*

M’Ax User Guide 87

Issue Number: 4

Line loading

The Drive loads the EIA485 serial communications lines as follows:

In accordance with the EIA485 specification, the total load on a line must

not exceed 32 unit-loads.

Each transmitter and receiver of the Drive loads the line by two unit-

loads. This allows up to 16 Drives to be linked without the use of line

repeaters.

If a line repeater is added, a maximum of 15 Drives can be linked direct

to the PLC (ie. before the line repeater).

Routing the serial communications cables

A data communications cable should not run parallel to any power

cables, especially any that connect Drives to motors. If parallel runs are

unavoidable, ensure a minimum spacing of 300mm (12 in) between the

communications cable and the power cable.

Where cables are required to cross, they should be at right-angles to

each other in order to minimize coupling.

The maximum cable length for an EIA485 link is 1200 metres (4000

feet).

Devices must be chain-connected on an EIA485 communications link.

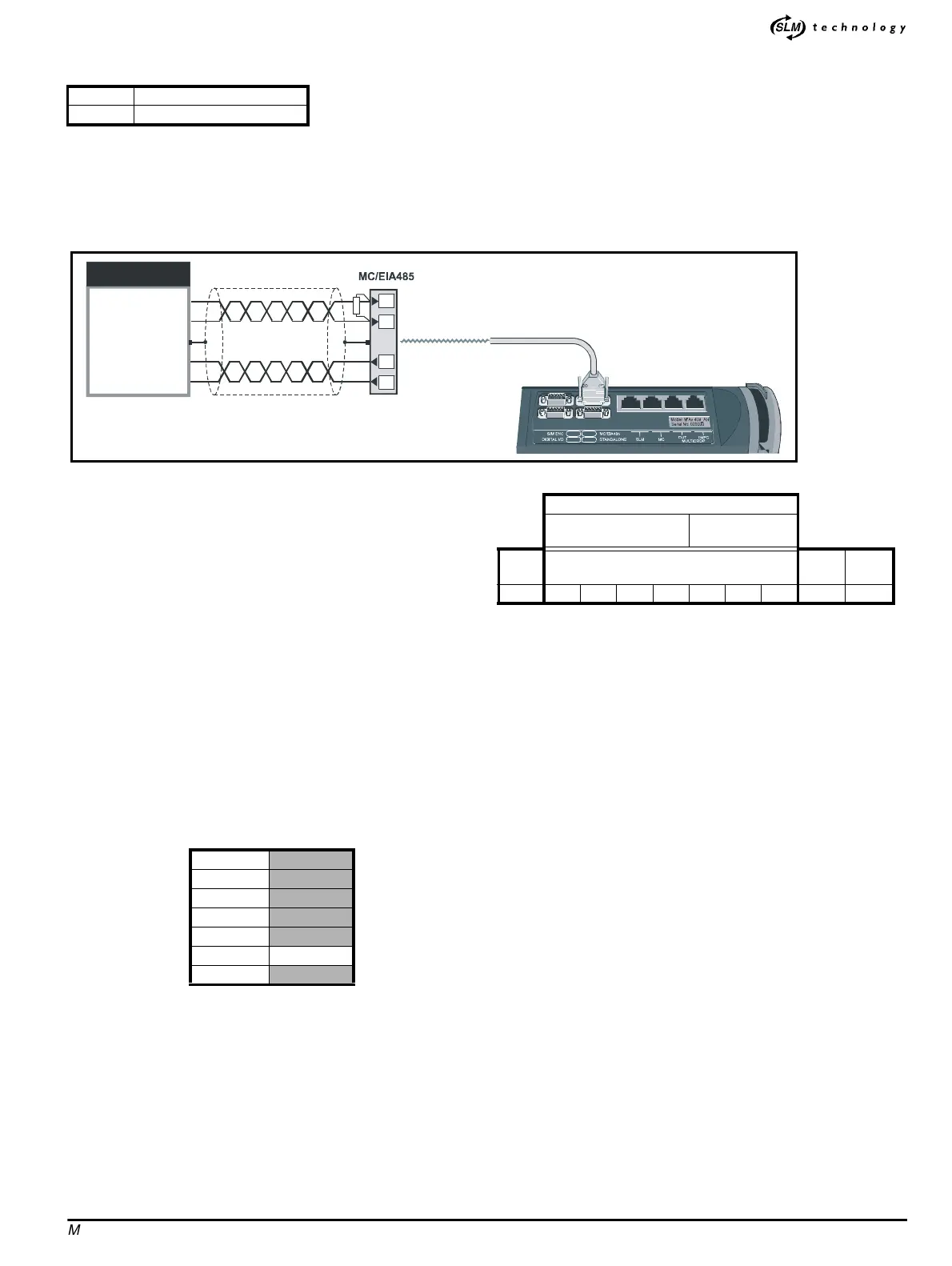

Figure C.1 Connections for an EIA485 4-wire link

Line biasing

Internal 12kΩ bias resistors ensure that logic 1 is detected when the RX

lines are not driven.

Specifying an address

Each device must be programmed by the user to have a two-part

address number in the form

G.U ,whereG is the group number (1 to 9)

and

U is the unit number (1 to 9) in the specified group.

This form of addressing allows the following:

• Anindividualdevicetobeaddressed

• A group of devices to be addressed

• All devices to be addressed

Setting-up procedure

1. Set parameter 0.37 at the required address for the Drive. The value

entered in this parameter must take the form

G.U ,whereG is the

group number (

1 to 9)andU is the unit number (1 to 9)inthe

specified group. The default value is

1.1.Thevalue0 must not be

used.

