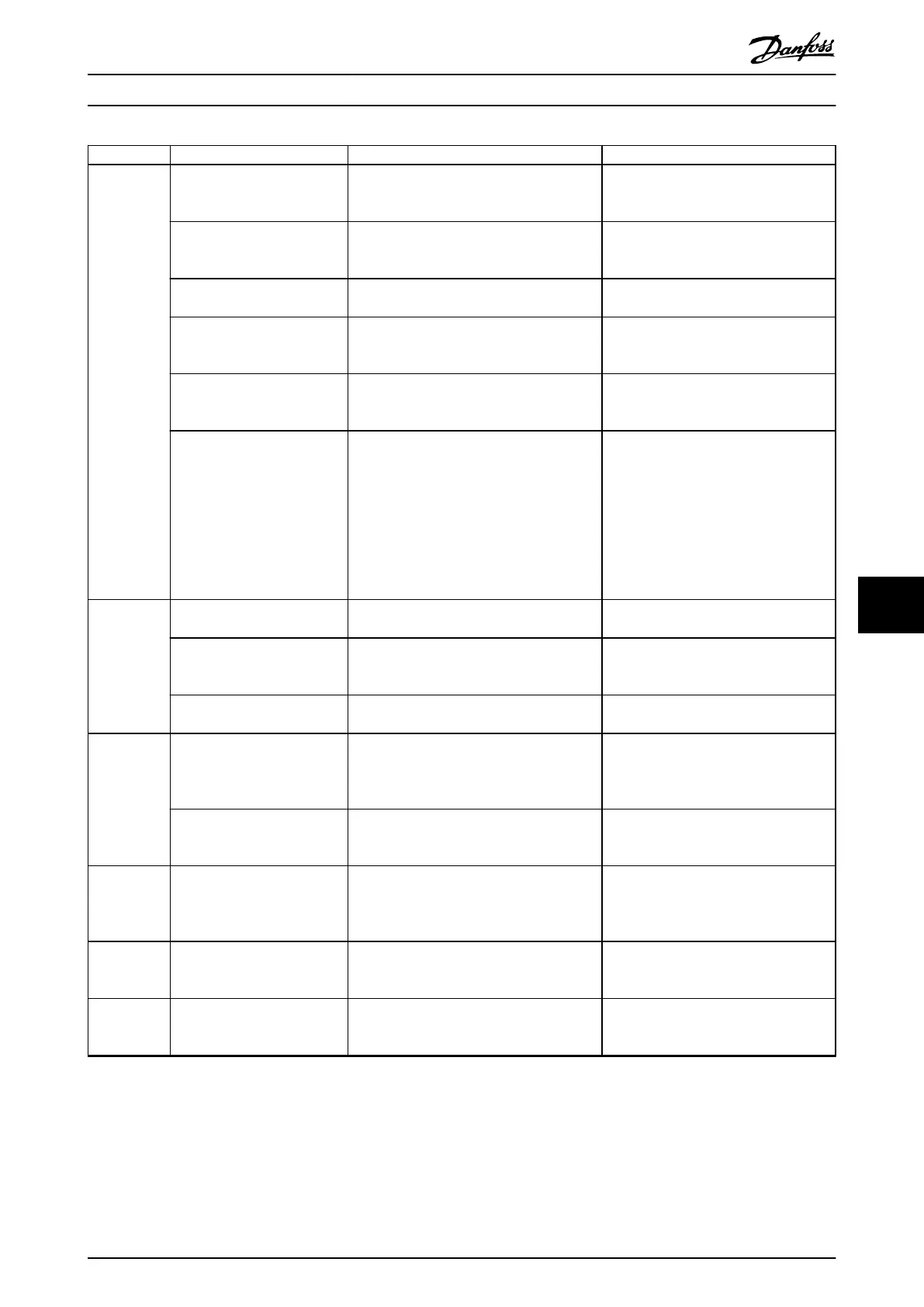

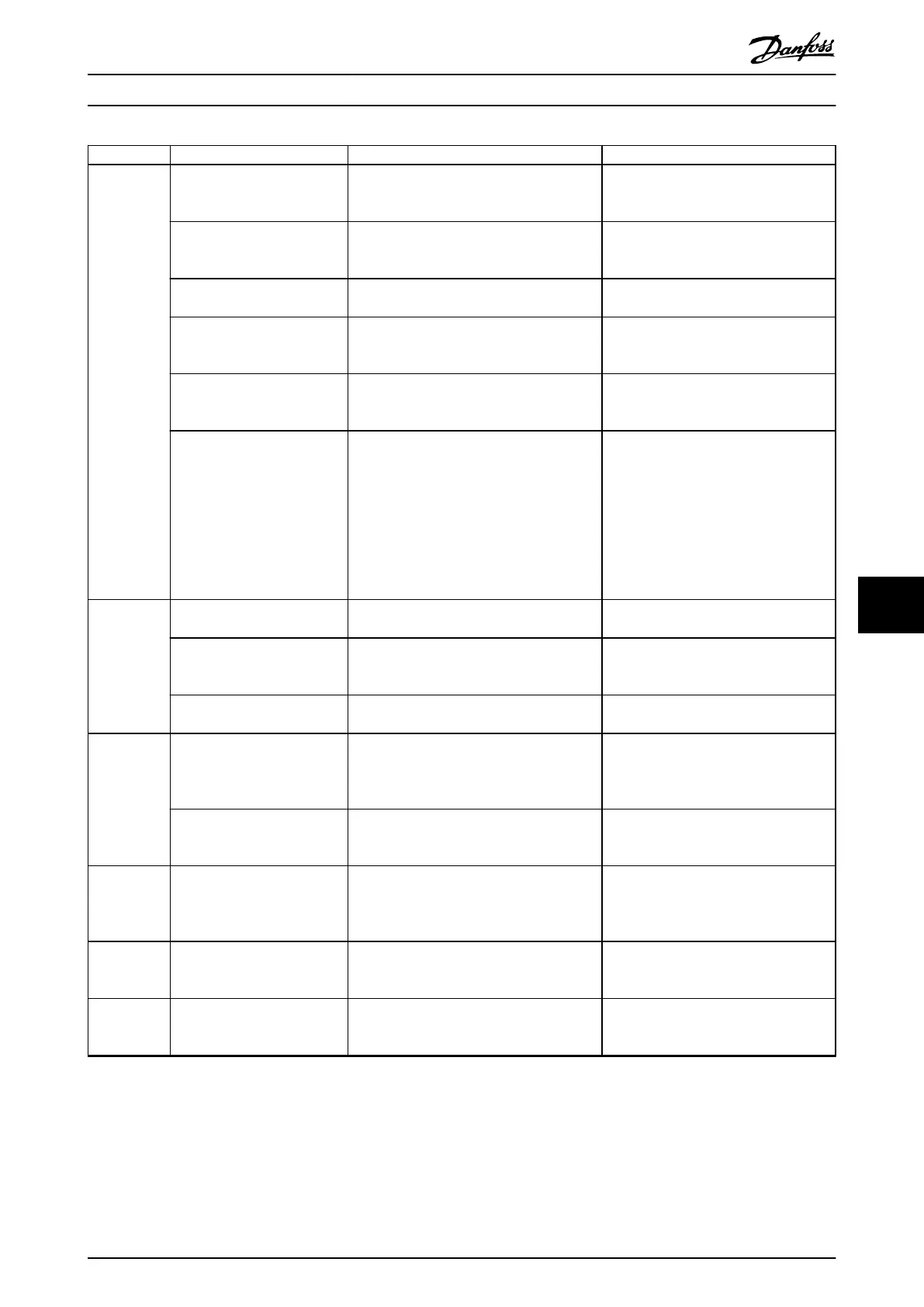

Symptom Possible cause Test Solution

Motor not

running

Service switch open or missing

motor connection.

Check if the motor is connected and the

connection is not interrupted by a service

switch or other device.

Connect the motor and check the service

switch.

No mains power with 24 V DC

option card.

If the display is functioning, but there is no

output, check that mains power is applied to

the AC drive.

Apply mains power.

LCP Stop. Check if [O] has been pressed. Press [Auto On] or [Hand On] (depending

on operating mode).

Missing start signal (Standby). Check parameter 5-10 Terminal 18 Digital Input

for correct setting for terminal 18. Use default

setting.

Apply a valid start signal.

Motor coast signal active

(Coasting).

Check parameter 5-12 Terminal 27 Digital Input

for correct setting for terminal 27 (use default

setting).

Apply 24 V on terminal 27 or program

this terminal to [0] No operation.

Wrong reference signal source. Check reference signal:

•

Local.

•

Remote or bus reference?

•

Preset reference active?

•

Terminal connection correct?

•

Scaling of terminals correct?

•

Reference signal available?

Program correct settings. Check

parameter 3-13 Reference Site. Set preset

reference active in parameter group 3-1*

References. Check for correct wiring. Check

scaling of terminals. Check reference

signal.

Motor

running in

wrong

direction

Motor rotation limit. Check that parameter 4-10 Motor Speed

Direction is programmed correctly.

Program correct settings.

