*

96 M’Ax User Guide

Issue Number: 4

D.5 Gain sequencing

The Drive has three sets of PID gains and the SLM has a corresponding

set of PID buffers. Each PID-gains set in the Drive can be set up for a

different operating condition (e.g. a particular load and/or position). A

PID buffer in the

SLM can be activated within 1ms of a command being

received.

For example, lower values of PID gains can be used when a resonance

is traversed during acceleration, and the required values for the process

used when the range of operating speeds is reached.

The PID-gains parameters in Menu 0 relate to the parameters in PID

gains 1 (see Figure D-3). Selection among the three sets is made by

3.16 {0.12} Speed-loop gains selector.

Setting up PID gains for gain sequencing

Each PID-gains set is set up individually by following the procedure in

Adjusting the speed-loop gains or Specifying shaft stiffness and load

inertia. To ensure the required PID-gains set is adjusted while following

the procedure, set

3.16 {0.12} Speed-loop gains selector as follows:

Unlock security before adjusting these gains.

The parameters in each PID-gains set are as follows:

PID-gains set 1

3.10 {0.13} Speed-loop proportional gain Kp1

3.11 {0.14} Speed-loop integral gain Ki1

3.12 {0.15} Speed-loop derivative gain Kd1

4.12 {0.16} Current-demand filter 1 cut-off frequency

4.07 {0.18} Symmetrical current limit Kc1

PID-gains set 2

3.13 Speed-loop proportional gain Kp2

3.14 Speed-loop integral gain Ki2

3.15 Speed-loop derivative gain Kd2

4.23 Current-demand filter 2 cut-off frequency

4.24 Symmetrical current limit Kc2

PID-gains set 3

3.60 Speed-loop proportional gain Kp3

3.61 Speed-loop integral gain Ki3

3.62 Speed-loop derivative gain Kd3

4.27 Current-demand filter 3 cut-off frequency

4.28 Symmetrical current limit Kc3

Selection of PID-gains sets and PID buffers

Following power-up, new PID-gain(s) value(s) take

effect only after the motor shaft has passed through the

zero position of the feedback encoder.

When the motor is running or stopped, a PID buffer in the SLM (and the

related PID-gains set in the Drive) can be selected by any of the

following means:

Using the keypad or serial communications to adjust the PID-gains

selector

1. Change the setting of 3.16 {0.12} Speed-loop gains selector as

follows:

2. Set

11.63 SLM buffer update at 1.

3. The newly selected PID buffer takes effect immediately.

Using the keypad or serial communications to select by edge-

triggering

1. Set 3.16 {0.12} Speed-loop gains selector at 0. This allows PID

buffers to be selected by edge-triggering.

2. Refer to the following table and ensure the appropriate parameter is

first set at

0, then set it at 1 in order to select the required PID buffer;

the PID buffer is selected on the rising edge.

