13

MACHINE PREPARATION

7. SQUEEGEE

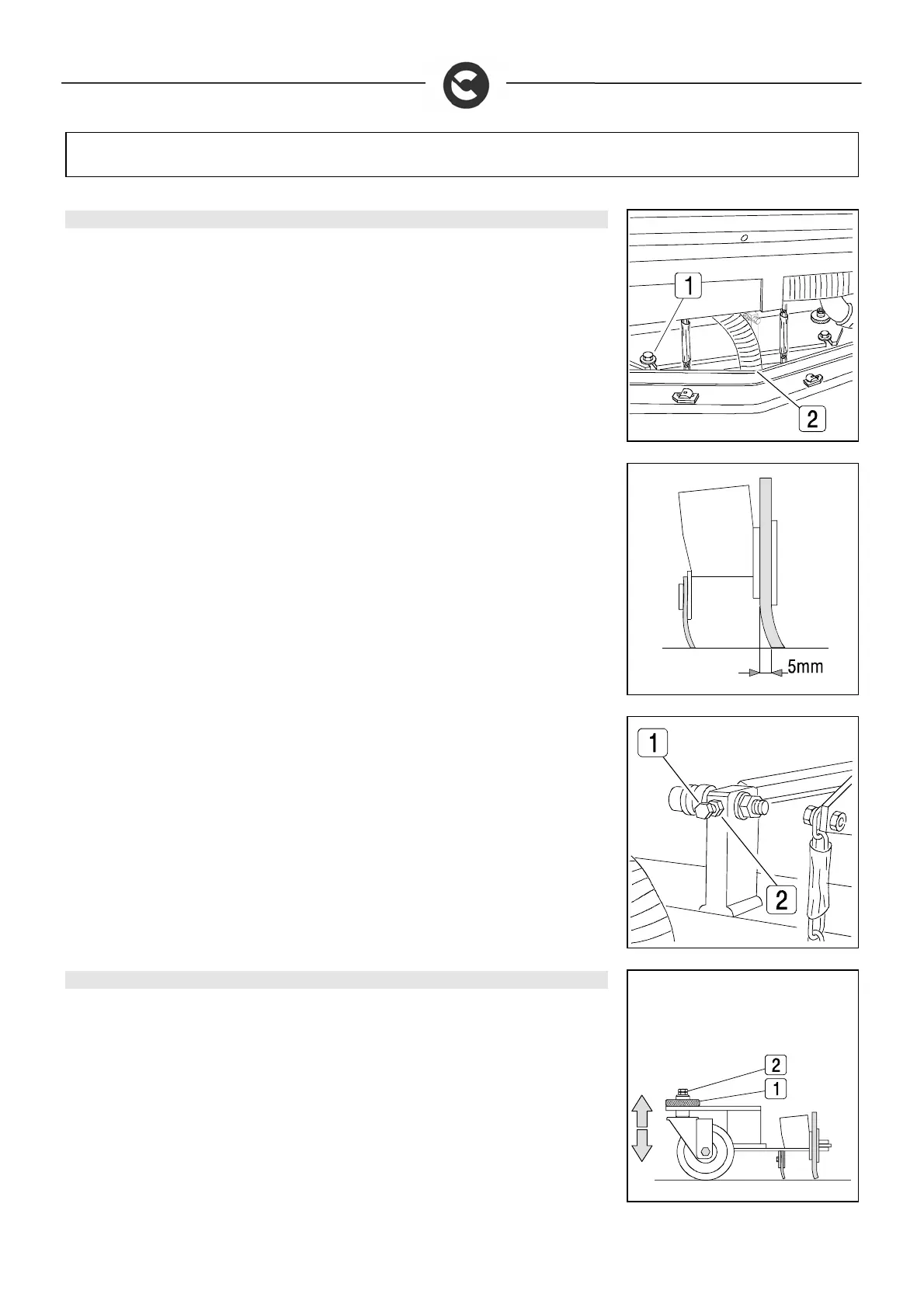

For packaging reasons, the squeegee is supplied disassembled. It must be assembled as

shown in the figure, inserting its screws (1) in the special housings on the squeegee support

and fixing it with a CH17 spanner.

Insert the suction tube (2) in the sleeve and fix it with the special clamp.

During working operation, the rear rubber is slightly tilted backwards (by about 5mm) in a

uniform way for its whole length.

If it is necessary to increase the bend of the rubber in the central part, you must tilt the

squeegee backwards, loosening the locknut (2) and turning the screw (1) anticlockwise. To

increase the bend of the rubber at the sides of the squeegee, loosen both the locknut (2) and

the screw (1). When fully adjusted, fix the locknut. These operations can be carried out with the

aid of a CH13 spanner.

