PreSet Wheel Hubs – Recommended Service

20 ConMet

5. PreSet Wheel Hubs – Recommended Service

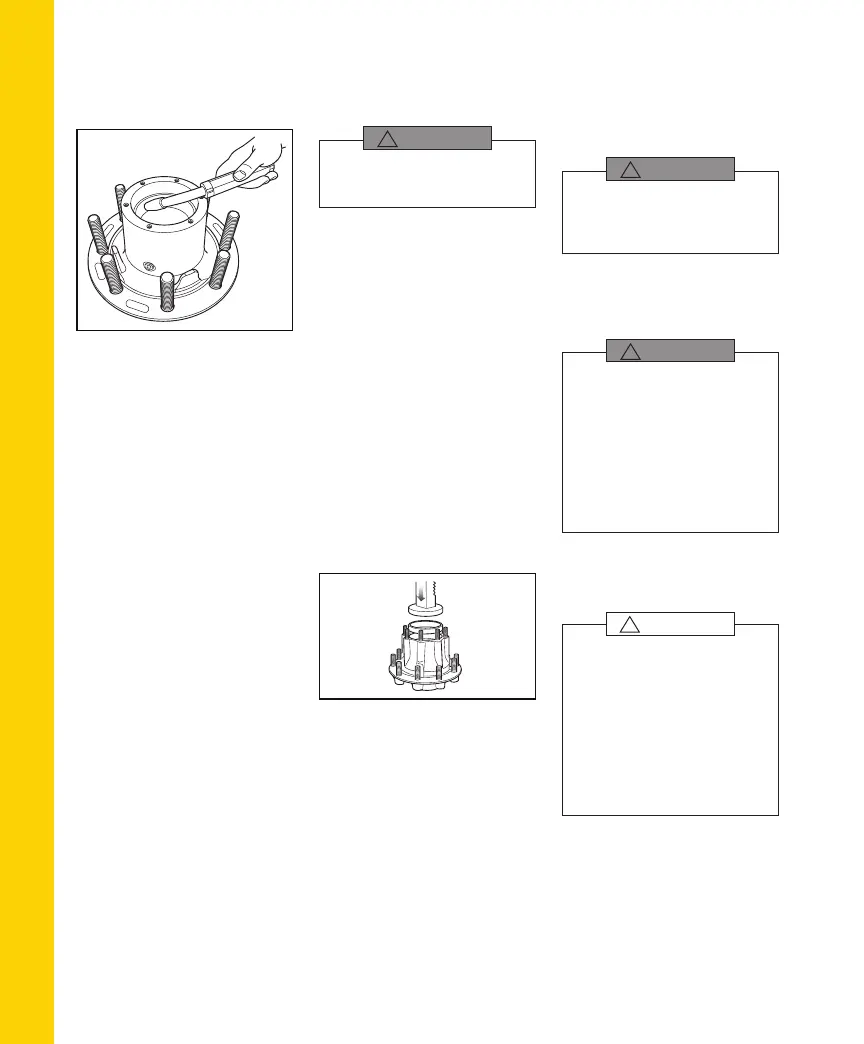

106856a

Welding Bead

FIGURE 46

2. Inspect the bearing cup bore

for evidence of cup rotation or

spun cups.

- If cup rotation exists, replace

the hub.

REMOVING CUPS IN

IRON HUBS

1. On an iron hub, remove the

bearing cup using a large

hammer and a mild steel bar

or a hydraulic press. Take

precaution to avoid damaging

the bearing cup bore and

shoulder.

2. Inspect the bearing cup bore

for evidence of cup rotation or

spun cups.

- If cup rotation exists, replace

the hub.

INSTALLING A NEW CUP

IN ALUMINUM HUBS

To install a new cup in an aluminum

hub, it is recommended that

the hub be heated in boiling

water (212°F) or in an oven at a

temperature not to exceed 300°F.

Cooling the cup in a freezer to

32°F or below will further ease the

installation.

Do not overheat the hub as it may degrade the

heat-treated strength of the hub. Do not heat the

hub with a torch or open ame.

WARNING

!

Remove the aluminum hub from the

oven or water and carefully drop in

the new bearing cup being certain

it is fully seated. If the cup is loose,

allow a few seconds for it to heat up

and secure itself before moving the

hub. Use a 0.001″ to 0.002″ feeler

gauge to ensure the cup is fully

seated against the shoulder of the

bearing bore.

