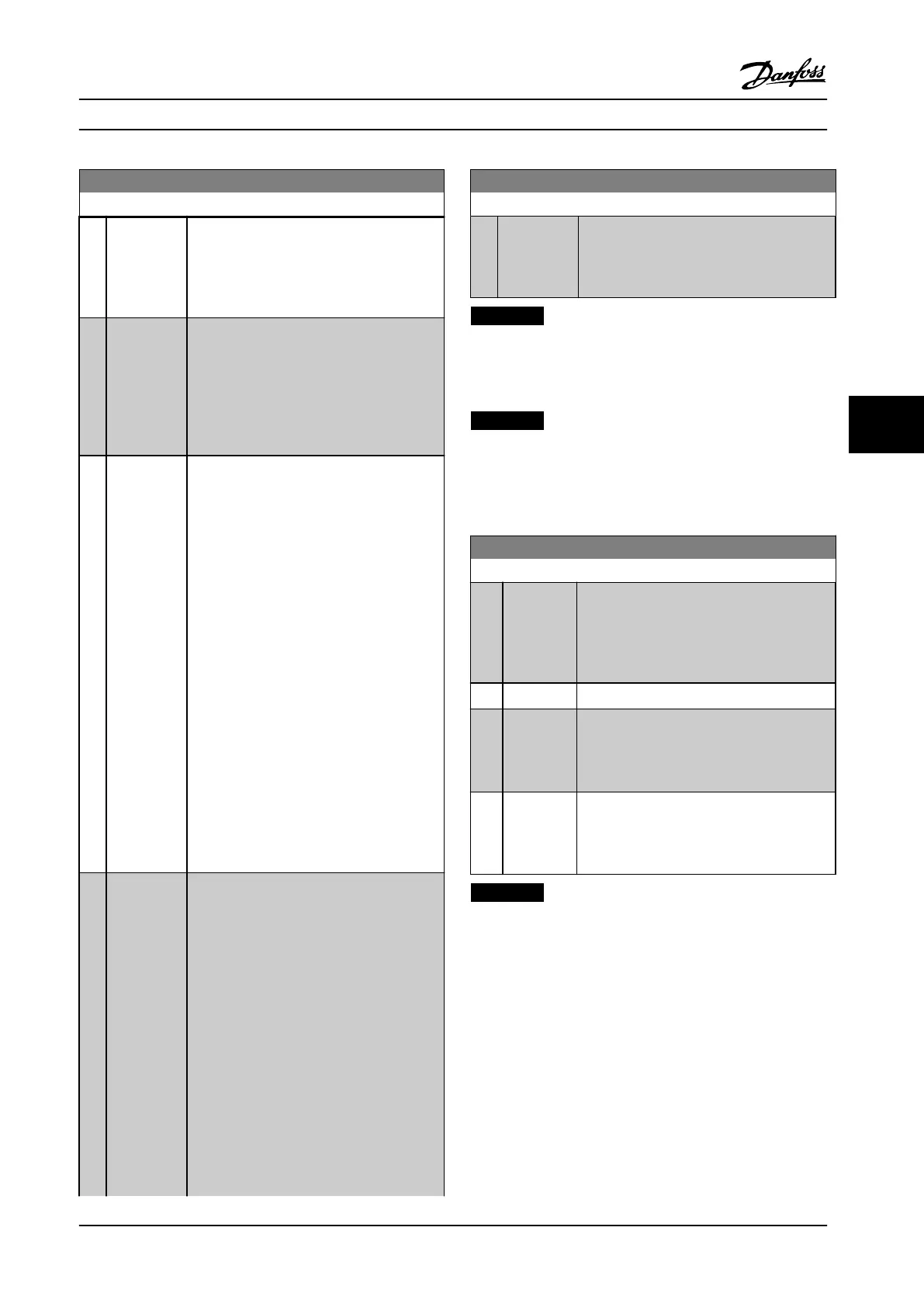

1-03 Torque Characteristics

Option: Function:

[0] Compressor

torque

Compressor [0]: For speed control of screw

and scroll compressors. Provides a voltage

which is optimized for a constant torque load

characteristic of the motor in the entire range

down to 10 Hz.

