7

20-06-2023

50400 >

In the event of new product developments, Dancutter reserves the right to change the technical description without advance notice.

Authorised Representative in the United Kingdom: Mini-Cam Limited Unit 33, Ravenscraig Road, Little Hulton, Salford, M38 9PU.

© Copyright 2021 Dancutter A/S. Dancutter A/S is a Halma Company. Dancutter A/S, Livøvej 1 A, DK-8800 Viborg, +45 9651 2150, info@dancutter.dk, dancutter.com

5.1 Checklist

CAMERA CLEANER

1Cleanthecamerausingeitherpureairorwasheruid

w/alcohol.Itisimportantthatwhateveruidisusedcan

evaporate from the camera lens.

2 When adding liquid to the tank, the system/tank

must be de-pressurised.

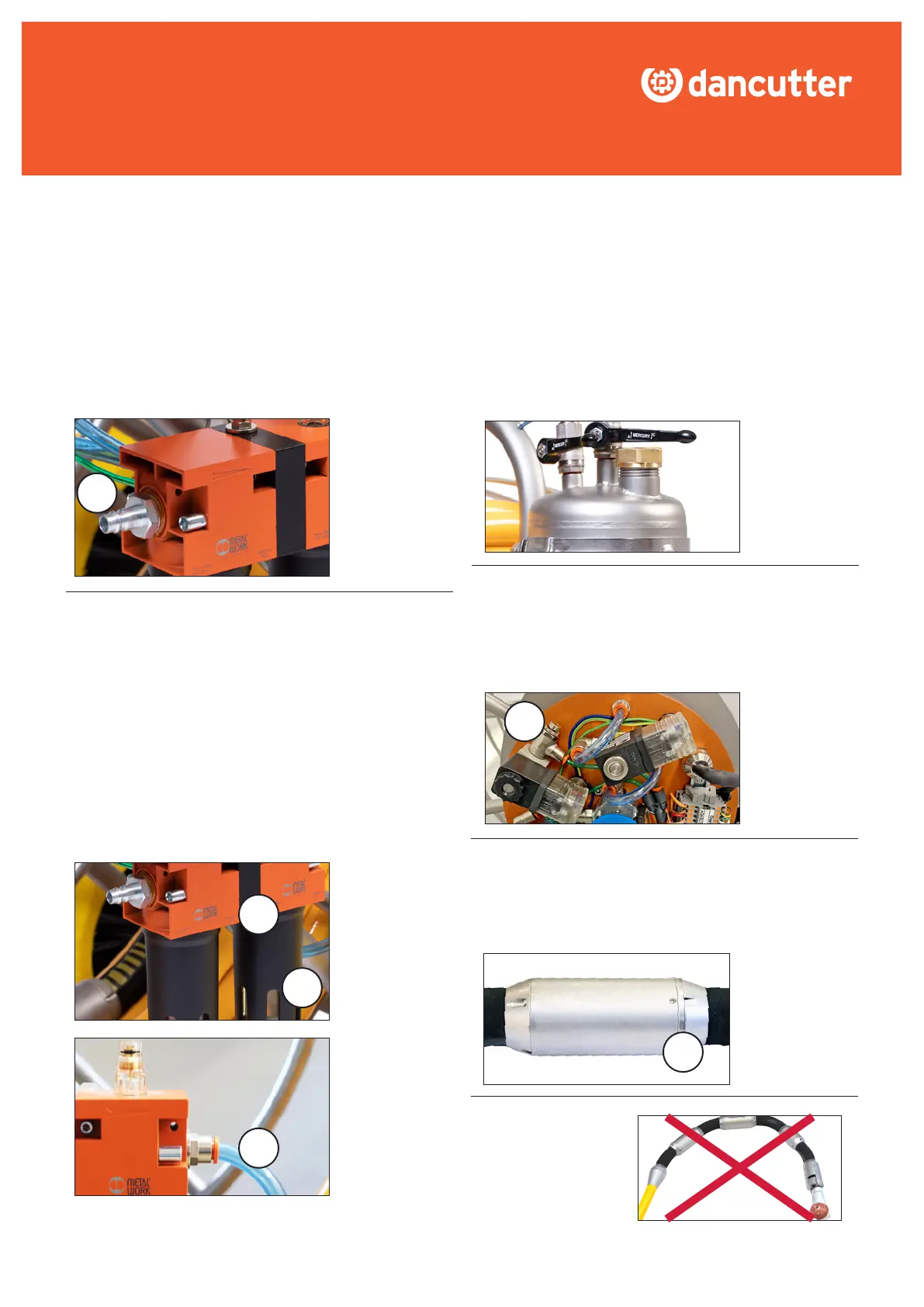

AIR

1 Connect an air supply to the air-processing system - 10 bar

and 650 l/min.

2 A refrigeration dryer must be used with the compressor.

3 Maximum moisture content per m3 of supply air: 20 g/m

3

.

OIL

1 Add pneumatic oil.

2 Check that the oil is clean and that its colour is clear.

Change the oil if it becomes cloudy.

3 If the system has to be laid down during transport, unscrew

the oil-lubricator glass to prevent oil from entering the

cleansing tank.

4 Adjust the adjustment screw once the air sander has been

started. One drop of oil should come out every 8–10 sec.

5 Once the sander has started, it should be possible to see an

oillmowintothe10mmhose.

RAISING/LOWERING THE ARM

1 It is possible to regulate the speed of the arm by rotating the

needle valve; the adjustment works only in the ‘UP’ position.

The arm will lower under its own power. Adjust the arm so

that it rises a bit slower than it falls.

FORWARD/BACK DRIVE

1 Use the forward/back drive only when cutting.

2 The forward/back drive must ALWAYS be retracted to a

closed position during transport, in a tube and outside a

tube.

CUTTER

1 Do NOT bend

the cutter more than 80°.

1

1

1

3

2

5

Loading...

Loading...