13ConMet

Conventional Wheel Hubs – Reinstallation

4. Conventional Wheel Hubs – Reinstallation

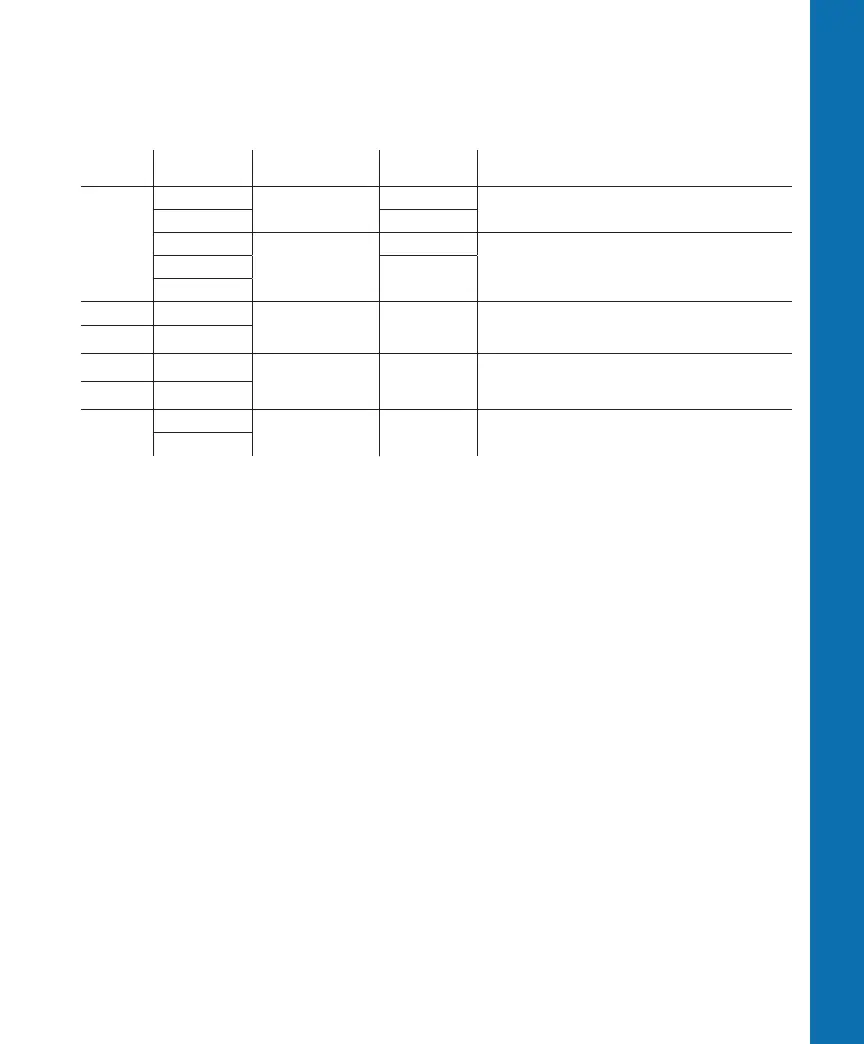

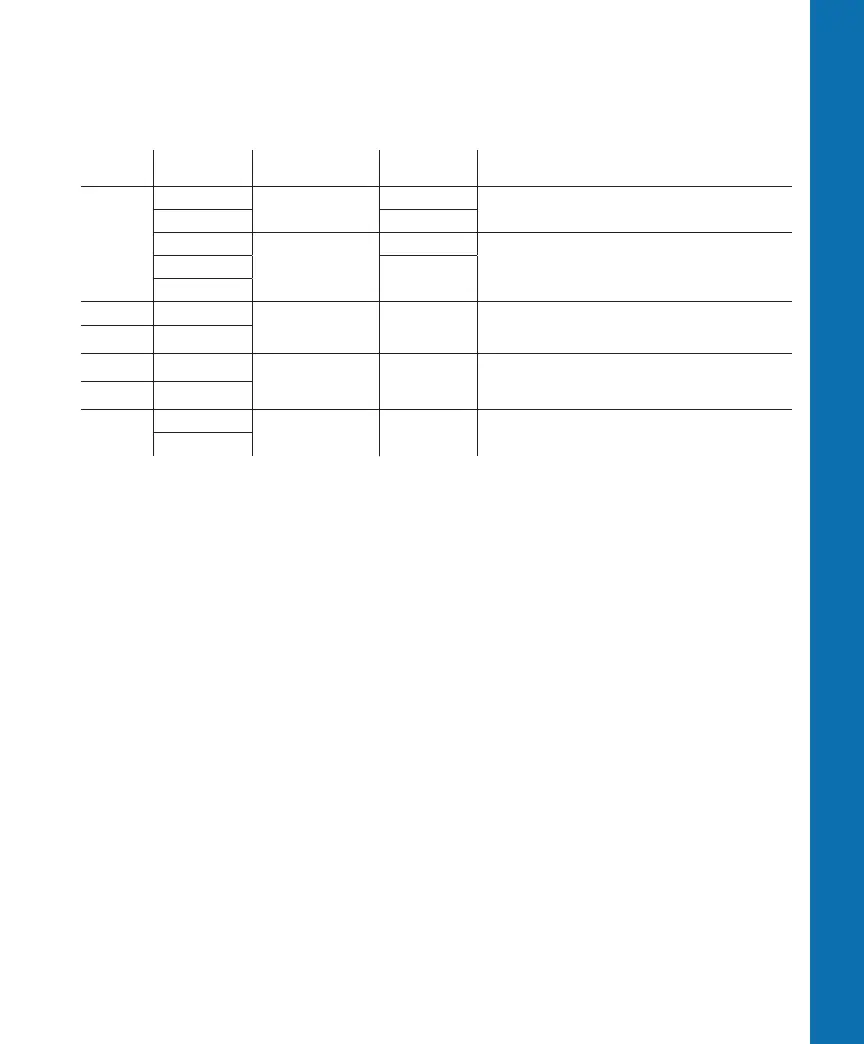

Manual Bearing Adjustment Procedure (reference TMC RP618)

Axle type

Axle Spindle

Threads per inch

Spindle Nut Type

Final Spindle Nut

Backoff

Jam Nut Torque (ft-lbs)

Steer (front

non-drive)

12

Single nut with cotter pin

1/6 turn

Install cotter pin to lock spindle nut into position (from step 6)

18 1/4 turn

12

Double nut system with

bendable tang washer

or dowel pin and washer

1/3 turn

200-30014

1/2 turn

18

Drive 12

Double nut system

Dowel pin and washer

1/4 turn 300-400

16

12

Double nut system with

bendable tang washer

1/4 turn 200-275

16

Trailer

12 Double nut system with

bendable tang washer

or dowel pin and washer

1/4 turn 200-300

16

Loading...

Loading...