43ConMet

8. Brake and Wheel Installation

Caliper Installation

Reinstall and adjust the brake

pads and brake caliper according

to the brake manufacturer’s

recommended instructions.

Wheel Installation

1. Reinstall the wheels and torque

the wheel bolts in a star pattern

to 450-500 ft-lbs. The last nut

rotation must be with a torque-

controlled device.

2. After the rst 50 to 100 miles,

retorque the wheel nuts to 450-

500 ft-lbs in a star pattern. The

last nut rotation must be with a

torque-controlled device.

Hub Pilot Wheel Mounting

System

The brake drum must be fully seated on the drum

pilot and against the hub face during and after

installation of the wheel(s).

CAUTION

!

If your shop practice requires the use of lubricant

or anticorrosion material to the threads and/or the

drum pilot area, avoid getting lubricant on the at

mating surfaces of the hub, drum, and wheels.

NOTE

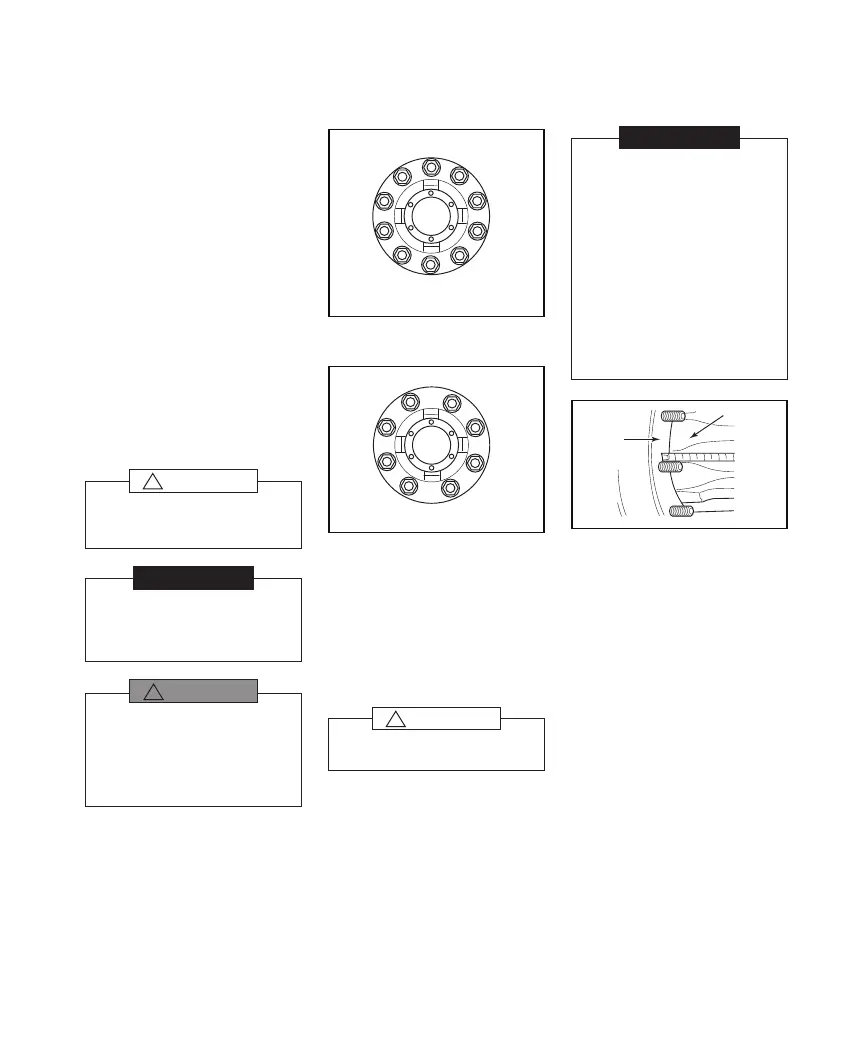

Always snug the top nut rst to fully seat the

brake drum on the drum pilot and against the hub

face. See the adjacent diagram for bolt tightening

sequence, and tighten in order from 1 through 8

or 10, depending on the bolt pattern (see gure

89 and gure 90).

WARNING

!

6

8

10

5

4

9

7

2

10 Stud Tightening Sequence

FIGURE 89

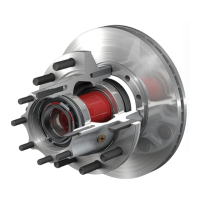

6

8

1

3

5

4

7

2

105757a

8 Stud Tightening Sequence

FIGURE 90

1. Clean all mating surfaces

on the hub, drum and nuts.

