ENGLISH

39

Failure to respect the above equation may lead to malfunctions of the system or to premature breakage of the diaphragm inside

the expansion vessel.

Considering the expansion vessel capacity of only 1 litres, any operation to check the air pressure must be performed by connecting

the pressure gauge very rapidly: on small volumes the loss of even a limited quantity of air can cause an appreciable drop in

pressure. The quality of the expansion vessel ensures the maintenance of the set air pressure value, proceed to check it only at

calibration or if you are sure of a malfunction.

Any operation to check and/or reset the air pressure must be performed with the delivery system not under pressure: disconnect

the pump from the power supply and open the utility nearest to the pump, keeping it open until it no longer gives any water.

The special structure of the expansion vessel ensures its quantity and duration over time, especially of the diaphragm which is

typically the component subject to wear for items of this type. However, in the case of breakage, the entire expansion vessel must

be replaced and exclusively by authorised personnel.

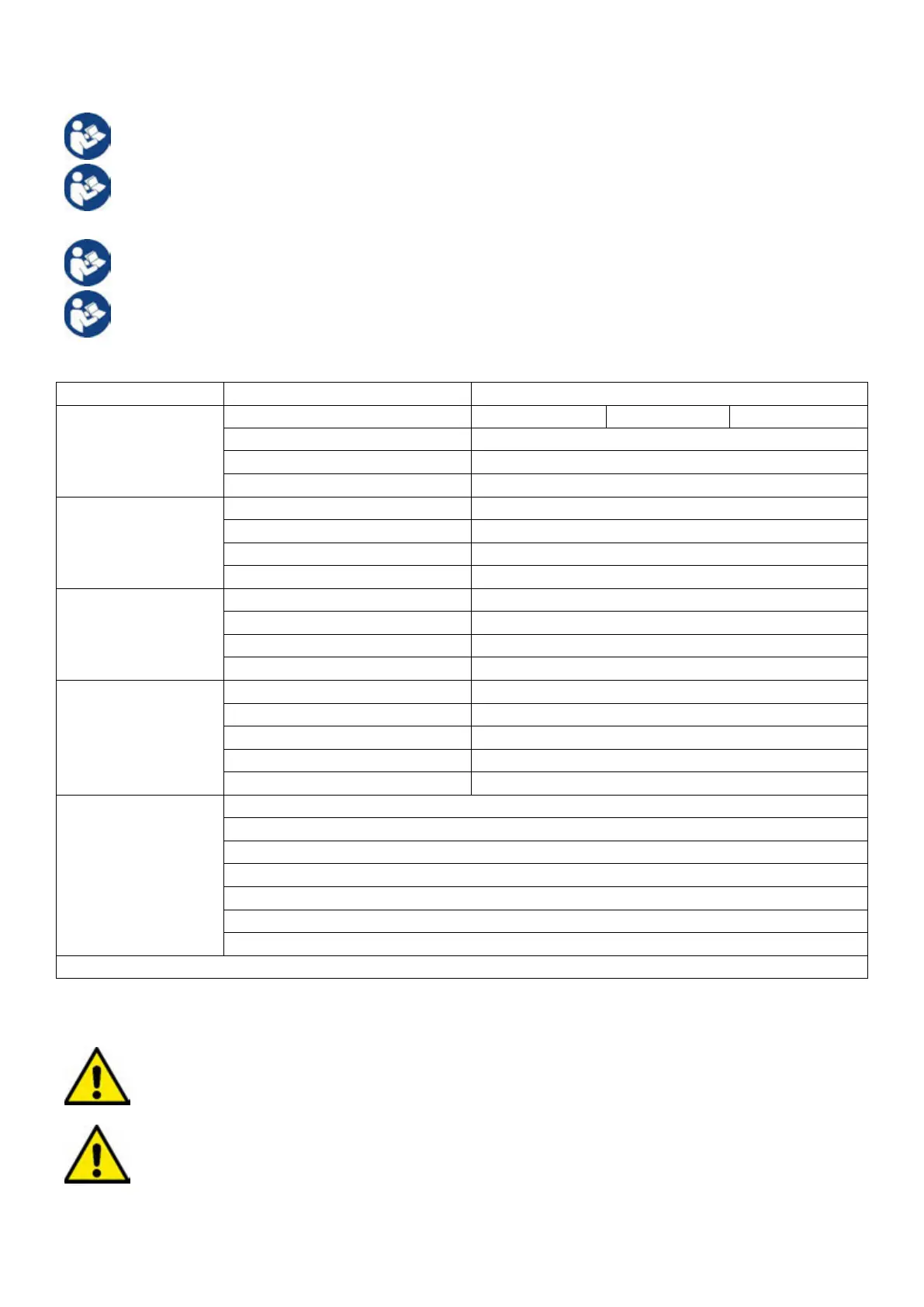

1.4 Technical characteristics

ELECTRIC

POWER SUPPLY

STRUCTURAL

CHARACTERISTICS

445x262x242 mm without feet support

Empty weight (excluding packaging)

HYDRAULIC

PERFORMANCE

WORKING

CONDITIONS

Max environment temperature

Environment temperature of storage

Difference Ambient T. - Liquid T.

FUNCTIONALITY

AND PROTECTIONS

Protection against dry running

Motor overload protection

Protection against abnormal supply voltages

Protection against excess temperature

*: refer to the technical plate on the pump

Tabel 1

2. INSTALLATION

The system is designed for indoor use: do not install the system outdoors and/or directly exposed to atmospheric agents.

The system is designed to be able to work in environments where the temperature remains between 1°C and 50°C (on condition

that the electric power supply is ensured: see par. 5.6.8 “anti-freeze function”). Esybox mini operates correctly with a difference

between ambient and liquid temperatures of no more than 30°C (with the ambient temperature higher than the liquid

temperature). Besides this temperature difference, the humidity limit must not exceed 50%, otherwise there is a risk of

condensation forming, which can cause irreparable damage to the electronic board.

Loading...

Loading...