3. The newly selected PID buffer takes effect immediately.

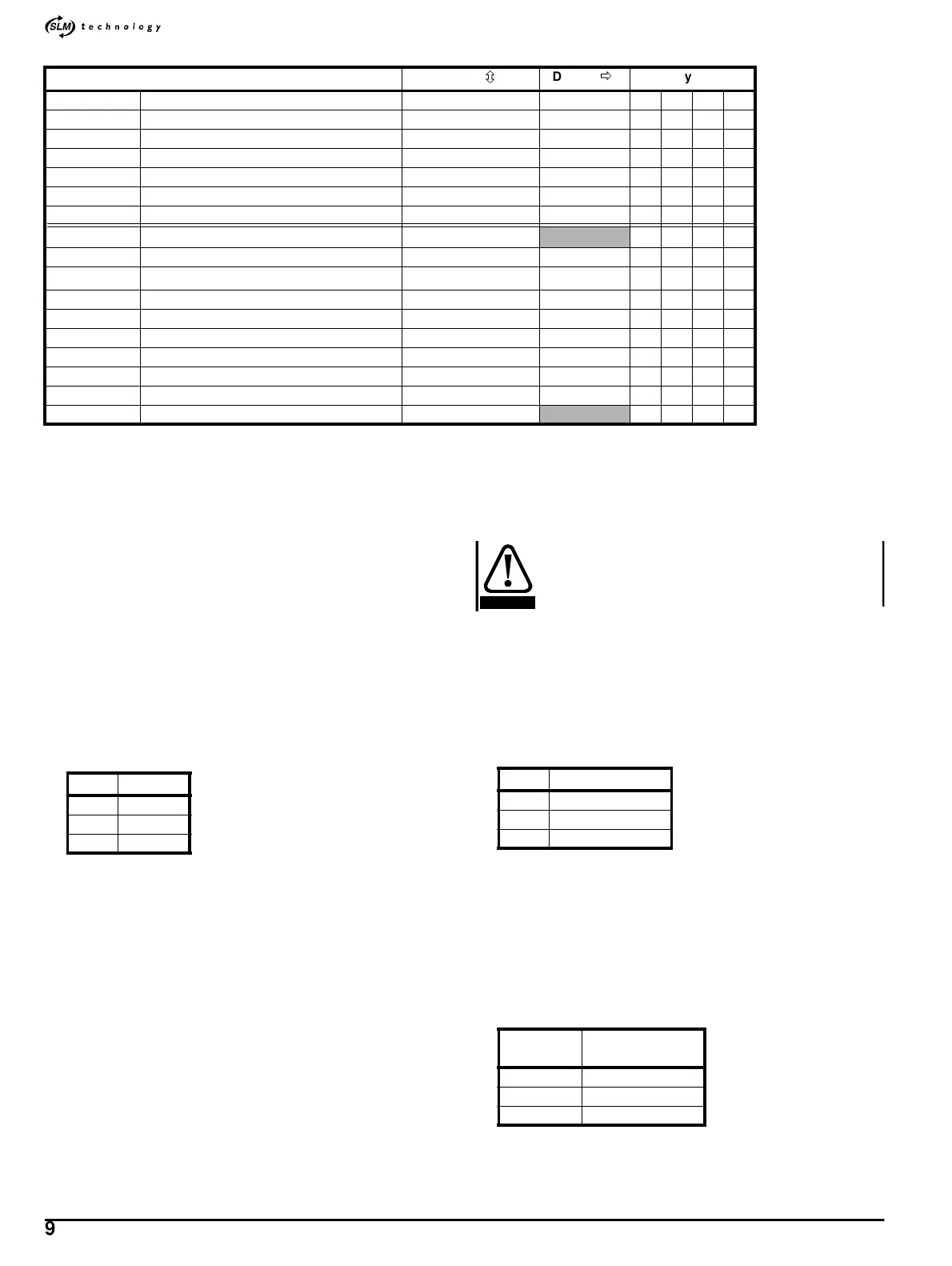

Parameter Range(

ô

)Default(

ð

)Type

3.10 {0.13} Speed-loop proportional gain Kp1 0.0000 ~ 0.3000 0.0100 RW Uni

3.11 {0.14} Speed-loop integral gain Ki1 0.000 ~ 20.000 6.000 RW Uni

3.12 {0.15} Speed-loop derivative gain Kd1 0.0000 ~ 0.1000 0.0000 RW Uni

3.13 Speed-loop proportional gain Kp2 0.0000 ~ 0.3000 0.0100 RW Uni

3.14 Speed-loop integral gain Ki2 0.000 ~ 20.000 6.000 RW Uni

3.15 Speed-loop differential-feedback gain Kd2 0.0000 ~ 0.1000 0.0000 RW Uni

3.16 {0.12} Speed-loop PID gains selector 0 ~ 3 1 RW Uni

3.18 {0.11} Total inertia

0.01 ~ 600.00kgcm

2

RO Uni

