PreSet Plus Wheel Hubs – Recommended Service

32 ConMet

6. PreSet Plus Wheel Hubs – Recommended Service

1. After components have been

properly cleaned, visually

inspect the cups, cones and

spacer for any wear or damage.

Reference materials for proper

bearing inspection procedures

are available from the bearing

manufacturers.

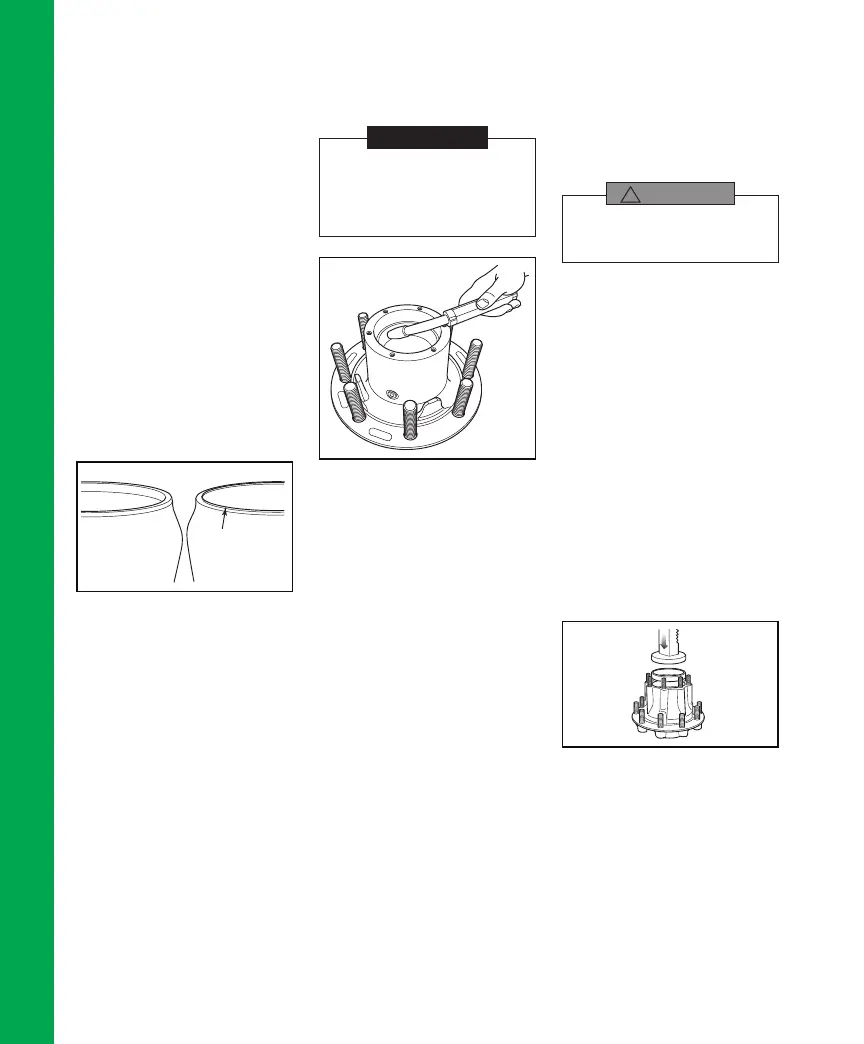

- Bearing spacers should be

visually inspected for signs

of wear or damage. Carefully

inspect the machined ends

of the bearing spacer. Wear

to the bearing spacer can

appear as a sharp ring of

standing metal at either edge

of the machined surfaces

(see gure 68). Replace the

spacer if it has visible wear

evidenced by a raised edge

on the machined end.

NEW WORN

SHARP

EDGE

Bearing Spacer Wear

FIGURE 68

2. If removal or replacement

is required, follow the steps

outlined below.

REMOVING CUPS IN

ALUMINUM HUBS

1. If the bearing cup must be

removed from an aluminum

hub, remove it by welding a

large bead around the bearing

surface of the steel cup,

letting the assembly cool, and

removing the bearing cup (see

gure 69).

If a welder is not available, heat the hub in an

oven to a temperature not to exceed 300°F and

pound out the bearing cups with a hammer

and mild steel bar, being careful not to damage

the hub.

NOTE

106856a

Welding Bead

FIGURE 69

2. Inspect the bearing cup bore

for evidence of cup rotation or

spun cups.

- If cup rotation exists, replace

the hub.

REMOVING CUPS IN

IRON HUBS

1. On an iron hub, remove the

bearing cup using a large

hammer and a mild steel bar

or a hydraulic press. Take

precaution to avoid damaging

the bearing cup bore and

shoulder.

