3ConMet

2. Inspection (continued)

5. Check the lubricant condition.

Lubricant that is darkened,

milky, shows water in it or has

large metallic particles in it is

indicative of contamination

or a part failure and must

be replaced. Contaminated

lubricant may be an indication

of a leaking seal that should be

replaced.

- On oil lubricated hubs

equipped with a ll plug in

the hubcap or barrel of the

hub, place a magnet (or

inspect the magnetic ll plug)

in the lubricant and check

for signs of large metallic

particles picked up by the

magnet. On drive axles,

it is normal to nd a small

amount of very ne metallic

particles from the carrier

housing on the magnetic

ll plug. These particles

should be removed from the

magnet anytime the plug is

removed for inspection. If

larger particles or chunks

of metal are found, the hub

should be removed from the

spindle and the bearings and

other components should

be inspected for signs of

damage or excessive wear.

- In vehicles without a ll

plug in drive hubs inspect

the lubricant volume and

condition from the ll plug in

the axle carrier housing.

- For vehicles lubricated with

semi-uid grease, inspect

annually or every 100,000

miles. First, remove the

hubcap and inspect the

lubricant condition and

volume. Verify the lubricant

covers the ends of the

bearing rollers. If the lubricant

condition is good, add

lubricant through the ll plug

in the barrel of the hub to

cover the ends of the bearing

rollers. If the lubricant has a

dry and caked appearance,

remove the wheel end from

the vehicle and clean and

inspect all components.

Replace damaged or worn

components as necessary.

Rell hub with semi-uid

grease amount per chart on

page 42.

6. If regular scheduled

maintenance requires wheels/

axle to be lifted, perform steps

7 and 8.

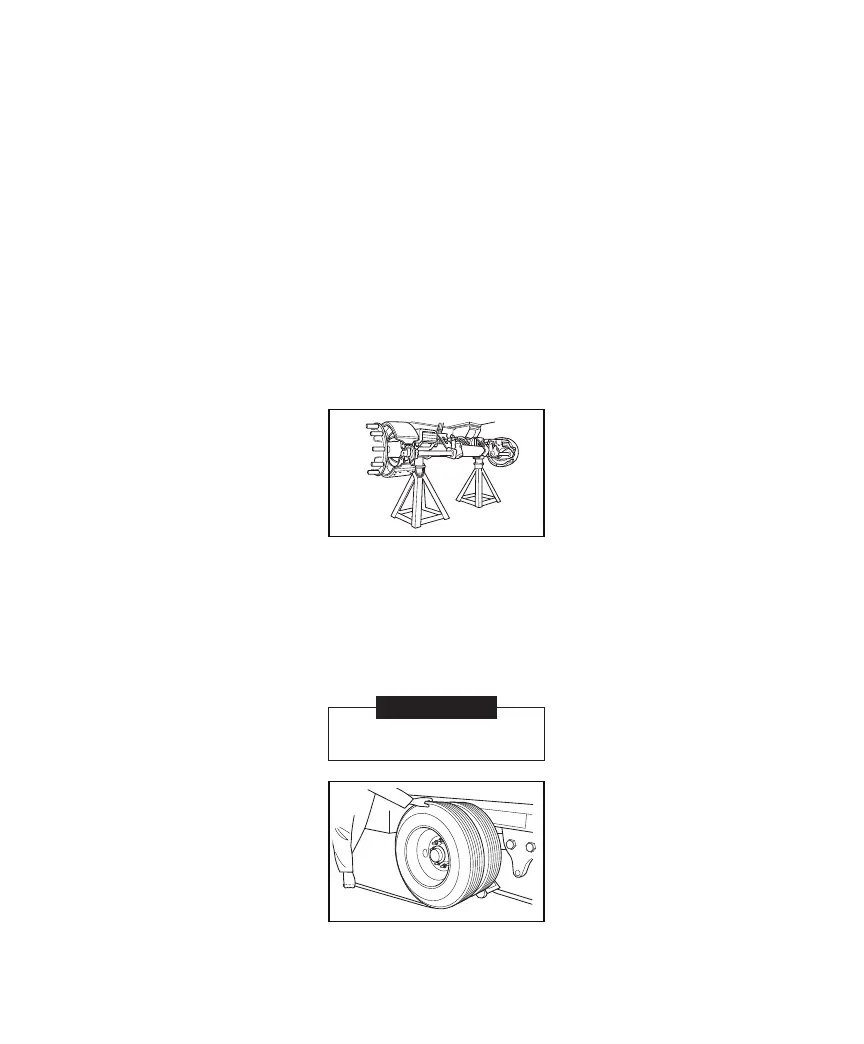

7. Lift and support the axle (see

gure 8). Rotate the wheel.

Check that the wheel rotates

freely and smoothly. Listen

and feel for any signs of rough

bearing operation or vibration.

1003159a

FIGURE 8

8. Place your hand on the top of

the tire and use a pry bar to lift

the bottom of the tire to check

for loose bearings or “chucking”

(see gure 9). If excess

movement or “chucking” is

found, wheel end service is

required.

Before you check for chucking, be sure to grease

the king pins.

NOTE

106878a

FIGURE 9

If any of the above conditions

are found, place the vehicle out

of service until the item can be

repaired.

Service Interval

Inspection results at driver pre-

trip, in-route and preventative

maintenance will indicate whether

further service is required.

When inspections indicate that

service is necessary, follow the

recommended service, inspection,

reassembly and reinstallation

instructions found in the following

sections of this manual.

Lubrication Analysis

Beyond the recommended visual

inspection and inspection with

a magnet, develop a lubrication

testing and replacement program.

This program will depend on

vehicle application, and lubrication

type. A lubricant supplier should

be consulted for additional

lubricant inspection and testing

recommendations.

Loading...

Loading...