[1] Variable

torque

Variable Torque [1]: For speed control of

centrifugal pumps and fans. Also to be used

when controlling more than one motor from

the same (e.g., multiple condenser fans or

cooling tower fans). Provides a voltage which

is optimized for a squared torque load

characteristic of the motor.

[2] Auto Energy

Optim. CT

Auto Energy Optimization Compressor [2]: For

optimum energy ecient speed control of

screw and scroll compressors. Provides a

voltage that is optimized for a constant

torque load characteristic of the motor in the

entire range down to 15 Hz. In addition, the

AEO feature will adapt the voltage exactly to

the current load situation, thereby reducing

energy consumption and audible noise from

the motor. To obtain optimal performance,

the motor power factor cos phi must be set

correctly. This value is set in

parameter 14-43 Motor Cos-Phi. The parameter

has a default value which is automatically

adjusted when the motor data is

programmed. These settings will typically

ensure optimum motor voltage but if the

motor power factor cos phi requires tuning,

an AMA function can be carried out using

parameter 1-29 Automatic Motor Adaptation

(AMA). It is very rarely necessary to adjust the

motor power factor parameter manually.

[3]

*

Auto Energy

Optim. VT

Auto Energy Optimization VT [3]: For optimum

energy ecient speed control of centrifugal

pumps and fans. Provides a voltage which is

optimized for a squared torque load charac-

teristic of the motor but in addition the AEO

feature will adapt the voltage exactly to the

current load situation, thereby reducing

energy consumption and audible noise from

the motor. To obtain optimal performance,

the motor power factor cos phi must be set

correctly. This value is set in

parameter 14-43 Motor Cos-Phi. The parameter

has a default value and is automatically

adjusted when the motor data is

programmed. These settings will typically

ensure optimum motor voltage but if the

motor power factor cos phi requires tuning,

1-03 Torque Characteristics

Option: Function:

an AMA function can be carried out using

parameter 1-29 Automatic Motor Adaptation

(AMA). It is very rarely necessary to adjust the

motor power factor parameter manually.

NOTICE!

Parameter 1-03 Torque Characteristics will not have eect

when parameter 1-10 Motor Construction = [1] PM, non-

salient SPM.

NOTICE!

For pumps or fan applications where the viscosity or

density can vary signicantly or where excessive ow,

e.g., due to pipe breakage can occur, it is recommended

to select Auto Energy Optim. CT.

