41ConMet

7. Lubrication

DRIVE HUB

LUBRICATION

Drive hubs can be lubricated by

installing one quart of oil through

the ll plug in the barrel of the hub.

The proper installation torque for the ll plug is

20-25 ft-lbs.

CAUTION

!

If no ll plug is present, the drive

hub can be lubricated by lifting the

opposite side of the axle 8" to allow

the lubricant to run down the axle

housing and into the hub assembly.

Elevate the axle for two minutes to

allow the lubricant time to ll the

hub. Repeat the process for the

opposite side of the vehicle. The

rear axle carrier should be lled to

the proper level to ensure adequate

lubricant is available to ll the

entire hub. Rell the carrier to the

proper level after this procedure is

completed.

STEER AND TRAILER

HUBS WITH OIL

LUBRICANT

Only use oil approved by the seal manufacturer

(see approved list from the seal manufacturer or

on www.conmet.com).

Some hubs are provided with a ll hole, located in

the barrel and between the bearings for adding

lubricant.

NOTE

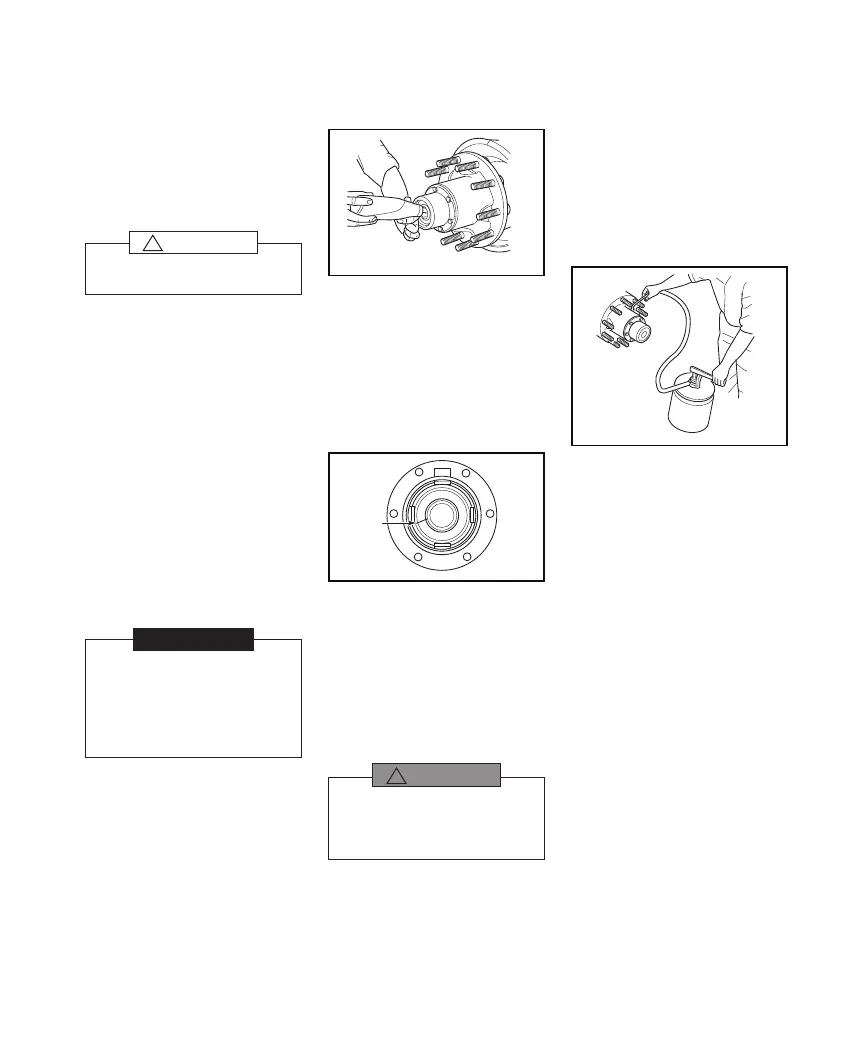

1. Fill the hub through the hubcap

or the ll hole with oil. It may

be necessary to add lubricant

more than once to adequately

ll the hub (see gure 86).

