PreSet Plus Wheel Hubs – Recommended Service

33ConMet

6. PreSet Plus Wheel Hubs – Recommended Service

STUD REMOVAL

Observe all warnings and cautions for press

operation provided by the press manufacturer

to avoid serious personal injury and damage to

components.

WARNING

!

1. Place the clean hub in a shop

press with the hub supported

evenly around and adjacent to

the stud being removed.

Failure to adequately support the hub can result in

physical injury and/or damage to the hub.

Some hubs are congured so it is impractical to

have supports to prevent the hub from tipping

when force is applied to the stud. In this case,

support the hub on wood blocks on the oor and

use a heavy hammer to drive the studs out with

several sharp blows. Be careful to avoid damaging

the hub and components, particularly the seal

bore and the ABS tone ring.

WARNING

!

2. Press the stud out of the hub.

STUD REPLACEMENT

On the ball seat wheel mounting system, always

use left-handed threaded studs, which are gold in

color and have an “L” stamped on the end, in the

hub on the driver’s side of the equipment, and use

right-handed threaded studs, which are silver in

color and have an “R” stamped on the end, in the

hub on the passenger’s side of the equipment.

The ConMet part number is located on the head

of the stud. The same part number must be used

for replacement unless changing the drum or

wheel type.

CAUTION

!

1. To install a new stud, support

the hub evenly around and

adjacent to the stud being

installed.

2. Press the new stud all the way

into the hub. Be sure the stud

is fully seated and that the stud

head is not embedded into the

hub.

Excessive force can cause the stud head to be

embedded into the hub, which can create a crack

in the hub, resulting in serious injury and property

damage. If a stud head is Embedded in a hub,

replace the hub.

WARNING

!

HUB, DRUM AND WHEEL

INSPECTION

1. Inspect the drum pilots, wheel

pilots, and mounting face on the

hub for damage. A damaged

drum pilot is usually caused

by improper drum mounting. A

damaged wheel pilot could be

the result of inadequate wheel

nut torque, allowing the wheels

to slip in service. Also, inspect

other surfaces of the hub for

signs of cracks or damage.

2. Inspect the wheels and brake

drum for damage.

Do not repair or recondition wheel-end

components. Replace damaged, worn or out-of-

specication components. Do not mill or machine

any components. Using repaired, reconditioned,

damaged or worn components can cause wheel

end failure, which can result in serious injury and

property damage.

WARNING

!

ABS TONE RING

INSPECTION (AS

APPLICABLE)

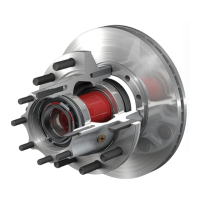

The Anti-Lock Braking System

(ABS) signals acts like any signal

generator where the magnet

passes a coil and generates a

current. On hubs, the toothed ring

passes a sensor and generates

a signal that is sent to the ABS

computer. There are three types of

ABS rings used on ConMet hubs —

machined, stamped steel and bolt

on (see gure 71).

106805b

MACHINED

ABS RING

STAMPED STEEL

ABS RING

BOLT ON

ABS RING

FIGURE 71

If the tone ring is damaged (for

example, if it is dropped, bent,

chipped or dinged), it must be

replaced. For a list of replacement

ABS rings, refer to the Service Parts

List in the back of this section.

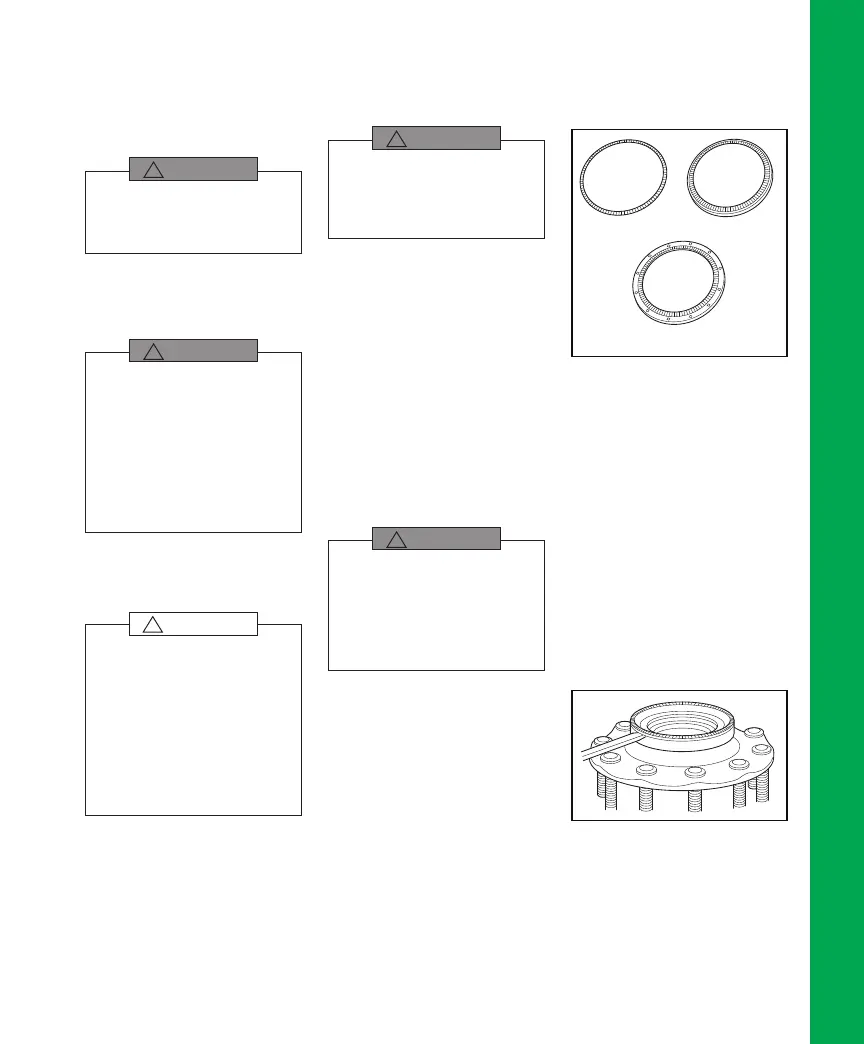

REMOVAL AND

INSTALLATION OF

MACHINED ABS TONE

RING

For a machined metal ring, remove

using a chisel, making sure not to

damage the hub (see gure 72).

Reinstall by heating the ring to

350°F in an oven and installing it on

the hub.

Machined ABS Ring

FIGURE 72

Loading...

Loading...