2. Set parameter

0.36 as follows for the required baud rate:

C.5 Transmitting and receiving data

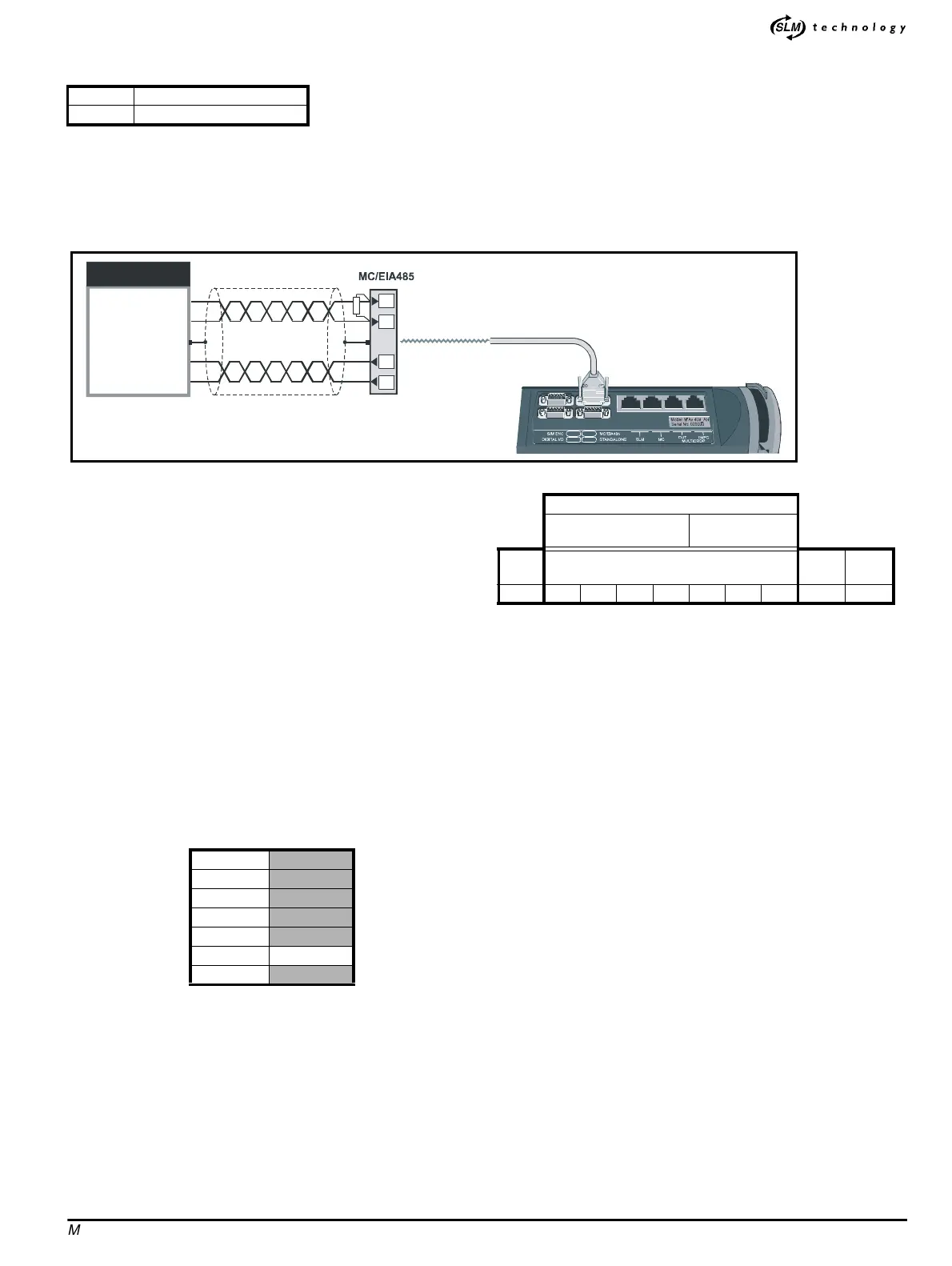

Fundamentals of data transmission

Data is transmitted at a fixed speed (baud rate) in the form of a

character. A character may typically comprise seven or eight bits.

In order for a receiver to recognise valid data, a start bit, an optional

parity bit and a stop bit are transmitted along with the character, forming

a frame, as shown following.

This is known as a 10-bit frame, since 10 bits in total are transmitted.

The format of the frame is often described as follows:

1 start bit, 7 data bits, even parity, 1 stop bit

lsb = Least-significant bit (ie. bit 0)

msb = Most-significant bit (ie. bit 6)

The parity bit is used by the receiver for checking the integrity of the

data.

Typical-message format

A typical message consists of the following:

• Start control-code

•Deviceaddress

• Parameter number

• Parameter value (data)

• End-of-data control code (ie. stop bit)

• Block checksum (BCC)

Message types

Command

Change the value of a parameter

Enquiry

Enquire the value of a parameter

Reply

Contains a parameter value in response to an enquiry

Acknowledge

Message accepted or rejected, or repeat the last command

Acknowledge messages contain only a control code

RX 2 unit-loads (EIA485)

TX 2 unit-loads (EIA485)

13

14

6

7

RX

RX\

TX

TX\

TX

TX\

RX

RX\

0V

EIA485

interface

PLC

300

600

1200

2400

4800

9600 Default

19200

Low-ASCII character-byte

1st hex

character

2nd hex

character

Start

bit

Sevendatabits

Parity

bit

Stop

bit

0 Isb ... ... ... ... ... msb even 1

Loading...

Loading...