Return to TOC Curtis 1239E-1269E Manual, os 37.0 RevA – May 2021

2 — INSTALLATION AND WIRING

pg. 7

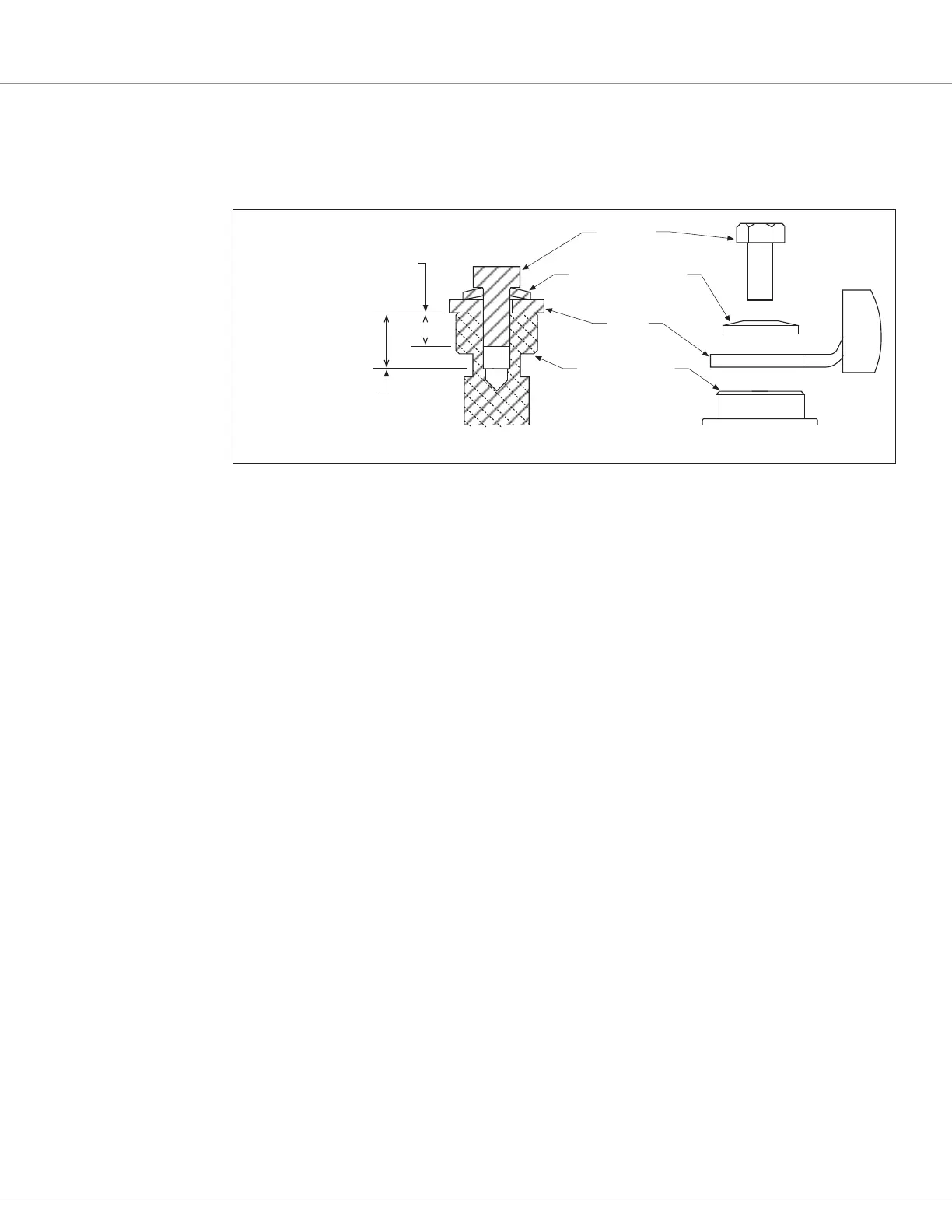

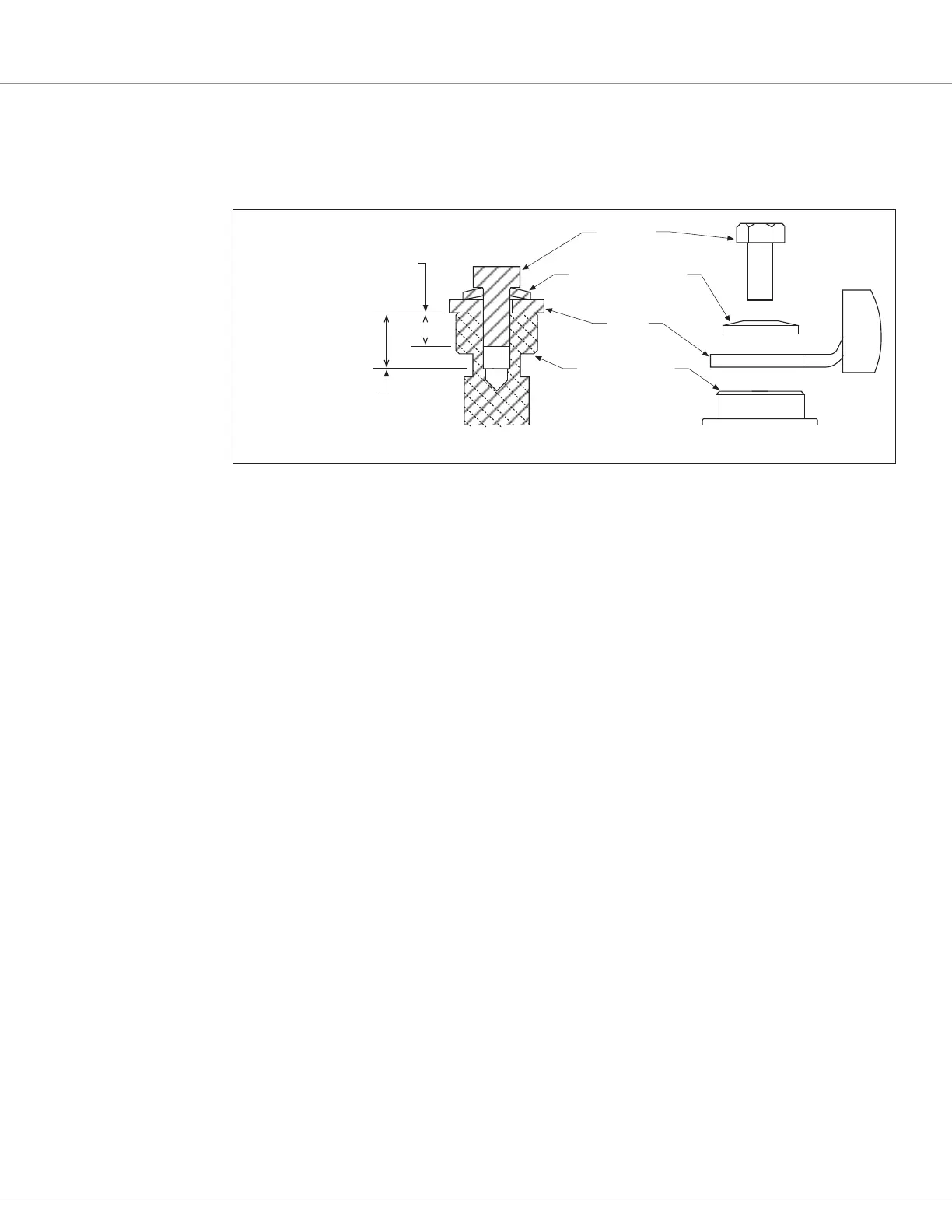

• If two lugs are used on the same terminal, stack them so the lug carrying the least current is

on top.

• Tighten the assembly to 9.6 ± 0.9 N·m (85 ± 8 in-lbs).

High Power Wiring Guidelines

Battery Cables (B+, B–)

ese two cables should be run close to each other between the controller and the battery. Use high

quality copper lugs and observe the recommended torque ratings. For best noise immunity the cables

should not run across the center section of the controller. With multiple high current controllers,

use a star ground from the battery B– terminal.

Motor Wiring (U, V, W)

e three phase wires should be close to the same length and bundled together as they run between

the controller and the motor. e cable lengths should be kept as short as possible. Use high quality

copper lugs and observe the recommended torque ratings.

For optimum noise immunity, the motor cables should not run across the center section of the

controller. In applications that seek the lowest possible emissions, a shield can be placed around

the bundled motor cables and connected to the B– terminal at the controller. Typical installations

will readily pass the emissions standards without a shield. Low current signal wires should not be

run parallel to the motor cables. When necessary they should cross the motor cables at a right angle

to minimize noise coupling. Refer to Appendix A for further information about Electromagnetic

Compatibility (EMC).

M8 BOLT

SAFETY WASHER

LUG

M8 TERMINAL

SECTION VIEW EXPLODED VIEW

7.5 mm MIN DEPTH

13.75 mm

MAX DEPTH

Loading...

Loading...