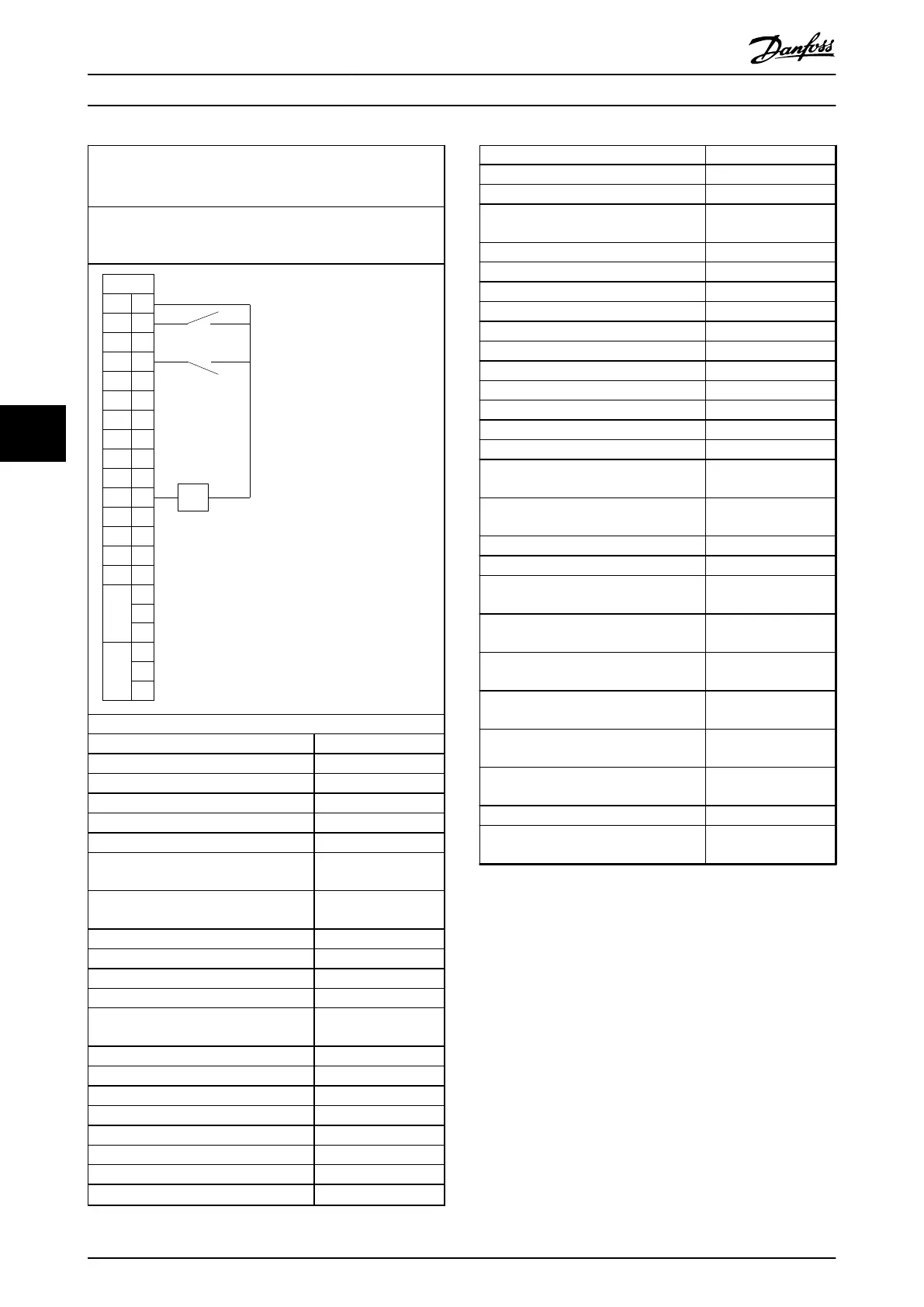

Application

One Gear Drive (OGD) V210.

Parameter 0-16 Application Selection is set to [7] OGD V210.

