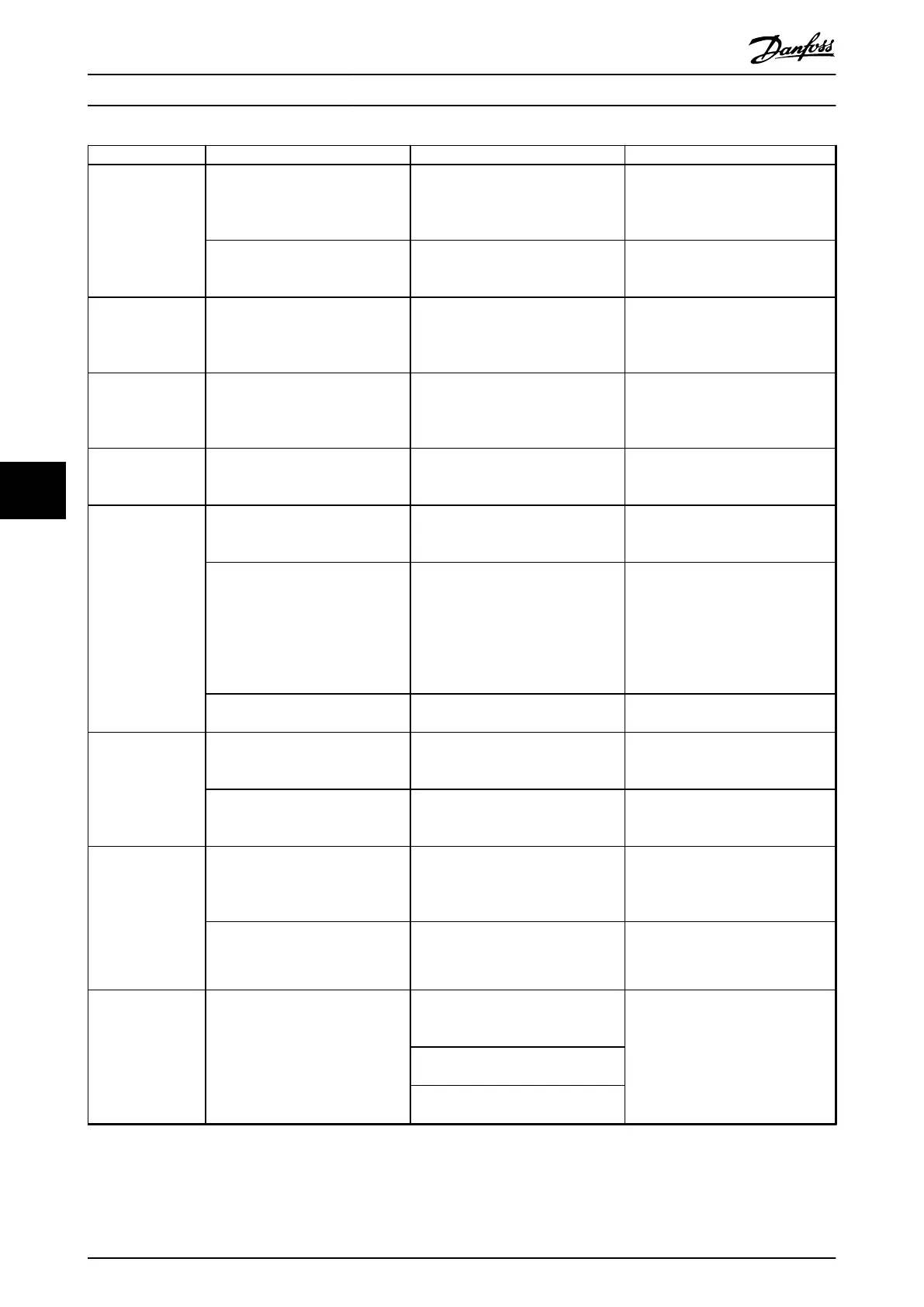

Symptom Possible cause Test Solution

Motor is not

reaching maximum

speed

Frequency limits are set incorrectly

Check output limits in

parameter 4-14 Motor Speed High Limit

[Hz] and parameter 4-19 Max Output

Frequency.

Program correct limits.

Reference input signal not scaled

correctly

Check reference input signal scaling in

parameter group 6-** Analog I/O mode

and parameter group 3-1* References.

Program correct settings.

Motor speed is

unstable

Possible incorrect parameter settings

Check the settings of all motor

parameters, including all motor

compensation settings. For closed-

loop operation, check PID settings.

Check settings in parameter group 6-

** Analog I/O mode.

Motor runs roughly Possible overmagnetization

Check for incorrect motor settings in

all motor parameters.

Check motor settings in parameter

groups 1-2* Motor data, 1-3* Adv

motor data, and 1-5* Load indep.

setting.

Motor does not

brake

Possible incorrect settings in the

brake parameters. Possible too short

ramp-down times.

Check brake parameters. Check ramp

time settings.

Check parameter groups 2-0* DC brake

and 3-0* Reference limits.

Open power fuses

or circuit breaker

trip

Phase-to-phase short

Motor or panel has a short phase-to-

phase. Check motor and panel phase

for shorts.

Eliminate any shorts detected.

Motor overload

Motor is overloaded for the

application.

Perform the start-up test and verify

that motor current is within speci-

cations. If motor current is exceeding

nameplate full load current, the

motor may run only with reduced

load. Review the specications for the

application.

Loose connections

Perform pre-start-up check for loose

connections.

Tighten loose connections.

Mains current

imbalance greater

than 3%

Problem with mains power (see

alarm 4, Mains phase loss

description)

Rotate input power leads into the

frequency converter 1 position: A to B,

B to C, C to A.

If the imbalanced leg follows the

wire, it is a power problem. Check

mains supply.

Problem with the frequency

converter unit

Rotate input power leads into the

frequency converter 1 position: A to B,

B to C, C to A.

If the imbalanced leg stays on same

input terminal, it is a problem with

the unit. Contact the supplier.

Motor current

imbalance greater

than 3%

Problem with motor or motor wiring

Rotate output motor leads 1 position:

U to V, V to W, W to U.

If the imbalanced leg follows the

wire, the problem is in the motor or

motor wiring. Check motor and

motor wiring.

Problem with the frequency

converter unit

Rotate output motor leads 1 position:

U to V, V to W, W to U.

If the imbalanced leg stays on same

output terminal, it is a problem with

the unit. Contact the supplier.

Acoustic noise or

vibration (for

example a fan blade

is making noise or

vibrations at certain

frequencies)

Resonances, for example, in the

motor/fan system

Bypass critical frequencies by using

parameters in parameter group 4-6*

Speed Bypass.

Check if noise and/or vibration have

been reduced to an acceptable limit.

Turn o overmodulation in

parameter 14-03 Overmodulation.

Increase resonance damping in

parameter 1-64 Resonance Dampening.

Table 7.4 Troubleshooting

Diagnostics and Troubleshoo...

VLT

®

AutomationDrive FC 360

52 Danfoss A/S © 03/2017 All rights reserved. MG06A702

77

Loading...

Loading...