7

Conventional Wheel Hubs – Recommended Service

ConMet

4. Conventional Wheel Hubs – Recommended Service

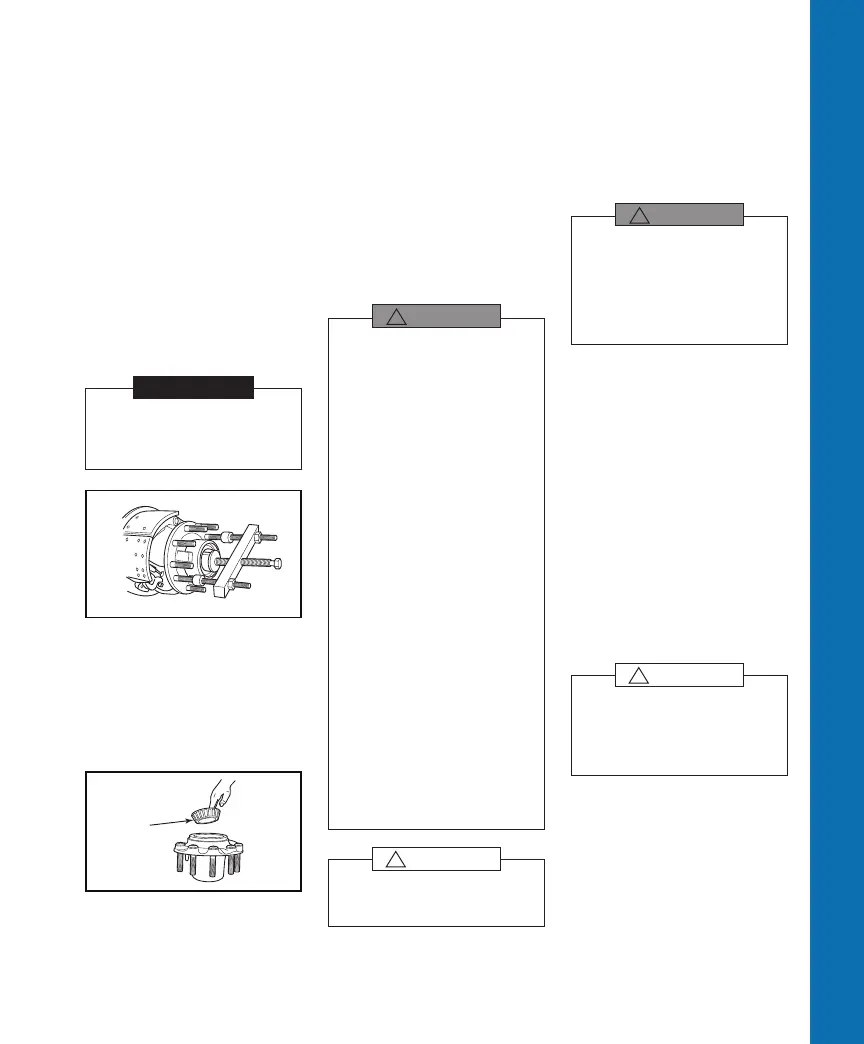

10. Slide the hub off the spindle.

Remove and save the outer

bearing cone. Be careful when

you remove the hub that you do

not damage the outer bearing

by dropping it on the oor.

- If the hub is difcult to remove

because the seal or bearings

are stuck on the spindle, use

a mechanical puller to remove

the hub (see gure 25).

- If part of the seal remains on

the spindle, carefully remove

the part of the seal that

remains on the spindle.

This can be done by striking the remaining portion

of the seal with the round end of a ball-peen

hammer. Use caution not to damage the seal

journal on the spindle.

