51ConMet

11. Hub and Rotor Removal and Disc Replacement

HAZARD ALERT

MESSAGES

Read and observe all hazard alert

messages in this publication. They

provide information that can help

prevent serious personal injury,

damage to components, or both.

Do not work under a vehicle supported only by

jacks. Jacks can slip and fall over. Serious personal

injury and damage to components can result.

Park the vehicle on a level surface. Block the

wheels to prevent the vehicle from moving.

To prevent serious eye injury, always wear

safe eye protection when you perform vehicle

maintenance or service.

WARNING

!

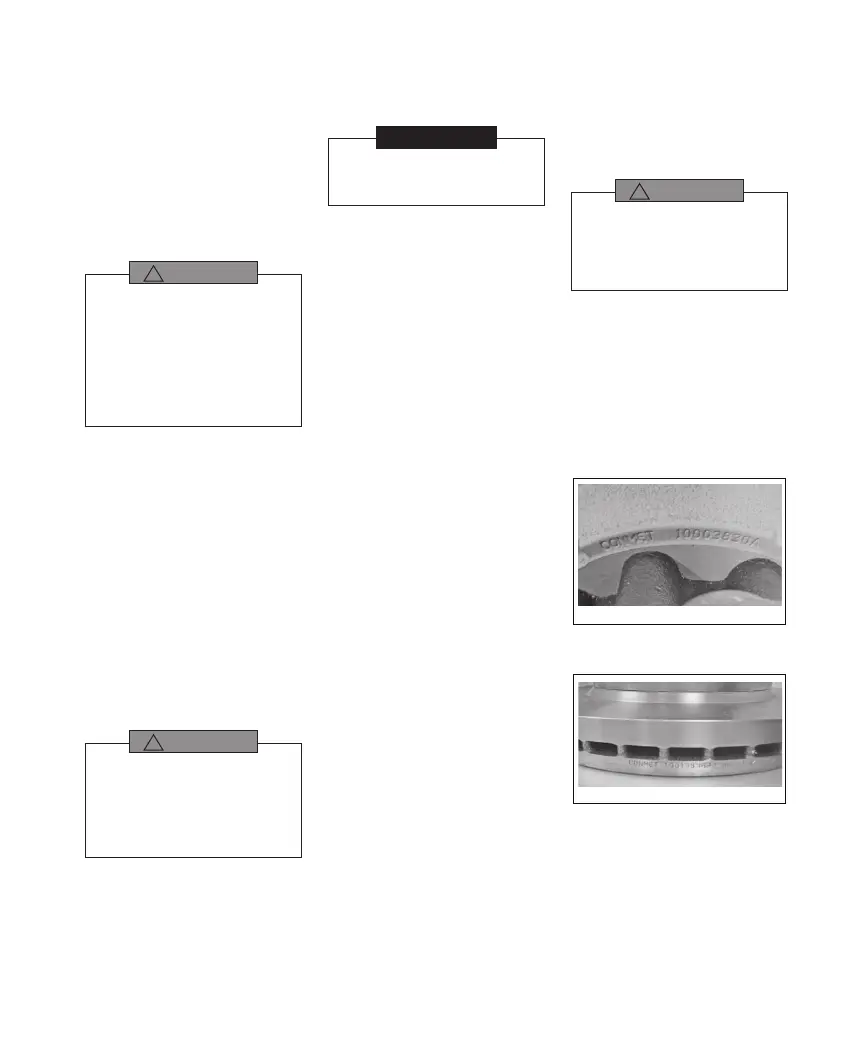

HUB AND ROTOR

REMOVAL

1. Lift the axle and support it

with safety stands. Refer to

the vehicle manufacturer's

recommended instructions.

2. Remove the tires and wheels.

3. Remove the hubcap or

drive axle. Refer to the

manufacturer's recommended

instructions.

4. Follow the brake manufacturer's

instructions to remove the brake

caliper and brake pads from

the axle mounting point.

Do not loosen the axle spindle nuts by either

striking them directly with a hammer, or striking

a drift or chisel placed against them. Damage to

the parts will occur causing possible loss of axle

wheel-end components and serious personal

injury.

WARNING

!

5. Remove the spindle nut

assembly.

Refer to Conventional, PreSet and PreSet Plus hub

removal procedures in this manual for specic

spindle nut removal instructions.

NOTE

6. Slide the hub and rotor

assembly off the spindle. Be

careful not to damage the outer

bearing.