Remove loose paint, scale, and

any material building around

the pilots of the drum, hub, and

wheels. Be sure paint is fully

cured on recently refurbished

wheels.

Care should be taken to avoid damaging the hub

or other components.

CAUTION

!

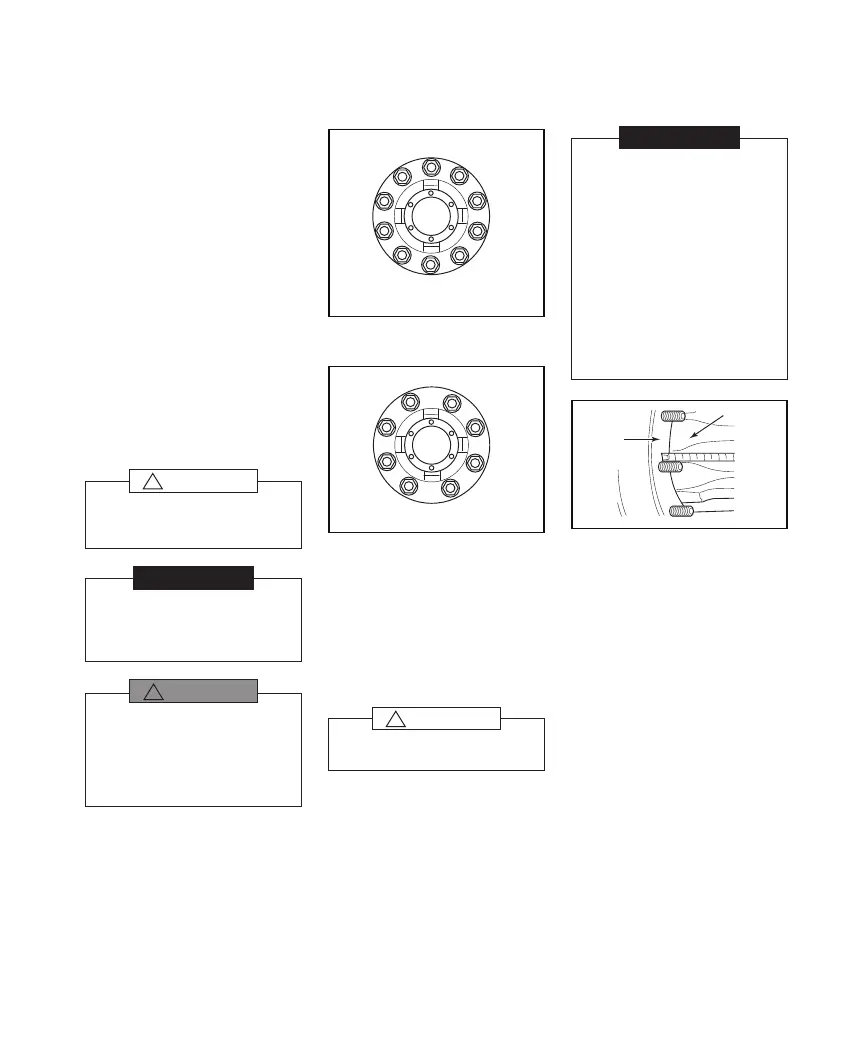

If you plan to replace the brake drum (i.e., cast in

place of CentriFuse®) or wheels (i.e., aluminum

in place of steel), measure stud standout (see

gure 91). In hub piloted mounting systems, the

studs must be long enough for the threads to

be exposed beyond the installed wheel nut. In

the ball seat mounting system, the stud length

beyond the brake drum should be from 1.31-1.44"

as measured from the brake drum to the end of

the stud. Call ConMet at 1-800-547-9473 for the

correct stud part number for your application.

If you plan to replace the brake drum, verify the

new drum has the same drum pilot diameter as

the one that has been removed.

NOTE

1 2 3 4 5

106812a

HUB

BRAKE

DRUM

Measuring Stud Standout

FIGURE 91

2. In environments where a

corrosion inhibitor is benecial,

ConMet recommends the use

of Corrosion Block, a product of

Lear Chemical Research, (905)

564-0018. In severely corrosive

environments, a light coat of

Corrosion Block on the drum

and wheel pilots has proven

benecial.

3. In addition to the above

preparation, apply two drops of

oil to a point between the nuts

and nut ange washer and two

drops to the last two or three

threads at the end of each

stud. Also, lightly lubricate the

pilots on the hub to ease wheel

installation and removal.

Loading...

Loading...