8. ADJUSTING THE SQUEEGEE SUPPORT HEIGHT

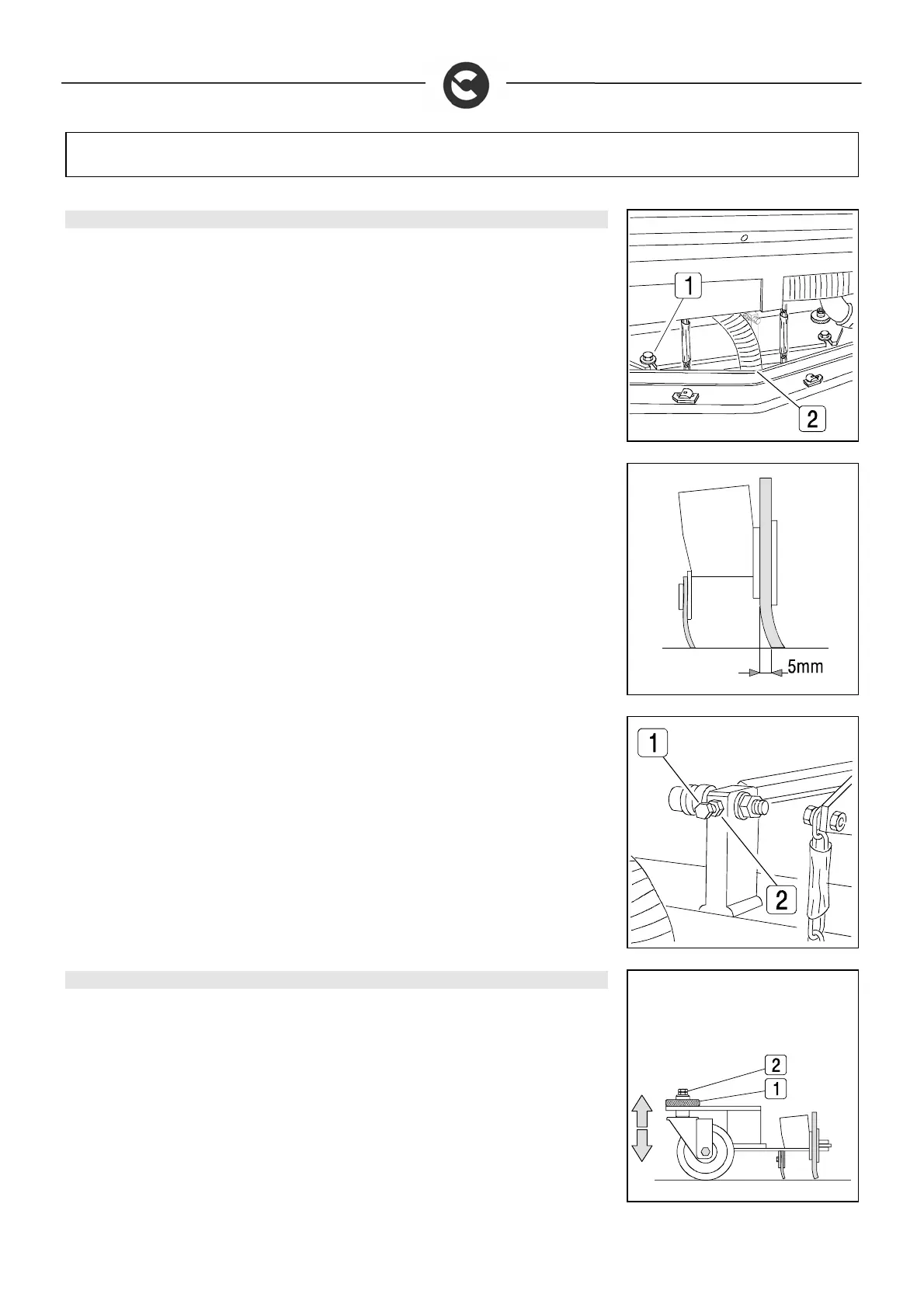

The height of the squeegee must be adjusted on the basis of the state of wear and tear of the

rubber. Proceed as follows:

1. loosen the ring nut (1)

2. use a CH17 spanner to turn the pivoting wheel, via the nut (2), clockwise to lift the

squeegee and anticlockwise to lower it

3. fix the ring nut (1)

NB: the left and right pivoting wheels must be adjusted to the same height

Loading...

Loading...