2. Inspect the bearing cup bore

for evidence of cup rotation or

spun cups.

- If cup rotation exists, replace

the hub.

INSTALLING A NEW CUP

IN ALUMINUM HUBS

To install a new cup in an aluminum

hub, it is recommended that the hub

be heated in boiling water (212°F)

or in an oven at a temperature not to

exceed 300°F. Cooling the cup in a

freezer to 32°F or below will further

ease the installation.

Do not overheat the hub as it may degrade the

heat-treated strength of the hub. Do not heat the

hub with a torch or open ame.

WARNING

!

Remove the aluminum hub from the

oven or water and carefully drop in

the new bearing cup being certain

it is fully seated. If the cup is loose,

allow a few seconds for it to heat up

and secure itself before moving the

hub. Use a 0.001″ to 0.002″ feeler

gauge to ensure the cup is fully

seated against the shoulder of the

bearing bore.

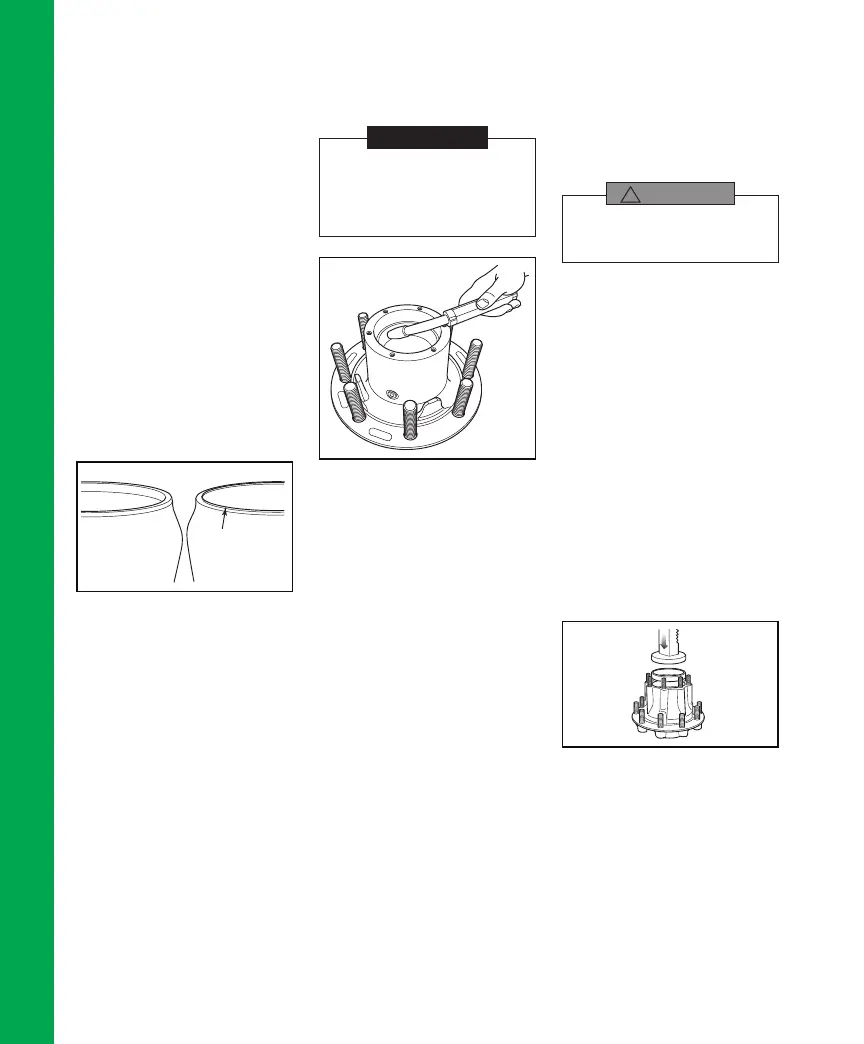

INSTALLING A NEW CUP

IN IRON HUBS

Iron hubs do not need to be heated

for bearing cup installation. Press

the bearing cup into the hub, being

certain that it is fully seated (see

gure 70). Use a 0.001″ to 0.002″

feeler gauge to ensure the cup is

fully seated against the shoulder of

the bearing bore.

105742a

Bearing Cup Pressed into Hub

FIGURE 70

WHEEL STUDS

Replace all wheel studs that have

damaged or distorted threads,

are broken or bent, or are badly

corroded. Also, replace both

studs adjacent to the damaged

stud. If two or more studs have

damage, replace all the studs in

the hub. Broken studs are usually

an indication of excessive or

inadequate wheel nut torque.

Loading...

Loading...