Active reversing signal. Check if a reversing command is programmed

for the terminal in parameter group 5-1*

Digital inputs.

Deactivate reversing signal.

Wrong motor phase

connection.

– See chapter 7.3.1 Warning - Motor Start.

Motor is not

reaching

maximum

speed

Frequency limits set wrong. Check output limits in parameter 4-13 Motor

Speed High Limit [RPM], parameter 4-14 Motor

Speed High Limit [Hz], and parameter 4-19 Max

Output Frequency

Program correct limits.

Reference input signal not

scaled correctly.

Check reference input signal scaling in

parameter group 6-0* Analog I/O mode and

parameter group 3-1* References.

Program correct settings.

Motor speed

unstable

Possible incorrect parameter

settings.

Check the settings of all motor parameters,

including all motor compensation settings.

For closed-loop operation, check PID settings.

Check settings in parameter group 1-6*

Load Depen. Setting. For closed-loop

operation, check settings in parameter

group 20-0* Feedback.

Motor runs

rough

Possible overmagnetization. Check for incorrect motor settings in all

motor parameters.

Check motor settings in parameter groups

1-2* Motor data, 1-3* Adv Motor Data, and

1-5* Load Indep. Setting.

Motor does

not brake

Possible incorrect settings in

the brake parameters. Ramp-

down times may be too short.

Check brake parameters. Check ramp time

settings.

Check parameter groups 2-0* DC Brake and

3-0* Reference Limits.

Maintenance, Diagnostics, a... Operating Guide

MG06I102 Danfoss A/S © 06/2018 All rights reserved. 55

9 9

Loading...

Loading...