45ConMet

8. Brake and Wheel Installation (continued)

Table A: Single Aluminum Wheel

Applications

Aluminum Wheels ALCOA Cap Nut No.

3/4-16" Threaded

Studs

5995R and 5995 L or

5554R and 5554L,

depending on

stud length

Table B: Single Steel Wheel

Applications

Steel Wheels BATCO Cap Nut No.

3/4-16" Threaded

Studs

13-3013R and

13-3013L

2. When installing the inner wheel

and tire assembly, verify the

inner nuts being used are

suitable for the application:

aluminum wheels, steel wheels,

brake drum thickness, etc.

Inner cap nuts must be deep enough to ensure the

stud will not bottom inside the nut and must be of

a conguration approved by wheel manufacturer.

CAUTION

!

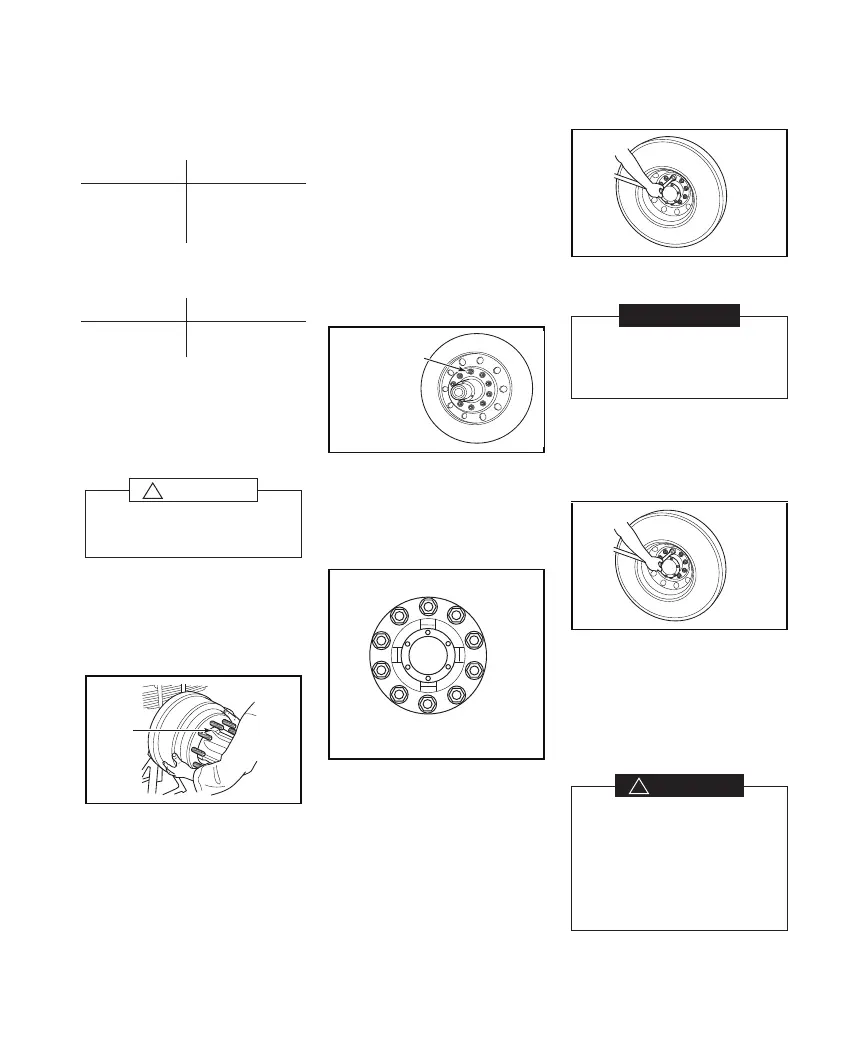

3. Rotate the hub to bring a drum

pilot to the top (12 o’clock)

position (see gure 95).

Position the inner wheel and

tire assembly over the studs

against the drum.

106814a

DRUM

PILOT

Rotating the Drum Pilot to 12 o'Clock

FIGURE 95

4. Beginning in the 12 o’clock

position, install the inner cap

nuts by hand to ensure they

are not cross-threaded. Do not

tighten any nuts at this time.

5. Apply sufcient torque (about

50 ft-lbs) to the inner top cap

nut to draw the brake drum up

on the drum pilot and against

the hub and seat the ball seat

of the nut into the ball socket of

the wheel (see gure 96).