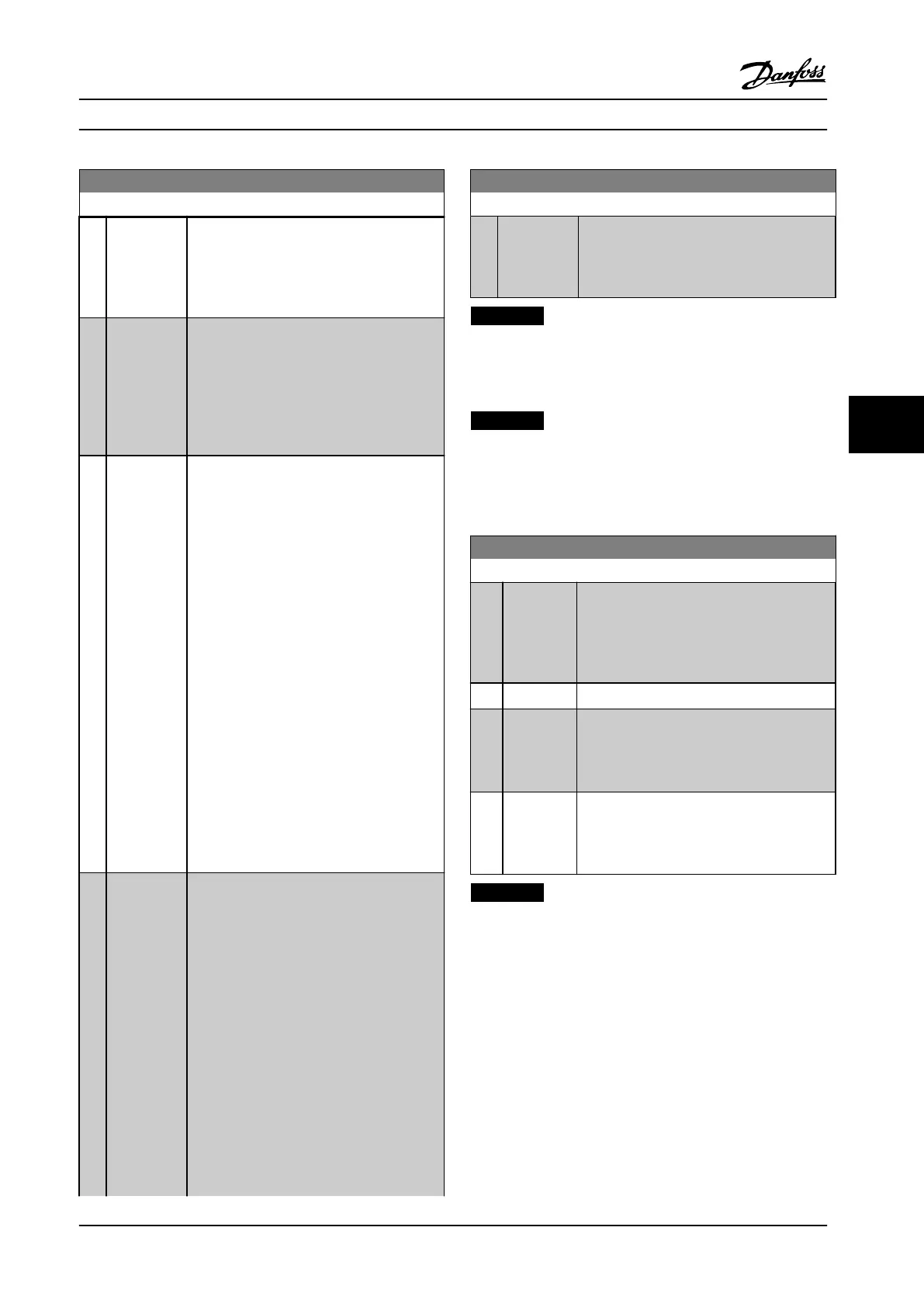

1-29 Automatic Motor Adaptation (AMA)

Option: Function:

The AMA function optimizes dynamic motor

performance by automatically optimizing the

advanced motor parameter 1-30 Stator

Resistance (Rs) to parameter 1-35 Main

Reactance (Xh)) while the motor is stationary.

[0] * O No function

[1] Enable

complete

AMA

Performs AMA of the stator resistance R

S

, the

rotor resistance R

r

, the stator leakage

reactance X

1

, the rotor leakage reactance X

2

and the main reactance X

h

.

[2] Enable

reduced

AMA

Performs a reduced AMA of the stator

resistance R

s

in the system only. Select this

option if an LC lter is used between the

adjustable frequency drive and the motor.

NOTICE!

Parameter 1-29 Automatic Motor Adaptation (AMA) will

not have eect when parameter 1-10 Motor Construction

= [1] PM, non-salient SPM.

Activate the AMA function by pressing [Hand on] after

selecting [1] or [2]. See also the item Automatic Motor

Adaptation in the Design Guide. After a normal sequence,

the display will read: “Press [OK] to

nish AMA”. After

pressing the [OK] key, the adjustable frequency drive is

ready for operation.

How to Program

Instruction Manual

MG11F522 Danfoss A/S © 08/2014 All rights reserved. 87

6 6

Loading...

Loading...