20 Unidrive SP Low Voltage DC Installation Guide

www.controltechniques.com Issue Number: 1

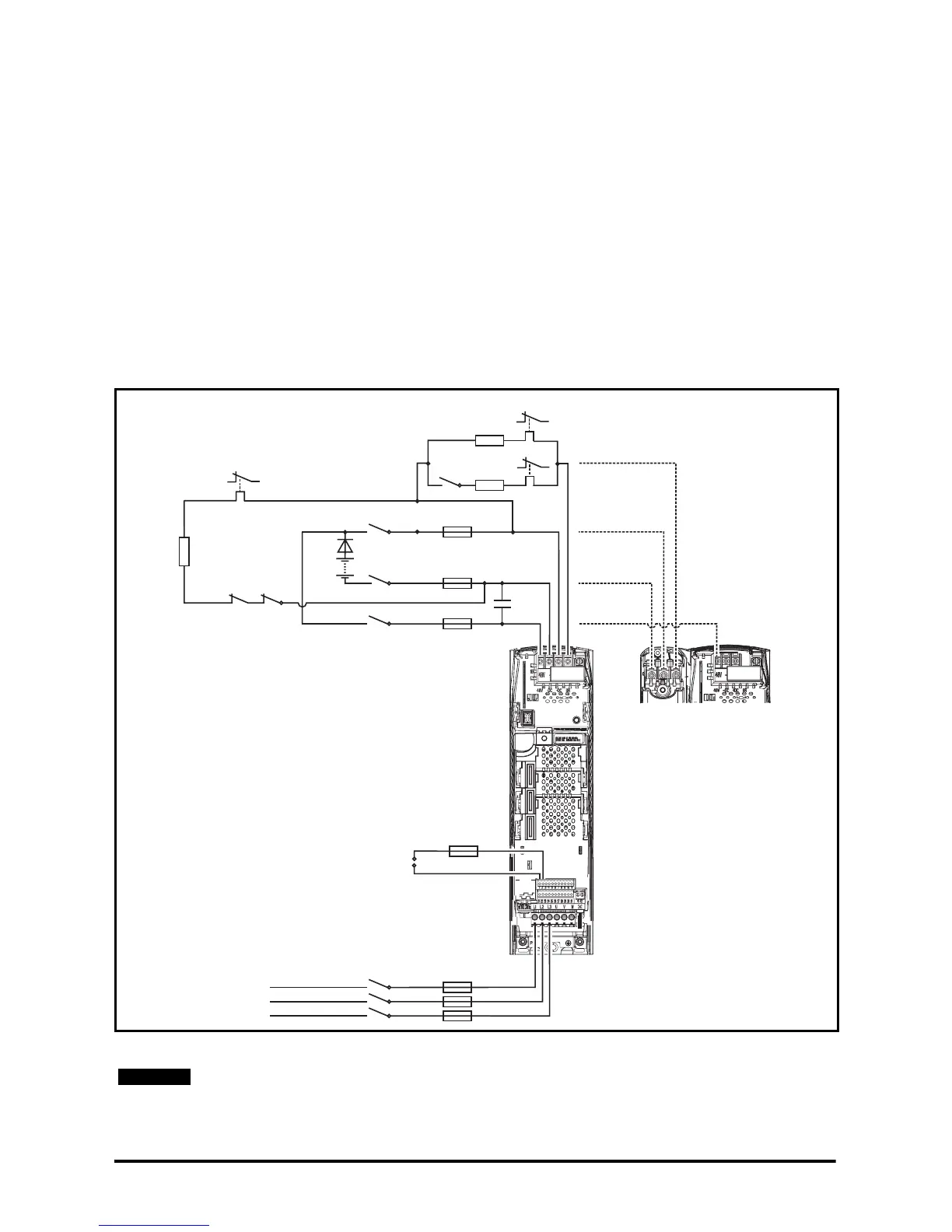

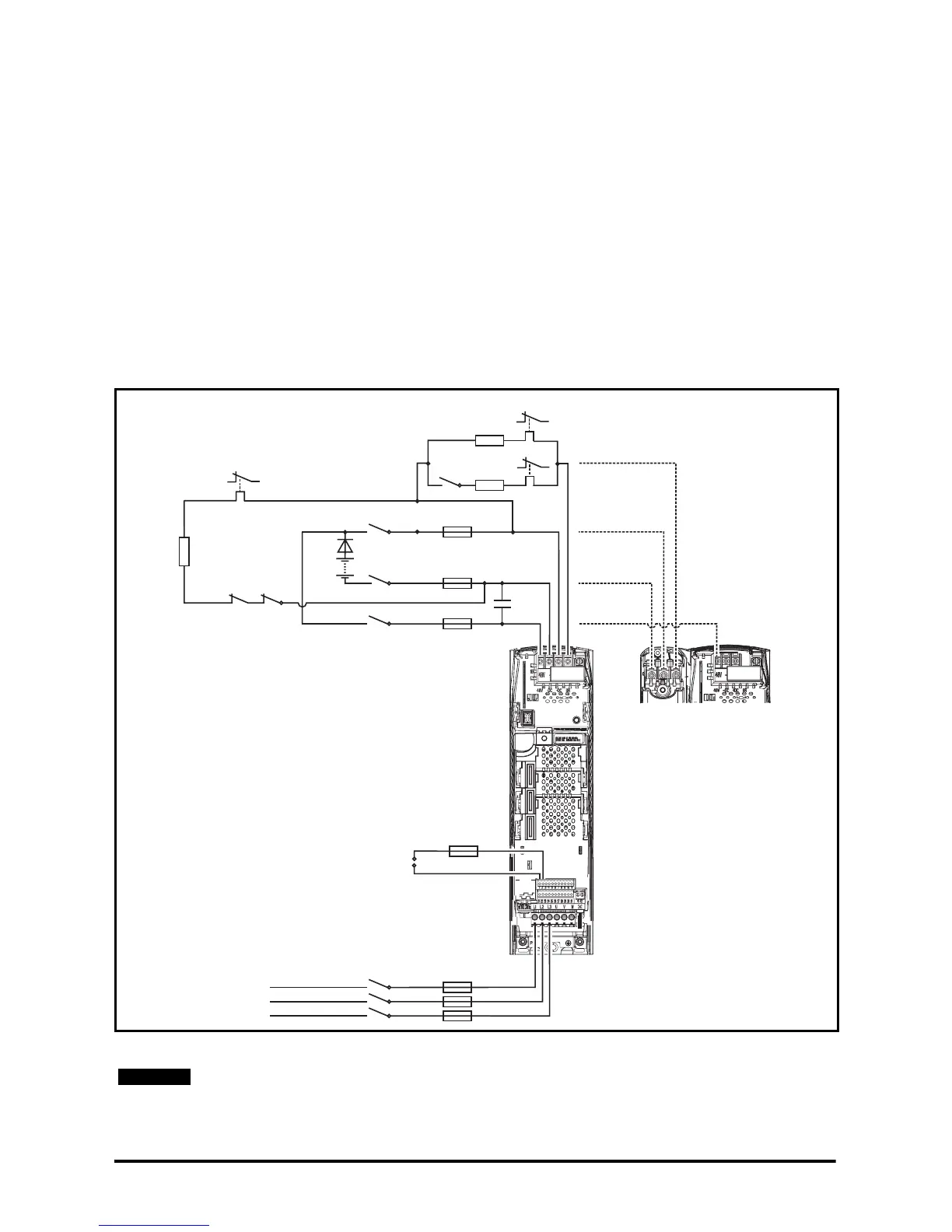

4.6.5 System configuration 2

This configuration is suitable for systems where the drive may be expected to absorb

energy from the load at drive rated current (including overload current if applicable), and

dissipate this energy into a brake resistor. However, further consideration is required

when using a brake resistor in Low Voltage DC mode.

As the DC bus voltage varies the motor power available varies in proportion to the

voltage but the power that may be dissipated in a brake resistor varies with the square

of the voltage. To enable the maximum brake power to match that from the motor in Low

Voltage DC mode, the brake resistor value must be reduced in proportion to the voltage.

The arrangement shown in the circuit below automatically connects the appropriate

brake resistor depending on the supply voltage. Note that the brake resistor thermal

overload devices are also connected to the supply selection interlocks. If either resistor

overheats, then the Low Voltage DC and AC supplies are both tripped off. As shown in

Figure 4-6 Control circuitry for system configuration 2 on page 21

Figure 4-5 System configuration 2 circuit diagram for Unidrive SP size 1 to 3

*C1 is only required with Unidrive SP size 1

See Chapter 5 Component data for details on components.

F2a

F2b

F2c

C1*

Rdis

PS1

D1

K1b K2d

-DC

48V

+DC

48V

DC1/-DC

DC2/+DC

Size 2 and 3

connections

Brake

Brake

F1a

3-phase

AC supply

K1

L1

L2

L3

F3

T2

T1

K2c

K2b

K2a

Aux.1

Ovld.1

R_LVDC

K2f

R_norm

Aux.3

Aux.2

Ovld.3

Ovld.2

Control + 24V

external input

The total brake resistance used in Low Voltage DC mode is the parallel configuration of

R_ LVDC and R_norm.

NOTE

Loading...

Loading...