7. Remove the bolts that secure

the rotor to the hub. Be careful

not to damage the ABS tone

ring when the rotor is removed.

8. Remove the seal from the hub.

9. Clean the bearing cups and

cones, bearing spacer, grease

cavity, and seal bore of the hub.

10. Inspect all components for

signs of wear or damage.

Replace components as

necessary.

11. Clean the spindle. It may

be necessary to remove the

inner portion of the seal from

the spindle. If necessary, use

emery cloth to remove rust and

foreign material from the seal

journal on the spindle.

12. Clean the rotor mounting area

of the hub.

DISC BRAKE ROTOR

REPLACEMENT

Do not hit steel parts with a steel hammer. Pieces

of a part can break o. Serious personal injury and

damage to components can result. Use a brass or

synthetic mallet for assembly and disassembly

procedures.

WARNING

!

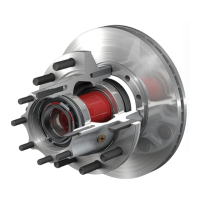

PART IDENTIFICATION

The brake rotor can be identied

by the part number that is cast or

stamped into the rotor. Use the

brake rotor part number to nd the

specic replacement instructions

for the hub and rotor assembly you

are working on (see gures 122

and 123).

106832a

Cast Part Number

FIGURE 122

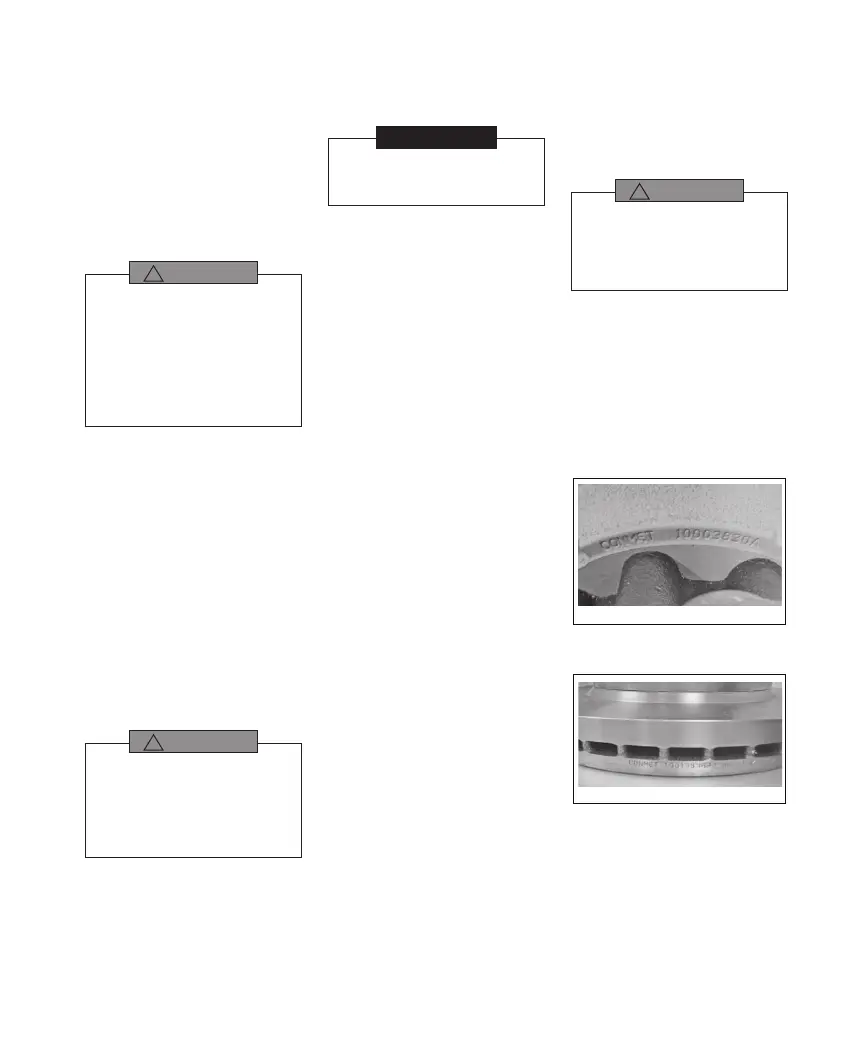

106848a

Stamped Part Number

FIGURE 123

Loading...

Loading...