3.19 {0.09} Stiffness angle 0 ~ 30.0° 6.0 RW Uni

3.20 {0.10} Load inertia

0.01 ~ 600.00kgcm

2

J

ML

RW Uni

3.57 Speed-loop buffer 1 select 0~1 0 RW Bit

3.58 Speed-loop buffer 2 select 0~1 0 RW Bit

3.59 Speed-loop buffer 3 select 0~1 0 RW Bit

3.60 Speed-loop proportional gain Kp3 0.0000 ~ 0.3000 0.0100 RW Uni

3.61 Speed-loop integral gain Ki3 0.000 ~ 20.000 6.000 RW Uni

3.62 Speed-loop derivative gain Kd3 0.0000 ~ 0.1000 0.0000 RW Uni

3.63 Speed-loop PID buffer in use indicator 0~3

RO Uni

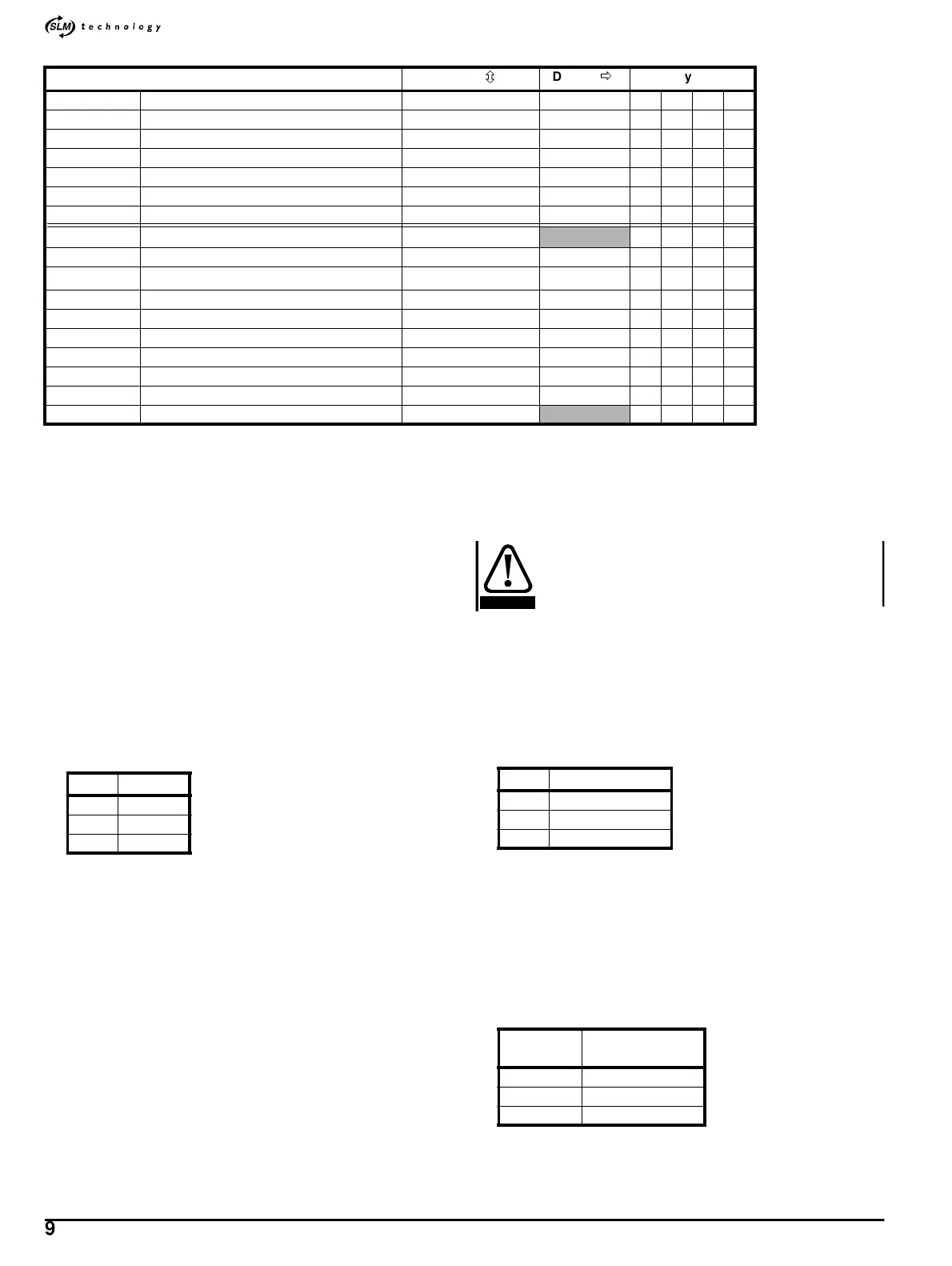

3.16 PID gains

11

22

33

3.16 Select PID buffer...

11

22

33

To select

PID buffer...

Use parameter...

13.57

23.58

33.59

CAUTION

Loading...

Loading...