A radiator for cooling the hydraulic circuit oil and a

biodegradable hydraulic oil can be provided as *op-

tional. In case of its refill or replacement, it is impera-

tive to comply with the technical specifications of the

product already present in the system.

To check these pressures, it is necessary to be

equipped with a manometer. Make sure that the ma-

chine is closed and in the rest position and that no-

body is present in the machine's operating range.

Visually inspect all hoses, fittings and all other com-

ponents of the hydraulic system in order to identify

any possible leaks. Normally, leaks on the pipes can

be eliminated by correctly tightening the fittings. If

leaks in the sealing areas (o-rings, sealing rings,

etc.), the restoration of the seal can only be carried

out by replacing the gasket.

All the operations requiring the interven-

tion on the components of the machine,

shall be carried out by authorized and

trained technical staff.

Non-authorized staff shall not replace any

components. Many components have been

calibrated: a correct calibration of these

parts (only in CMC or in authorized Ser-

vices) is necessary to ensure the safety of

the machine.

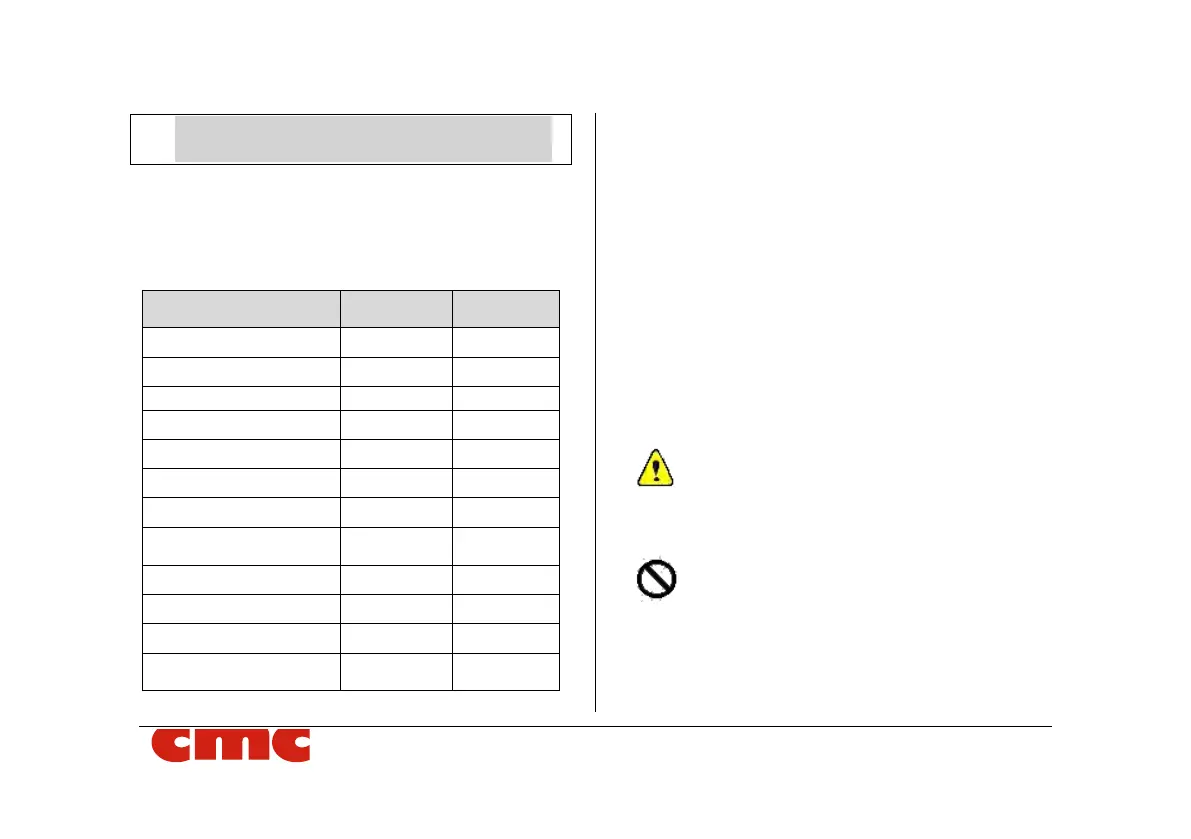

Loading...

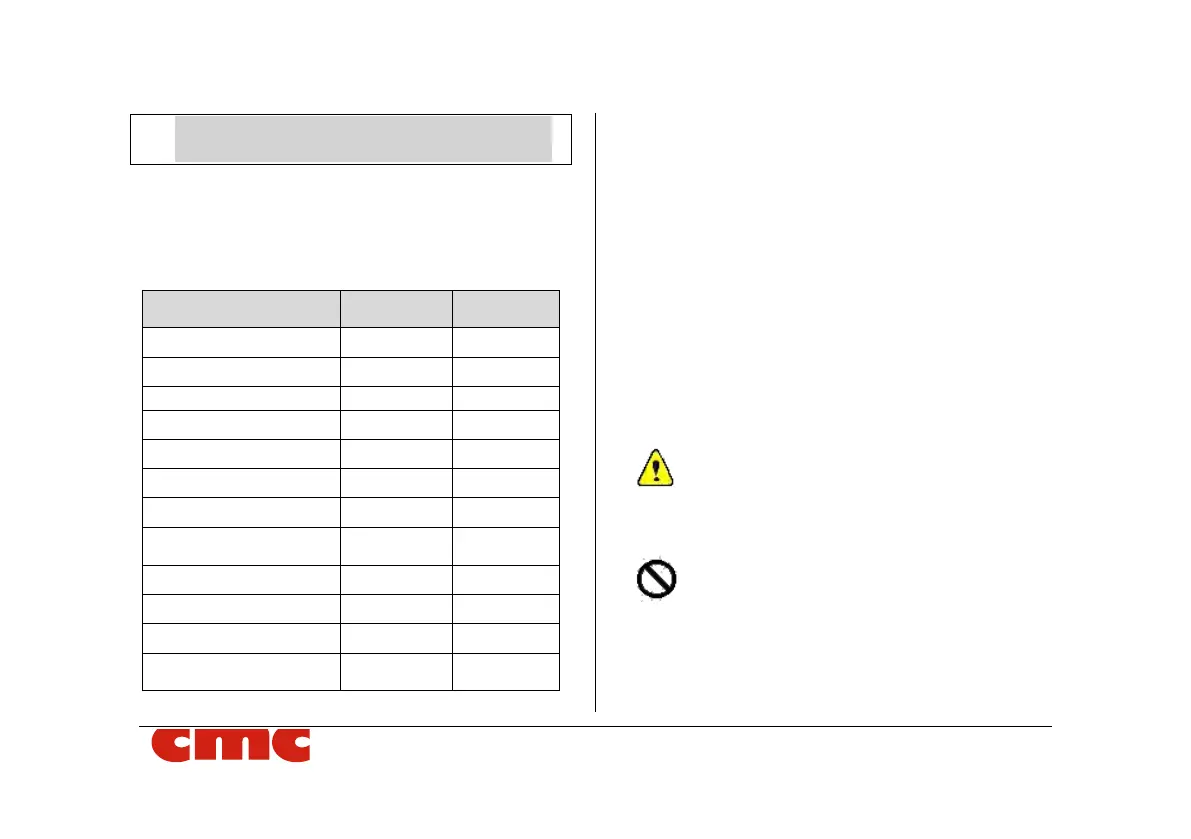

Loading...