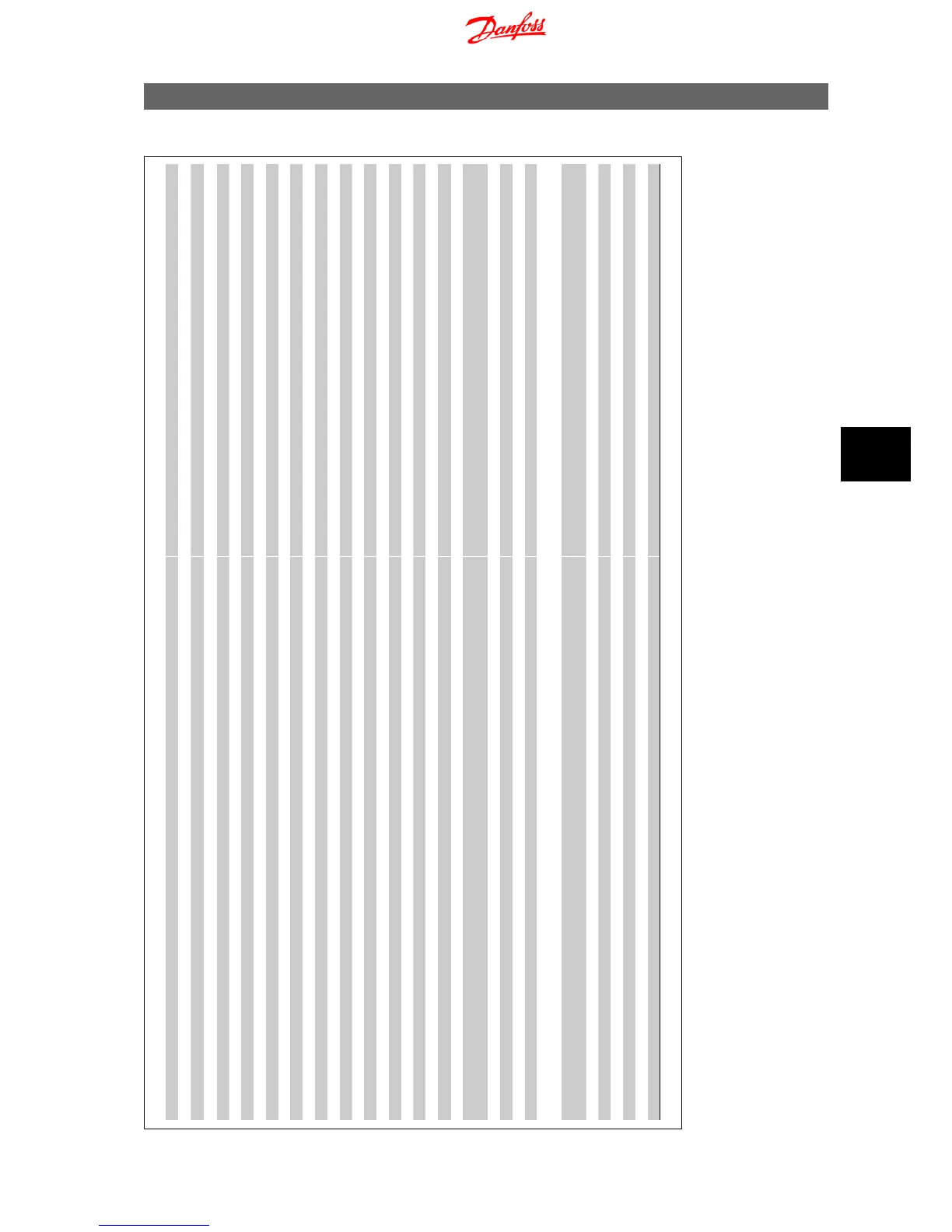

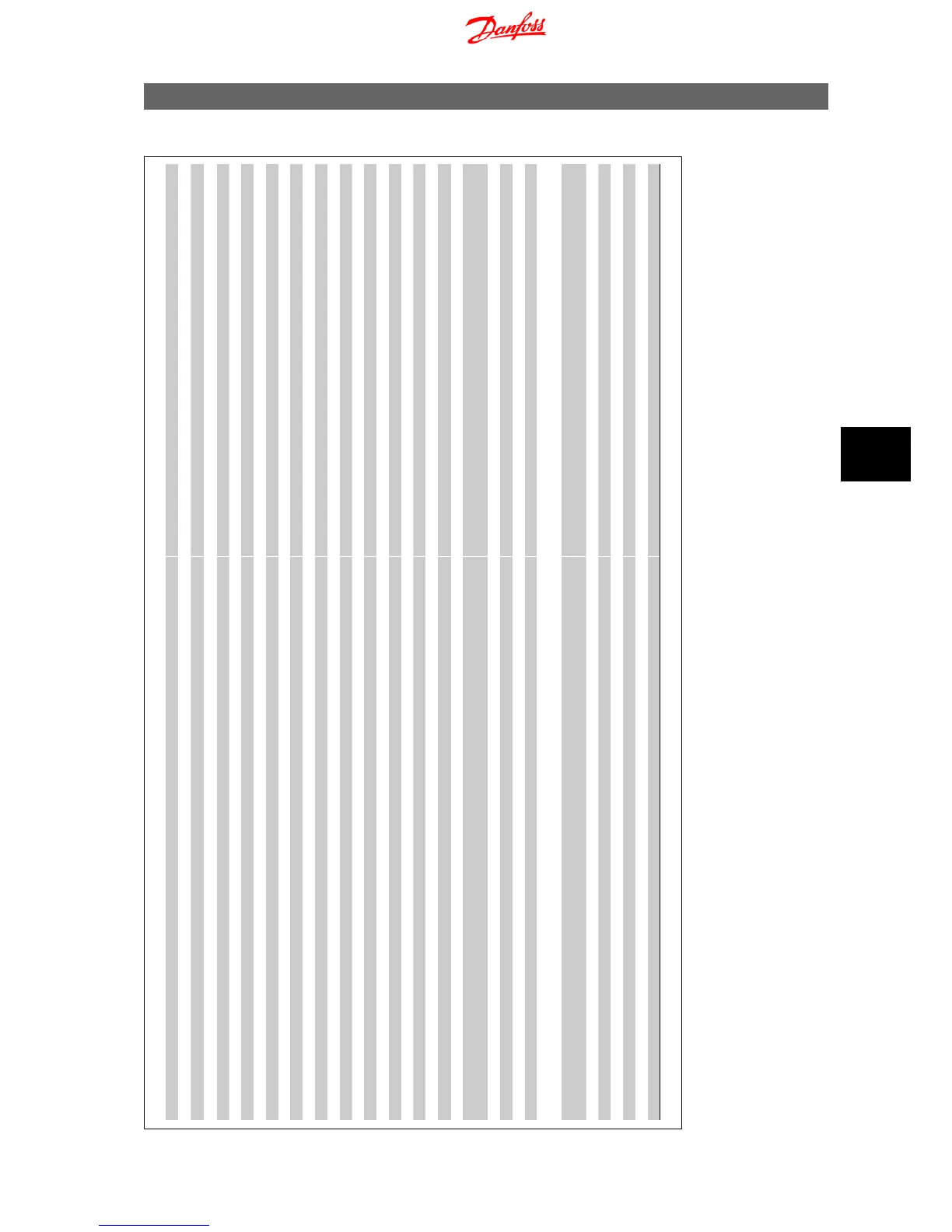

7 Troubleshooting

No. Description Warning Alarm Trip Lock Error Cause of Problem

2 Live zero error X X Signal on terminal 53 or 60 is less than 50% of value set in par. 6-10, 6-12 and 6-22.

4

Mains phase loss

1)

X X X Missing phase on supply side, or too high voltage imbalance. Check supply voltage.

7

DC over voltage

1)

X X Intermediate circuit voltage exceeds limit.

8

DC under voltage

1)

X X Intermediate circuit voltage drops below “voltage warning low” limit.

9 Inverter overloaded X X More than 100% load for too long.

10 Motor ETR over temperature X X Motor is too hot due to more than 100% load for too long.

11 Motor thermistor over temperature X X Thermistor or thermistor connection is disconnected.

12 Torque limit X Torque exceeds value set in either par. 4-16 or 4-17.

13 Over Current X X X Inverter peak current limit is exceeded.

14 Earth fault X X Discharge from output phases to ground.

16 Short Circuit X X Short-circuit in motor or on motor terminals.

17 Control word timeout X X No communication to frequency converter.

25 Brake resistor short-circuited X X Brake resistor is short-circuited, thus brake function is disconnected.

27 Brake chopper short-circuited X X Brake transistor is short-circuited, thus brake function is disconnected.

28 Brake check X Brake resistor is not connected/working

29 Power board over temp X X X Heat-sink cut-out temperature has been reached.

30 Motor phase U missing X X Motor phase U is missing. Check the phase.

31 Motor phase V missing X X Motor phase V is missing. Check the phase.

32 Motor phase W missing X X Motor phase W is missing. Check the phase.

38 Internal fault X X Contact local Danfoss supplier.

47 Control Voltage Fault X X X 24 V DC may be overloaded.