Description

For applications that use OGD. For example, conveyors in food

and beverage industries.

+24V 12

DI1 18

DI2 19

DI3 27

DI4 29

DI5 3

2DI6 3

3DI7 3

1

COM 20

+10V 50

AI1

53

-

+

AI2

54

COM 55

AO1

45AO2

42

1

2

3

4

5

6

R1

R2

FC 360

Start

Coast inverse

4-20

mA

130BD898.11

Parameter settings

Parameter Option/value

Parameter 1-00 Conguration Mode [0] Open Loop

Parameter 1-01 Motor Control Principle [1] VVC+

Parameter 1-08 Motor Control Bandwidth High

Parameter 1-10 Motor Construction [1] PM, non-salient SPM

Parameter 1-14 Damping Gain 120

Parameter 1-15 Low Speed Filter Time

Const.

0.175

Parameter 1-16 High Speed Filter Time

Const.

0.175

Parameter 1-17 Voltage lter time const. 0.035

Parameter 1-24 Motor Current 5.50

Parameter 1-25 Motor Nominal Speed 3000

Parameter 1-26 Motor Cont. Rated Torque 13.0

Parameter 1-29 Automatic Motor

Adaptation (AMA)

[0] O

Parameter 1-30 Stator Resistance (Rs) 1.000

Parameter 1-37 d-axis Inductance (Ld) 13.800

Parameter 1-39 Motor Poles 10

Parameter 1-40 Back EMF at 1000 RPM 155

Parameter 1-42 Motor Cable Length 50 m

Parameter 1-66 Min. Current at Low Speed 50

Parameter 1-73 Flying Start [2] Enable always

Parameter 2-06 Parking Current 10

Parameter 2-07 Parking Time 0.5

Parameter 2-10 Brake Function [0] O

Parameter 3-03 Maximum Reference 250 Hz

Parameter 4-14 Motor Speed High Limit

[Hz]

250 Hz

Parameter 4-16 Torque Limit Motor Mode 160

Parameter 4-18 Current Limit 160

Parameter 5-10 Terminal 18 Digital Input [8] Start

Parameter 5-11 Terminal 19 Digital Input [0] No operation

Parameter 5-12 Terminal 27 Digital Input [2] Coast inverse

Parameter 5-13 Terminal 29 Digital Input [0] No operation

Parameter 5-14 Terminal 32 Digital Input [0] No operation

Parameter 5-15 Terminal 33 Digital Input [0] No operation

Parameter 5-16 Terminal 31 Digital Input [0] No operation

Parameter 6-10 Terminal 53 Low Voltage 4.0 mA

Parameter 6-11 Terminal 53 High Voltage 20.0 mA

Parameter 6-14 Terminal 53 Low Ref./

Feedb. Value

0

Parameter 6-15 Terminal 53 High Ref./

Feedb. Value

250

Parameter 6-19 Terminal 53 mode [0] Current Mode

Parameter 14-01 Switching Frequency 10.0 kHz

Parameter 14-07 Dead Time Compen-

sation Level

65

Parameter 14-64 Dead Time Compen-

sation Zero Current Level

[0] Disabled

Parameter 14-65 Speed Derate Dead Time

Compensation

250

Parameter 14-51 DC-Link Voltage Compen-

sation

[0] O

Parameter 30-20 High Starting Torque

Time [s]

0

Parameter 30-21 High Starting Torque

Current [%]

100

Parameter 30-22 Locked Rotor Protection [0] O

Parameter 30-23 Locked Rotor Detection

Time [s]

1

Table 6.7 One Gear Drive (OGD) V210

6.2

Application Examples

6.2.1 Introduction

The examples in this section are intended as a quick

reference for common applications.

•

Parameter settings are the regional default values

unless otherwise indicated (selected in

parameter 0-03 Regional Settings).

•

Parameters associated with the terminals and

their settings are shown next to the drawings.

•

Required switch settings for analog terminals 53

or 54 are also shown.

Applications

VLT

®

AutomationDrive FC 360

42 Danfoss A/S © 03/2017 All rights reserved. MG06A702

6

6

Loading...

Loading...