47ConMet

10. Hub and Rotor Inspection

HAZARD ALERT

MESSAGES

Read and observe all hazard alert

messages in this publication. They

provide information that can help

prevent serious personal injury,

damage to components, or both.

To prevent serious eye injury, always wear

safe eye protection when you perform vehicle

maintenance or service.

Do not work under a vehicle supported only by

jacks. Jacks can slip and fall over. Serious personal

injury and damage to components can result.

Park the vehicle on a level surface. Block the

wheels to prevent the vehicle from moving.

Support the vehicle with safety stands.

WARNING

!

Some brake linings contain asbestos bers, a

cancer and lung disease hazard. Some brake

linings contain non-asbestos bers, whose long-

term eects to health are unknown. Use caution

when handling both asbestos and non-asbestos

materials.

WARNING

!

DISC BRAKE ROTOR

INSPECTION

A disc brake component inspection

should be a part of any pre-trip

inspection and regularly-scheduled

preventive maintenance program.

Follow all shop safety procedures before

beginning vehicle inspection.

WARNING

!

1. Lift and support the axles

with safety stands. Refer to

the vehicle manufacturer's

recommended instructions.

2. Remove the wheels from the

hub.

3. Rotate the hub and visually

inspect both sides of the rotor

for the out of service conditions

detailed in this section. If any

of these conditions are found,

remove the hub and replace

the rotor according to the

instructions in this manual.

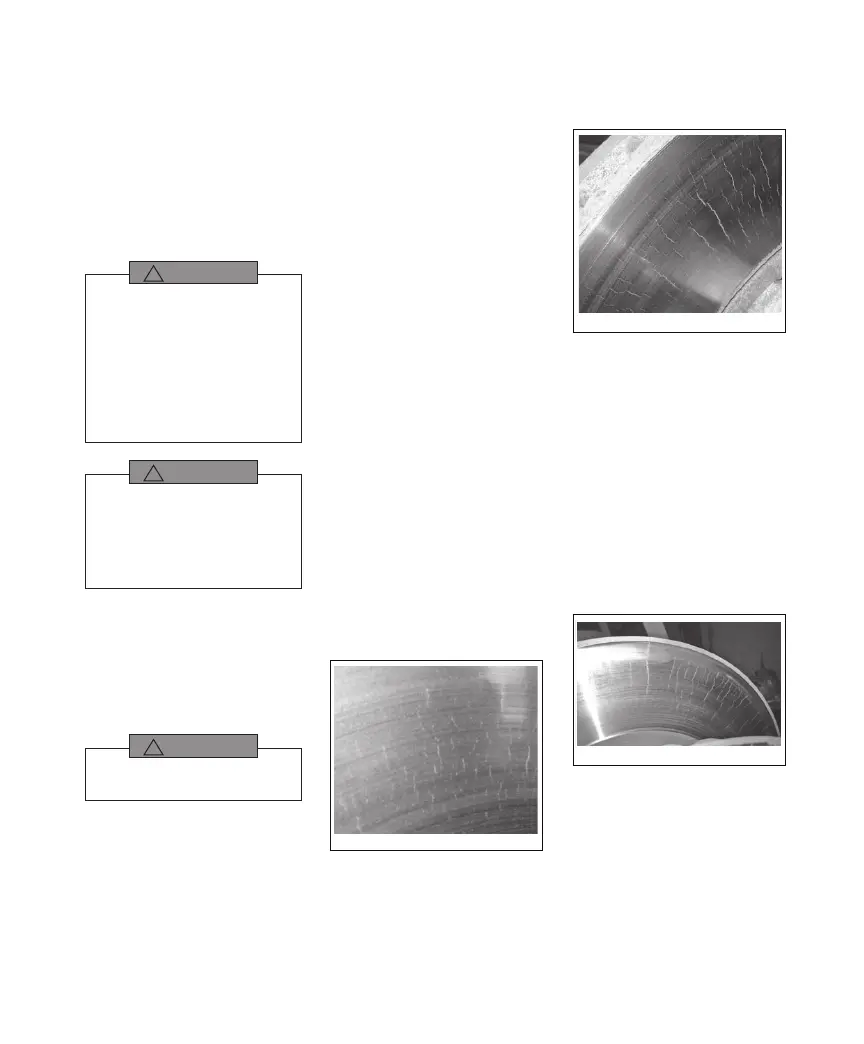

Heat Checks

Heat checks are caused by the

repeated heating and cooling of

the braking surface. They appear

as short, thin, radial interruptions

in the braking surface. There may

be numerous light and heavy heat

checks on the braking surface. See

gure 106 for examples of light heat

checking and gure 107 for heavy

heat checking.

