PreSet Plus

®

Hub

Assemblies

ConMet PreSet Plus hub assemblies

feature the same PreSet technology

and include the same precision-

machined hubs, premium seals

and specially toleranced roller

bearings. However, PreSet Plus hubs

incorporate the following:

- An integrated spindle nut

that eases installation and

disassembly and protects

components during wheel end

service

- An optimized spacer

- Standard magnetic ll plug

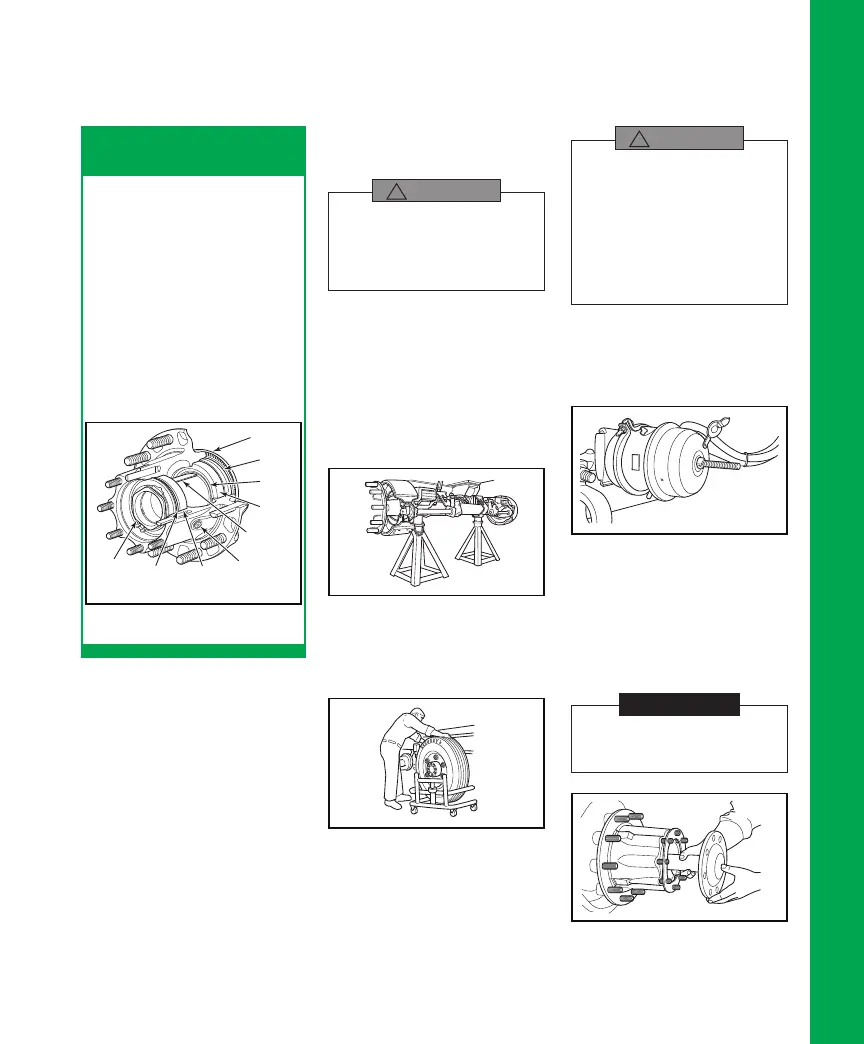

106922a

ABS RING

INNER

BEARING

CONE

INNER

BEARING

CUP

OUTER

BEARING

CUP

OUTER

BEARING

CONE

INTEGRATED

NUT

LUBRICANT

FILL PLUG

OIL SEAL

SPACER

(SECTIONED)

PreSet Plus Hub and Components

FIGURE 60

PreSet Plus Wheel Hubs – Recommended Service

29ConMet

6. PreSet Plus Wheel Hubs – Recommended Service

When inspections indicate that

service is necessary on a PreSet

Plus Hub, follow the recommended

service, inspection, reassembly

and reinstallation instructions found

in the following section.

In order to ensure optimum

wheel hub performance, ConMet

recommends that only approved

PreSet Plus service parts be used

to replace all critical components

of the system. Refer to the back of

this section for a listing of approved

parts.

HUB REMOVAL AND

DISASSEMBLY

Vehicles on jacks can fall, causing serious personal

injury or property damage. Never work under a

vehicle supported by a jack without supporting

the vehicle with stands and blocking the wheels.