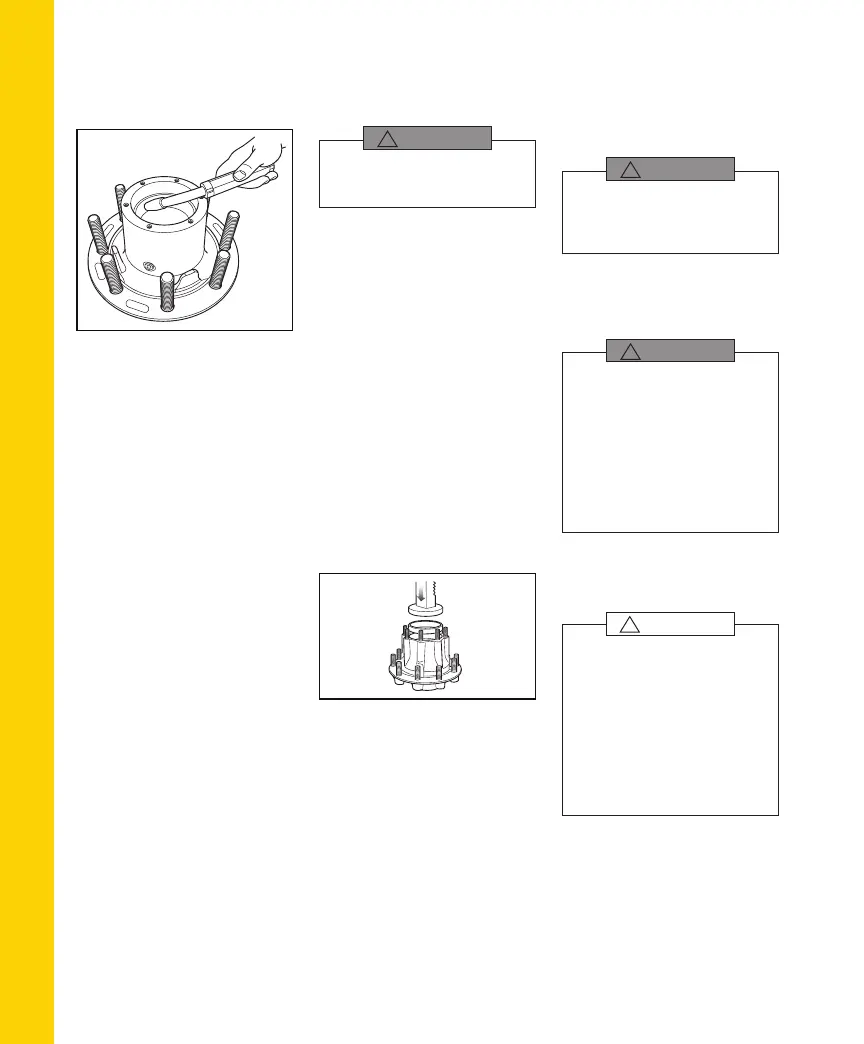

INSTALLING A NEW CUP

IN IRON HUBS

Iron hubs do not need to be heated

for bearing cup installation. Press

the bearing cup into the hub, being

certain that it is fully seated (see

gure 47). Use a 0.001″ to 0.002″

feeler gauge to ensure the cup is

fully seated against the shoulder of

the bearing bore.

105742a

Bearing Cup Pressed into Hub

FIGURE 47

WHEEL STUDS

Replace all wheel studs that have

damaged or distorted threads,

are broken or bent, or are badly

corroded. Also, replace both

studs adjacent to the damaged

stud. If two or more studs have

damage, replace all the studs in

the hub. Broken studs are usually

an indication of excessive or

inadequate wheel nut torque.

STUD REMOVAL

Observe all warnings and cautions for press

operation provided by the press manufacturer

to avoid serious personal injury and damage to

components.

WARNING

!

1. Place the clean hub in a shop

press with the hub supported

evenly around and adjacent to

the stud being removed.

Failure to adequately support the hub can result in

physical injury and/or damage to the hub.

Some hubs are congured so it is impractical to

have supports to prevent the hub from tipping

when force is applied to the stud. In this case,

support the hub on wood blocks on the oor and

use a heavy hammer to drive the studs out with

several sharp blows. Be careful to avoid damaging

the hub and components, particularly the seal

bore and the ABS tone ring.

WARNING

!

2. Press the stud out of the hub.

STUD REPLACEMENT

On the ball seat wheel mounting system, always

use left-handed threaded studs, which are gold in

color and have an “L” stamped on the end, in the

hub on the driver’s side of the equipment, and use

right-handed threaded studs, which are silver in

color and have an “R” stamped on the end, in the

hub on the passenger’s side of the equipment.

The ConMet part number is located on the head

of the stud. The same part number must be used

for replacement unless changing the drum or

wheel type.

CAUTION

!

1. To install a new stud, support

the hub evenly around and

adjacent to the stud being

installed.

2. Press the new stud all the way

into the hub. Be sure the stud

is fully seated and that the stud

head is not embedded into the

hub.

Loading...

Loading...