106815a

INNER CAP NUT AT

12 O’CLOCK POSITION

Tightening the Inner Cap Nuts

FIGURE 96

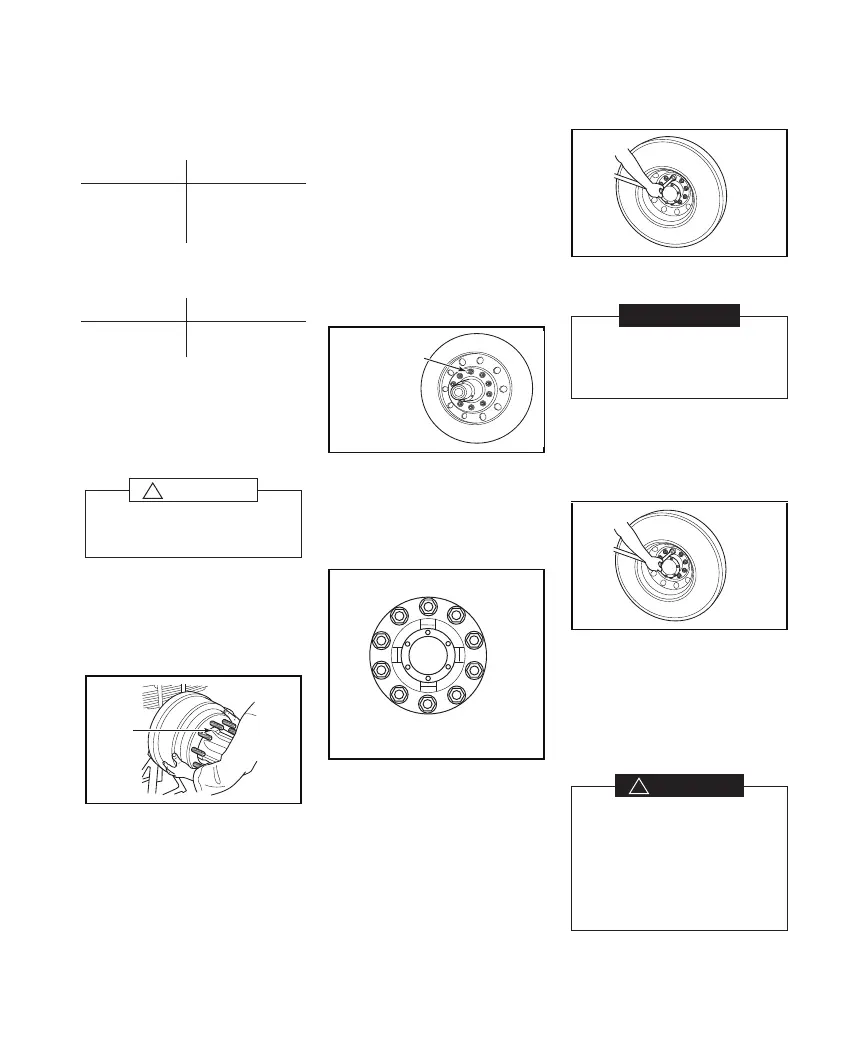

6. To properly center the wheel,

snug the remaining wheel nuts.

Verify the drum is in place over

the drum pilots (see gure 97).

6

8

10

5

4

9

7

2

10 Stud Tightening Sequence

FIGURE 97

7. Starting with the top nut rst

and using a staggered pattern,

torque the inner wheel nuts in

stages to 450-500 ft-lbs (see

gure 98). The last nut rotation

must be with a calibrated

torquing device.

106824b

Torquing the Innner Wheel Nuts

FIGURE 98

Use the appropriate nuts with the above

technique to install the front and outer dual

wheels. Follow your shop practice to locate the

valve stems.

NOTE

8. Install the outer wheel and

nuts and tighten to 450-500

ft-lbs (see gure 99). The last

nut rotation must be with a

calibrated torque device.

106824b

Torquing the Outer Wheel Nuts

FIGURE 99

9. Inspect the brake and wheel

installation by checking the

seating of the wheel(s) and

drum at the pilots and by

turning the wheel(s) and check

for any irregularity.

Excessive or inadequate wheel nut torque can

cause a failure of the wheel mounting system and

a wheel separation resulting in severe personal

injury or death and property damage. Always use

a device that measures the torque being applied.

After the rst 50-100 miles, retorque all the

nuts to 450-500 ft-lbs. Loosen the outer nuts to

retorque the inner nuts.

DANGER

!

Loading...

Loading...