Wear safe eye protection.

WARNING

!

1. Park the vehicle on a level

surface. Block the wheels

to prevent the vehicle from

moving.

2. Raise the axle until the tires are

off the oor.

3. Place safety stands under the

trailer frame or under each axle

spring seat (see gure 61).

FIGURE 61

4. Remove the tire and wheel

assembly using procedures

specied by the wheel

manufacturer (see gure 62).

103160a

FIGURE 62

Sudden release of compressed air can cause

serious personal injury and damage to

components.

Before you service a spring chamber, carefully

follow the manufacturer’s instructions to

compress and lock the spring to completely

release the brake. Verify that no air pressure

remains in the service chamber before you

proceed.

WARNING

!

5. If the axle is equipped with

spring brake chambers,

carefully compress and lock

the springs so that they cannot

actuate (see gure 63).

103161a

FIGURE 63

6. For drum brakes, remove

the brake drum. Support the

drum during the removal

process to prevent damage

to the components. For disc

brakes, remove caliper per

manufacturers’ recommended

procedure.

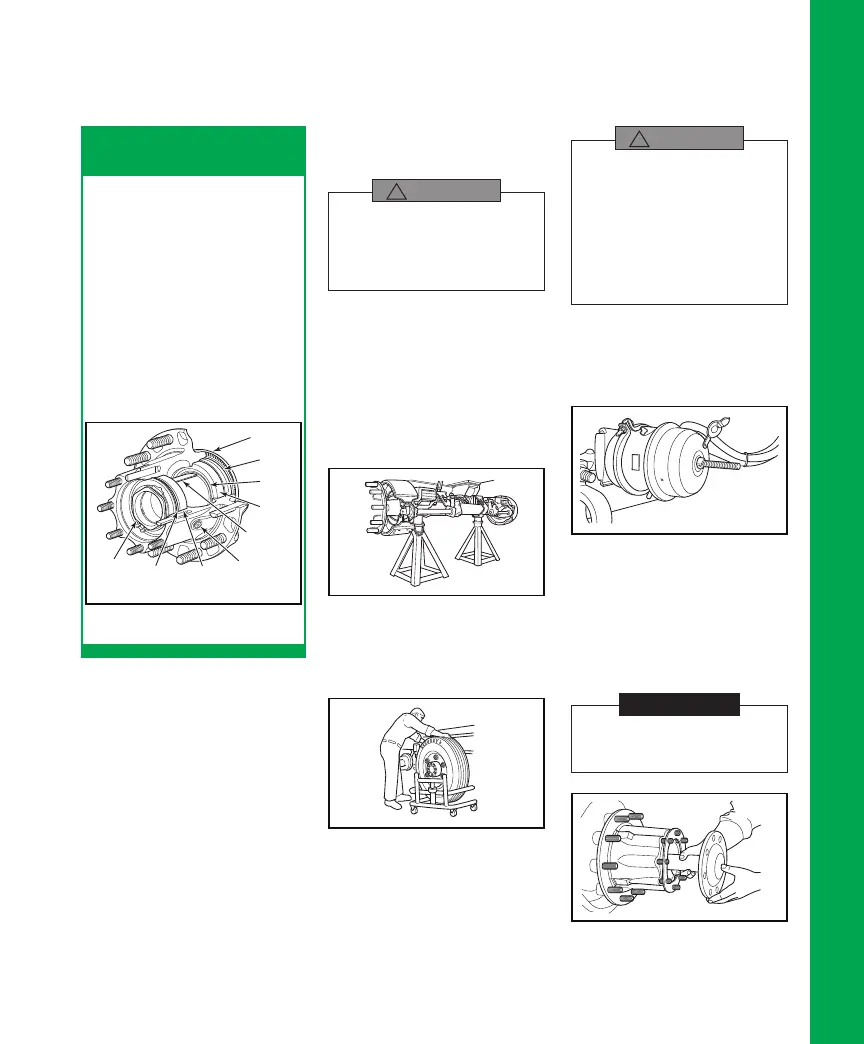

If the hub to be disassembled is a drive hub,

remove the drive axle shaft, and capture the oil

(see gure 64).

NOTE

106803a

Removing the Drive Axle Shaft

FIGURE 64

Loading...

Loading...