51 AMT check U

nom

and I

nom

X Wrong setting for motor voltage and/or motor current.

52 AMT low I

nom

X Motor current is too low. Check settings.

59 Current limit X VLT overload.

63 Mechanical Brake Low X Actual motor current has not exceeded “release brake” current within “start delay” time

window.

80 Drive Initialised to Default Value X All parameter settings are initialized to default settings.

84 The connection between drive and LCP is lost X No communication between LCP and frequency converter

85 Button disabled X See parameter group 0-4*

LCP

86 Copy fail X An error occurred while copying from frequency converter to LCP or vice versa.

87 LCP data invalid X Occurs when copying from LCP if the LCP contains erroneous data - or if no data was

uploaded to the LCP.

88 LCP data not compatible X Occurs when copying from LCP if data are moved between frequency converters with

major differences in software versions.

89 Parameter read only X Occurs when trying to write to a read-only parameter.

90 Parameter database busy X LCP and RS485 connection are trying to update parameters simultaneously.

91 Parameter value is not valid in this mode X Occurs when trying to write an illegal value to a parameter.

92 Parameter value exceeds the min/max limits X Occurs when trying to set a value outside the range.

nw run Not While RUNning X Parameter can only be changed when the motor is stopped.

Err. A wrong password was entered X Occurs when using a wrong password for changing a password-protected parameter.

1)

These faults may be caused by mains distortions. Installing Danfoss Line Filter may rectify this problem.

Table 7.1: Warnings and Alarms

Code list

VLT

®

Micro Drive FC 51 Operating Instructions 7 Troubleshooting

MG.02.A4.02 - VLT

®

is a registered Danfoss trademark

59

7

Loading...

Loading...