PreSet Plus Wheel Hubs – Recommended Service

30 ConMet

6. PreSet Plus Wheel Hubs – Recommended Service

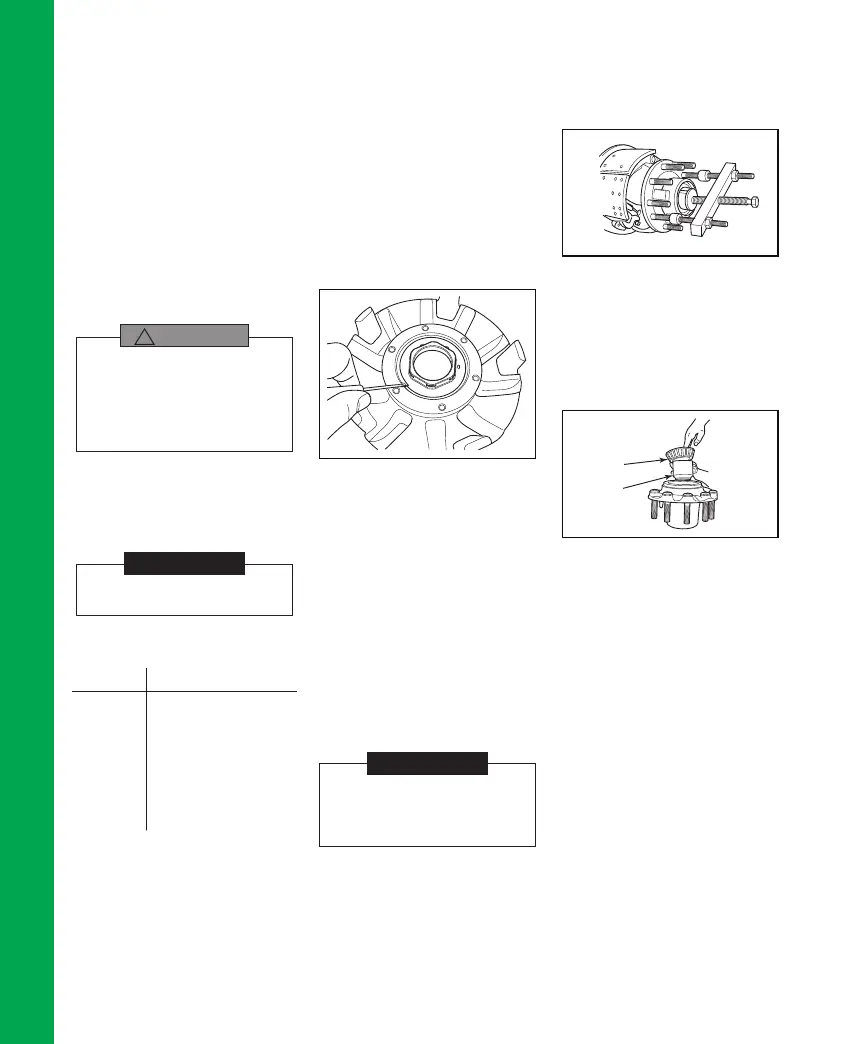

7. Place a container under the

hubcap, or drive axle shaft

for a drive hub, to receive the

draining oil, then remove the

hubcap or drive axle shaft.

Do not reuse the oil. Correctly

dispose of the lubricant.