105753a

Filling the Hub with Oil

FIGURE 86

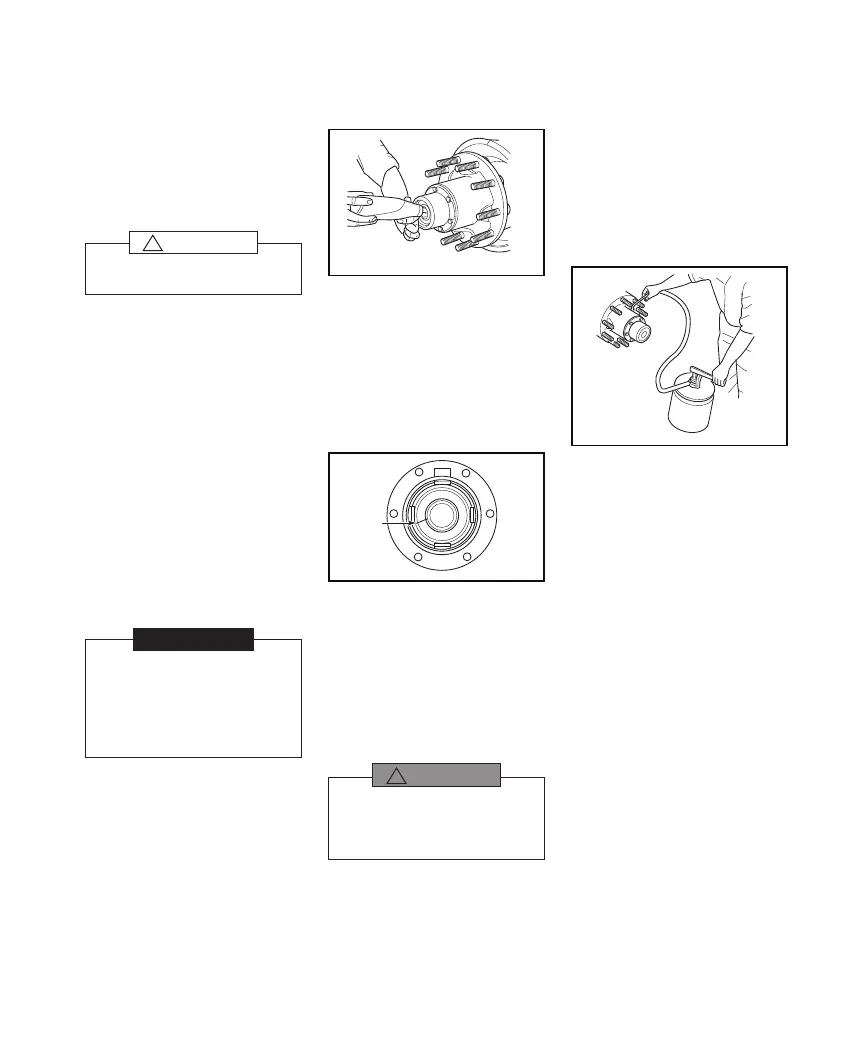

2. Be certain the hubcap is

properly lled to the “oil level”

mark on the face of the cap

(see gure 87). Allow the

initial ll amount to settle for

10 minutes. Repeat the ll

procedure until the oil is at the

ll line on the hubcap.

105754a

FULL

LINE

Fill to "Oil Level Line"

FIGURE 87

3. Be sure to put the ll hole plug

back into the hubcap and that

the vent is working properly.

TRAILER HUBS WITH

SEMI-FLUID GREASE

LUBRICANT

Failure to ll and maintain the hub with the

correct amount of semi-uid grease may cause

premature failure of the wheel hub system,

bearing failure and possible loss of the wheel.

WARNING

!

1. Remove the ll hole plug.

2. Loosen the hubcap bolts to

allow air to escape while the

hub is lling.

3. Fill the hub with the OEM

recommended amount of room

temperature (60°F minimum)

semi-uid grease through the ll

hole in the hub (see gure 88).

- For proper ll levels using

semi-uid grease, see the

chart on the next page.

105755a

Filling Hub with Semi-Fluid Grease

FIGURE 88

4. Retorque the hubcap bolts to

12-18 ft-lbs in a star pattern.

5. Reinstall and tighten the ll plug

to 20-25 ft-lbs.

Loading...

Loading...