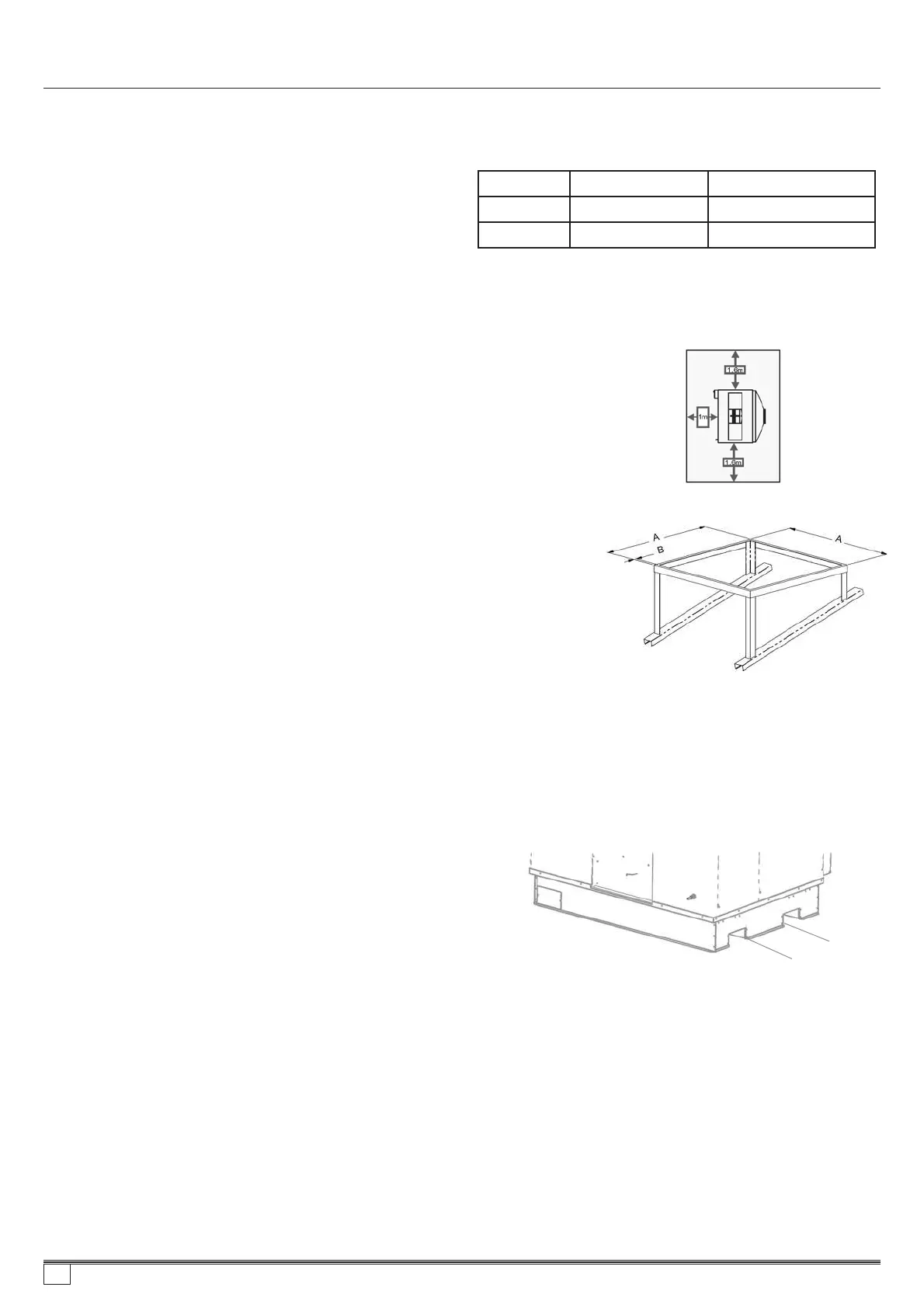

Thecoolerhasin-builtfork-trucktyneopeningsinthebaseforeaseofmovement. Theopeningscanalsobeusedwith

liftingstrapsorslings(referdiagram&seebelow)

Thecoolermaybeliftedeitherbyfork-truckorcranewithslings. Themethodforliftingbycraneisbyliftingstrapsthrough

thecoolerbasefork-trucktyneopenings.Donotattempttoliftusinganycabinetfeaturesorbyretro-fittingliftinglugs. The

cabinetmaybedamagedand/orliftsafetycompromised.

Itisrecommendedtouseaspreaderbaronthestrapsorslingsand/ortoprotecttheupperedgesofthecoolerwitha

cornerprotectorbeneaththeliftingstrapstoavoidanydamagetothecabinetduringthelift.

Wafflepadsarerecommendedtobeusedundereachcornerofthecooler.Padsizeapprox.200*200mm.Useindustry

standardmethodsoffixingtothebuildingstructure.

Min.Forktynegap

=460mm

CW-H10 A =1300*1206

1300*1800

CW-H10&15B=50min

Angletomatchroofpitch

CW-H15 A =

Model

CW-H10 180kg 220kg

265kg225kgCW-H15

ShippingWeight OperatingWeight

859736-A AU1007

Loading...

Loading...