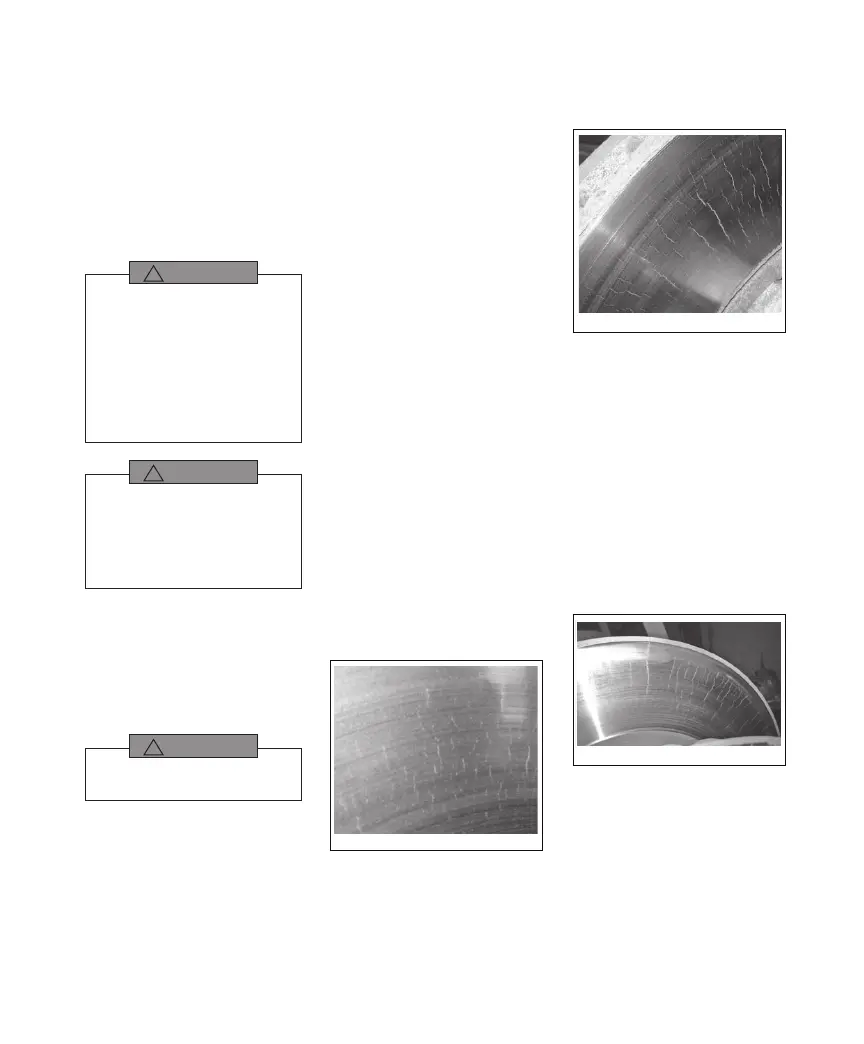

Cracks

Heat checks may wear away

or they may eventually become

braking surface cracks. Rotors

should be replaced if cracks

become over 0.060" wide or over

0.060" deep and extend over 75%

of the braking surface in the radial

direction.

106836a

Light Heat Check

FIGURE 106

106837a

Heavy Heat Check

FIGURE 107

Cracked rotors may be caused

by mishandling, brake balance

issues, wear beyond the minimum

allowable thickness, or driver

abuse. If a crack extends through a

section of the rotor, the rotor should

be replaced. If a crack is found

on the mounting section of the

rotor, the rotor should be replaced.

Figure 108 shows a cracked rotor

that should be replaced. The crack

in gure 109 is acceptable to run,

but the rotor should be inspected

on a regular basis to ensure that

the crack has not progressed.

106834a

Unacceptable Crack

FIGURE 108

Loading...

Loading...