NOTE

105740a

FIGURE 25

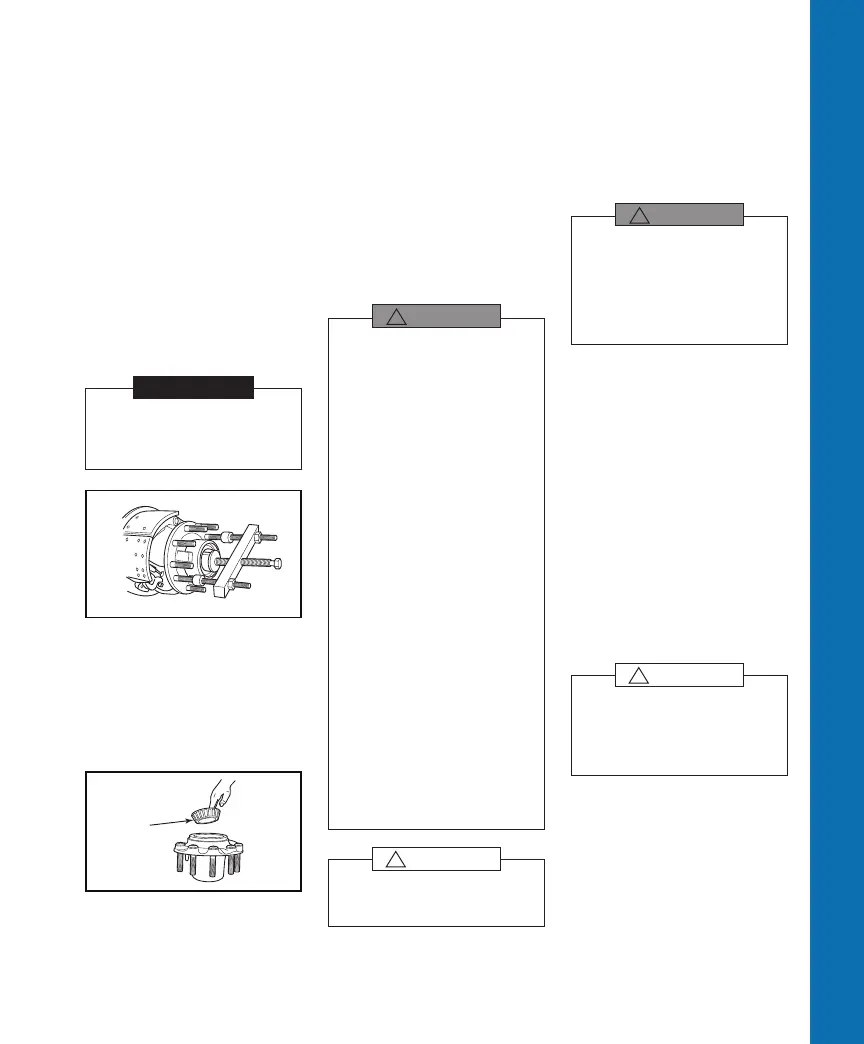

11. Place the hub on its outboard

end and remove the seal.

Retain the seal if it needs

to be returned for warranty

consideration.

12. Remove the inner bearing cone

(see gure 26).

INNER

BEARING

CONE

Hub Disassembly

FIGURE 26

COMPONENT

INSPECTION AND

REPLACEMENT HAZARD

ALERT MESSAGES

Read and observe all hazard alert

messages in this publication. They

provide information that can help

prevent serious personal injury,

damage to components, or both.

To prevent serious eye injury, always wear

safe eye protection when you perform vehicle

maintenance or service.

Observe all warnings and cautions provided

by the press manufacturer to avoid damage to

components and serious personal injury.

Do not hit steel parts with a steel hammer. Pieces

of a part can break o. Serious personal injury and

damage to components can result. Use a brass or

synthetic mallet for assembly and disassembly

procedures.

Solvent cleaners can be ammable, poisonous

and cause burns. Examples of solvent cleaners

are carbon tetrachloride, and emulsion-type

and petroleum-base cleaners. Read the

manufacturer’s instructions before using a solvent

cleaner, then carefully follow the instructions. Also

follow the procedures below.

- Wear safe eye protection.

- Wear clothing that protects your skin.

- Work in a well-ventilated area.

- Do not use gasoline or solvents that contain

gasoline. Gasoline can explode.

- You must use hot solution tanks or alkaline

solutions correctly. Read the manufacturer’s

instructions before using hot solution tanks

and alkaline solutions. Then carefully follow

the instructions.

WARNING

!

Do not use hot solution tanks or water and

alkaline solutions to clean ground or polished

parts. Damage to parts can result.

CAUTION

!

CLEAN AND DRY

COMPONENTS

Worn or Damaged Components

Do not repair or recondition wheel-end

components. Replace damaged, worn or out-of-

specication components. Do not mill or machine

any components. Using repaired, reconditioned,

damaged or worn components can cause wheel

end failure, which can result in serious injury and

property damage.

WARNING

!

Hub and Component Cleaning

1. Use a cleaning solvent to clean

the hub and all wheel end

components.

2. Do NOT clean ground or

polished parts in a hot solution

tank or with water, steam

or alkaline solutions. These

solutions will cause corrosion of

the parts.

3. Clean and inspect the wheel

bearing cups and cones,

race, spindle bearing and seal

journals on the spindle and hub.

Bearings should be cleaned

with clean ltered solvent and

dried with either compressed

air or a lint-free rag.

If compressed air is used, do not spin dry the

bearings. The rollers may score due to lack of

lubricant and rollers could come o which can

result in serious injury. Ensure that the air line is

moisture free.

CAUTION

!

4. Clean and inspect the spindle.

Be sure to clean the full length

of the seal journal on the

spindle.

5. Parts must be dried

immediately after cleaning. Dry

parts with clean paper towels or

rags, or compressed air. Do not

dry bearings by spinning with

compressed air.

Loading...

Loading...