[84] SL Digital Output E See par. 13-52

SL Control Action

. The input will go high whenever the Smart Logic Action [42]

Set dig. out. E

high

is executed. The input will go low whenever the Smart Logic Action [36]

Set dig. out. E low

is executed.

[85] SL Digital Output F See par. 13-52

SL Control Action

. The input will go high whenever the Smart Logic Action [43]

Set dig. out. F

high

is executed. The input will go low whenever the Smart Logic Action [37]

Set dig. out. F low

is executed.

[160] No alarm The output is high when no alarm is present.

[161] Running reverse The output is high when the frequency converter is running counter clockwise (the logical product of the status

bits ‘running’ AND ‘reverse’).

[165] Local reference active The output is high when par. 3-13

Reference Site

= [2] Local or when par. 3-13

Reference Site

= [0]

Linked to

hand auto

at the same time as the LCP is in Hand on mode.

[166] Remote reference ac-

tive

The output is high when par. 3-13

Reference Site = Remote

[1] or

Linked to hand/auto

[0] while the LCP is in

[Auto on] mode.

[167] Start command active The output is high when there is an active Start command (i.e. via digital input bus connection or [Hand on] or

[Auto on], and no Stop or Start command is active.

[168] Drive in hand mode The output is high when the frequency converter is in Hand on mode (as indicated by the LED light above [Hand

on].

[169] Drive in auto mode The output is high when the frequency converter is in Hand on mode (as indicated by the LED light above [Auto

on].

[180] Clock Fault The clock function has been reset to default (2000-01-01) because of a power failure.

[181] Preventive Mainte-

nance

One or more of the Preventive Maintenance Events programmed in par. 23-10, Preventive Maintenance Item,

has passed the time for the specified action in par. 23-11, Maintenance Action.

[190] No-Flow A No-Flow situation or Minimum Speed situation has been detected if enabled in

Minimum Speed Detection

. par.

22-21 and/or

No-Flow Detection

, par. 22-22.

[191] Dry Pump A Dry Pump condition has been detected. This function must be enabled in par. 22-26, Dry Pump Function.

[192] End of Curve A pump running with max. speed for a period of time without reaching the set pressure has been detected. To

enable this function please see

par. 22-50 End of Curve Function

.

[193] Sleep Mode The frequency converter/system has turned into sleep mode. See

Sleep mode

, par. 22-4*.

[194] Broken Belt A Broken Belt condition has been detected. This function must be enabled in par. 22-60, Broken Belt Detection.

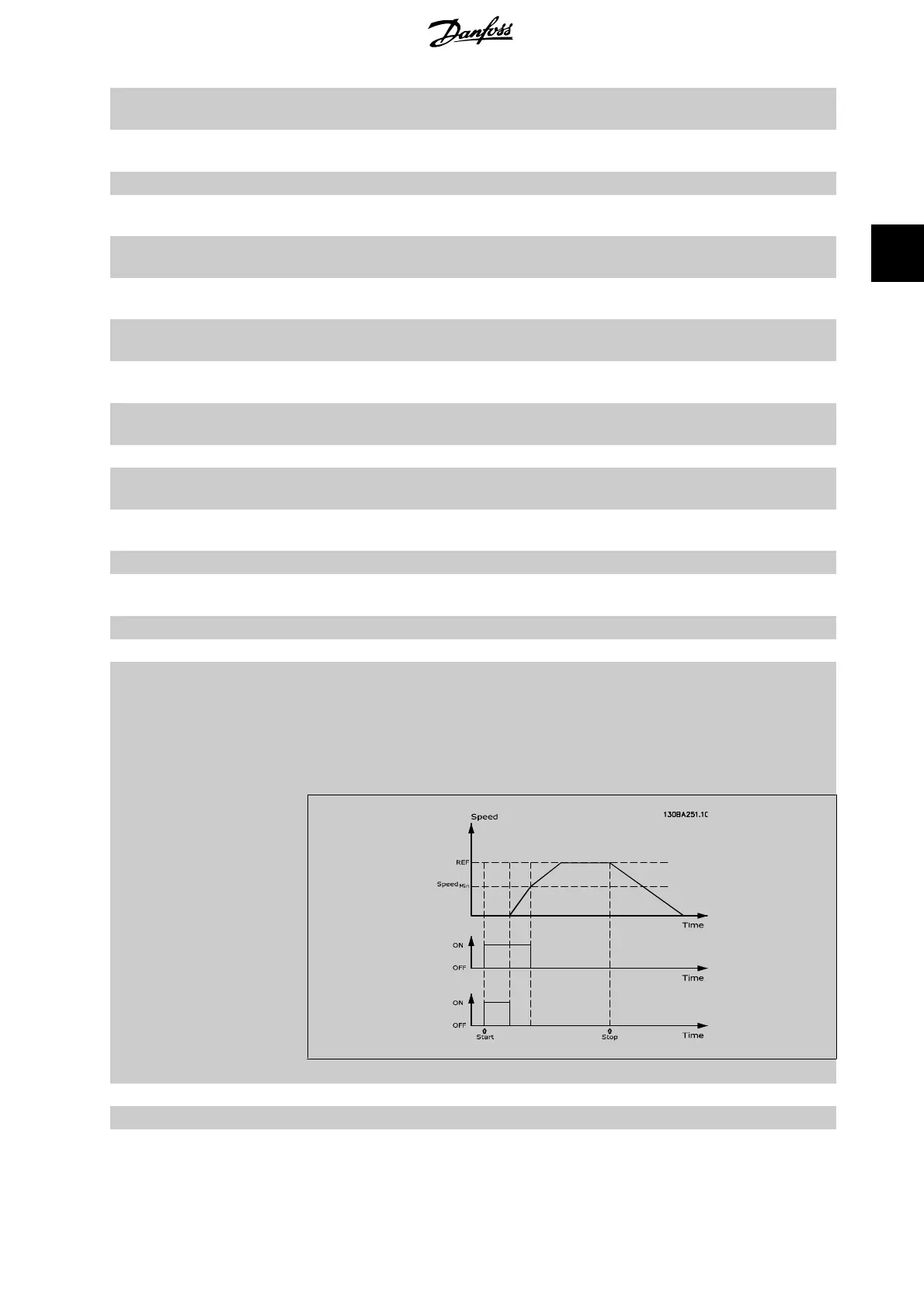

[195] Bypass Valve Control The bypass valve control (Digital / Relay output in the frequency converter) is used for compressor systems to

unload the compressor during start-up by using a bypass valve. After the start command is given the bypass

valve will be open until the frequency converter reaches

Motor speed low limit

, par. 4 -11) . After the limit has

been reached the bypass valve will be closed, allowing the compressor to operate normally. This procedure will

not be activated again before a new start is initiated and the frequency converter speed is zero during the

receiving of start signal.

Start Delay

, par. 1-71 can be used in order to delay the motor start. The Bypass valve

control principle:

[196] Fire Mode The frequency converter is operating in Fire Mode. See 24-0*

Fire Mode

.

[197] Fire Mode was act. The frequency converter has been operating in Fire Mode, but is now back in normal operation.

[198] Drive Bypass To be used as signal for activating an external electromechanical bypass switching the motor direct on line. See

24-1*

Drive Bypass

.

VLT

®

HVAC Drive Programming Guide 3. Parameter Description

MG.11.C5.02 - VLT

®

is a registered Danfoss trademark

71

3

Loading...

Loading...