12

Curtis 1220 Manual, Rev. C

COMMAND DEVICE, cont’d

ALLOWABLE

PARAMETER RANGE DESCRIPTION

Command Analog Left 0 – 5.00 V Denes the command analog wiper voltage required to produce a steer

position command of full left (Steer Command = -100% = Left Stop).

Command Analog Center 0 – 5.00 V Denes the command analog wiper voltage required to produce a steer

position command of center (Steer Command = 0% = 0°).

Command Analog Right

0 – 5.00 V Denes the command analog wiper voltage required to produce a steer

position command of full right (Steer Command = 100% = Right Stop).

Command Analog Fault Min 0 – 5.00 V Sets the minimum threshold for the analog pot input.

If the command analog wiper voltage goes below this threshhold

for 60 ms, a fault is issued.

Command Analog Fault Max

0 – 5.00 V Sets the maximum threshold for the analog pot input.

If the command analog wiper voltage rises above this threshhold

for 60 ms, a fault is issued.

3 — PROGRAMMABLE PARAMETERS: Command Device Parameters

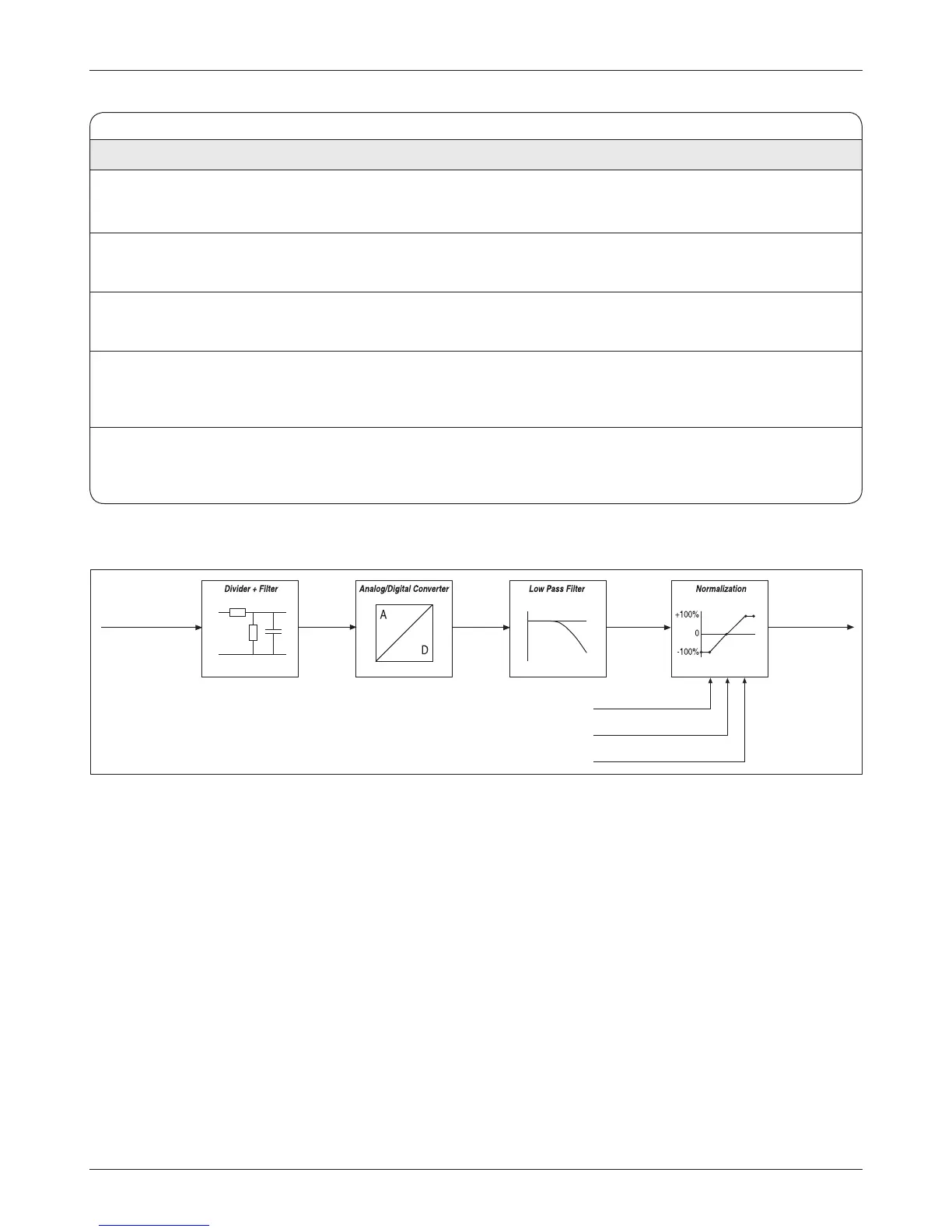

Fig. 4 Command signal ow.

e normalization map takes Command Analog 1 in volts and maps it to Steer

Command in percent. Command Analog Left may be set higher or lower than

Command Analog Right. Command Analog Center must be between Command

Analog Left and Command Analog Right. Assuming Command Analog Left is

less than Command Analog Right, the three points of the normalization map

are dened (from left to right in the diagram above) as:

X = Command Analog Left and Y = -100%

X = Command Analog Center and Y = 0%

X = Command Analog Right and Y = 100%.

Command Analog 1

(pin J1-6)

[3.3V]

[12 bits]

Command Analog Left

Command Analog Center

Command Analog Right

Steer Command

Loading...

Loading...