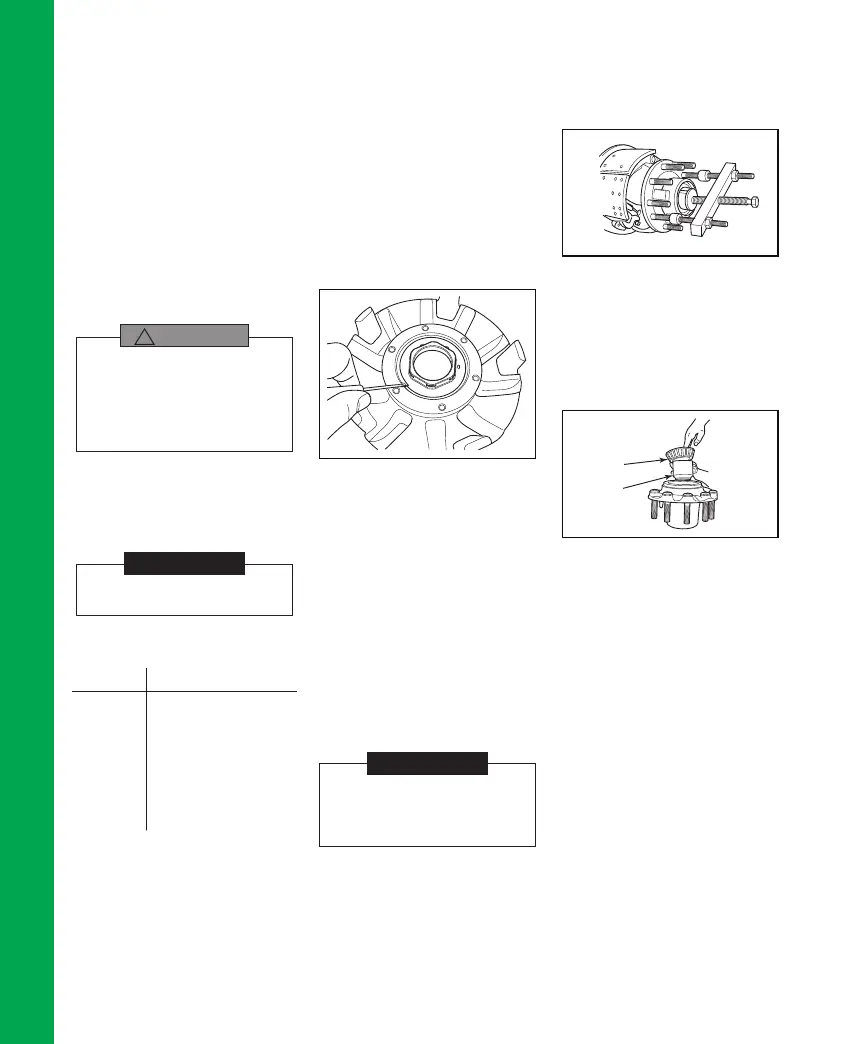

8. Remove the red locking ring.

Use caution not to damage the

locking ring. Do not remove the

spiral snap ring that holds the

spindle nut in the hub.

Do not loosen the axle spindle nuts by either

striking them directly with a hammer, or striking

a drift or chisel placed against them. Damage to

the parts will occur causing possible loss of axle

wheel-end components and serious personal

injury.

WARNING

!

9. Use a breaker bar to loosen the

spindle nut. PreSet Plus spindle

nut installation torque is 300 ft-

lbs for steer hubs and 500 ft-lbs

for drive and trailer hubs.

Use only 6-point forged sockets for installation

and removal of PreSet Plus spindle nuts.

NOTE

Socket Sizes for PreSet Plus

Spindle Nuts

Spindle Nut Socket Size (6 Point)

FF Flat 2"

FF Keyway 2"

FL 2.75"

R 3.75"

TN 3.125"

TP 4"

10. After the spindle nut is initially

loosened with a breaker

bar, loosen the spindle nut

to remove the hub from the

spindle. The internal snap ring

will act as a hub puller and will

aid in removal of the hub from

the spindle. Do not exceed 50

ft-lbs of torque when removing

the hub from the spindle. If the

hub will not come off of the

spindle without exceeding this

torque value, remove the spiral

snap ring (see gure 65) and

the spindle nut assembly and

use a conventional hub puller

to remove the hub from the

spindle.

106871b

Spiral Snap Ring Removal

FIGURE 65

11. Slide the hub off the spindle.

Remove and save the outer

bearing cone. Be careful when

you remove the hub that you do

not damage the outer bearing

by dropping it on the oor.

- If the hub is difcult to remove

because the seal is stuck on

the spindle, use a mechanical

puller to remove the hub (see

gure 66).

- If part of the seal remains on

the spindle, carefully remove

the part of the seal that

remains on the spindle.

This can be done by striking the remaining portion

of the seal with the round end of a ball-peen

hammer. Use caution not to damage the seal

journal on the spindle.

NOTE

105740a

FIGURE 66

12. Place the hub on its outboard

end and remove the seal.

Retain the seal if it needs

to be returned for warranty

consideration.

13. Remove the inner bearing cone

and spacer (see gure 67).

106804c

INNER

BEARING

CONE

SPACER

Hub Disassembly

FIGURE 67

Loading...

Loading...