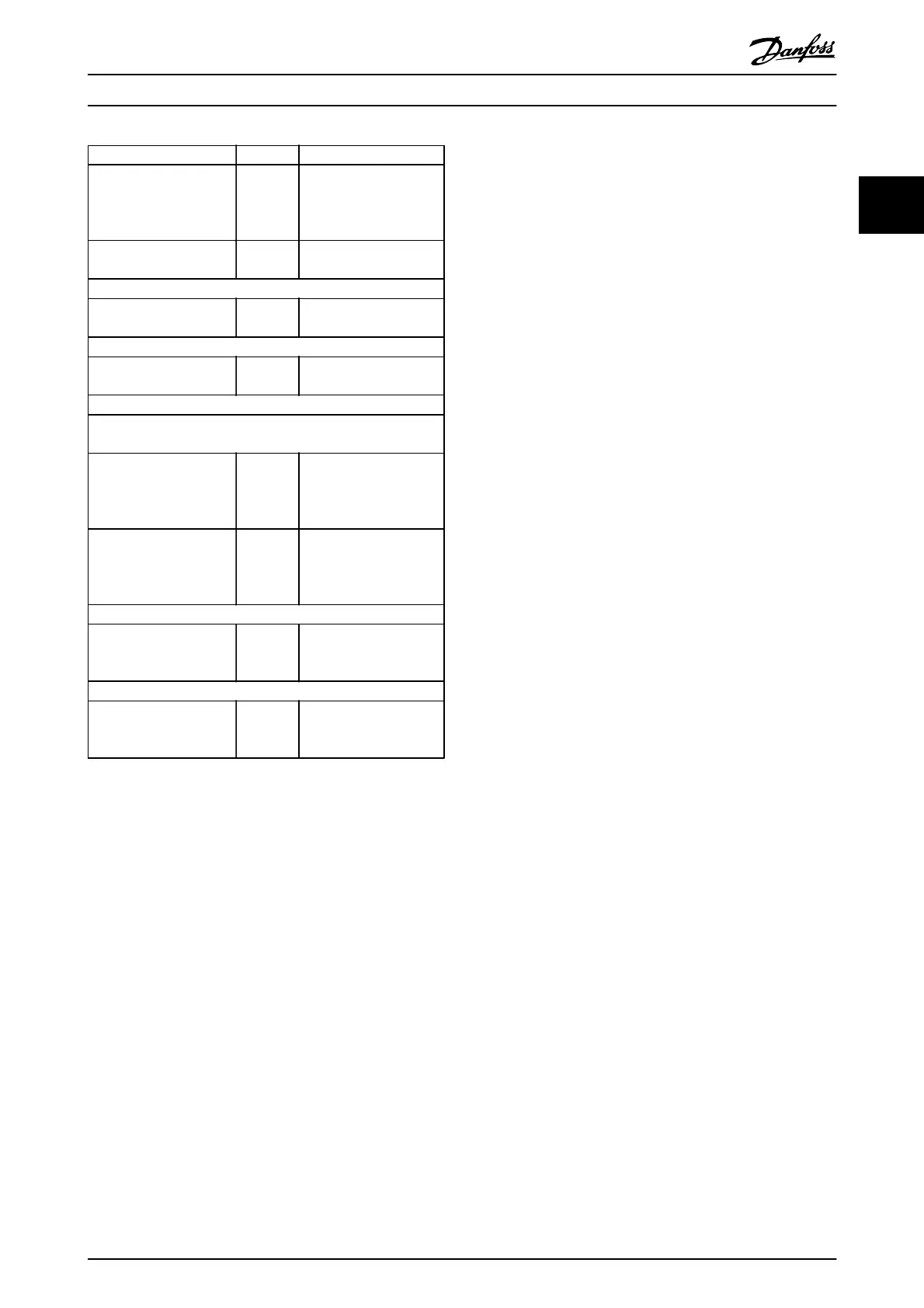

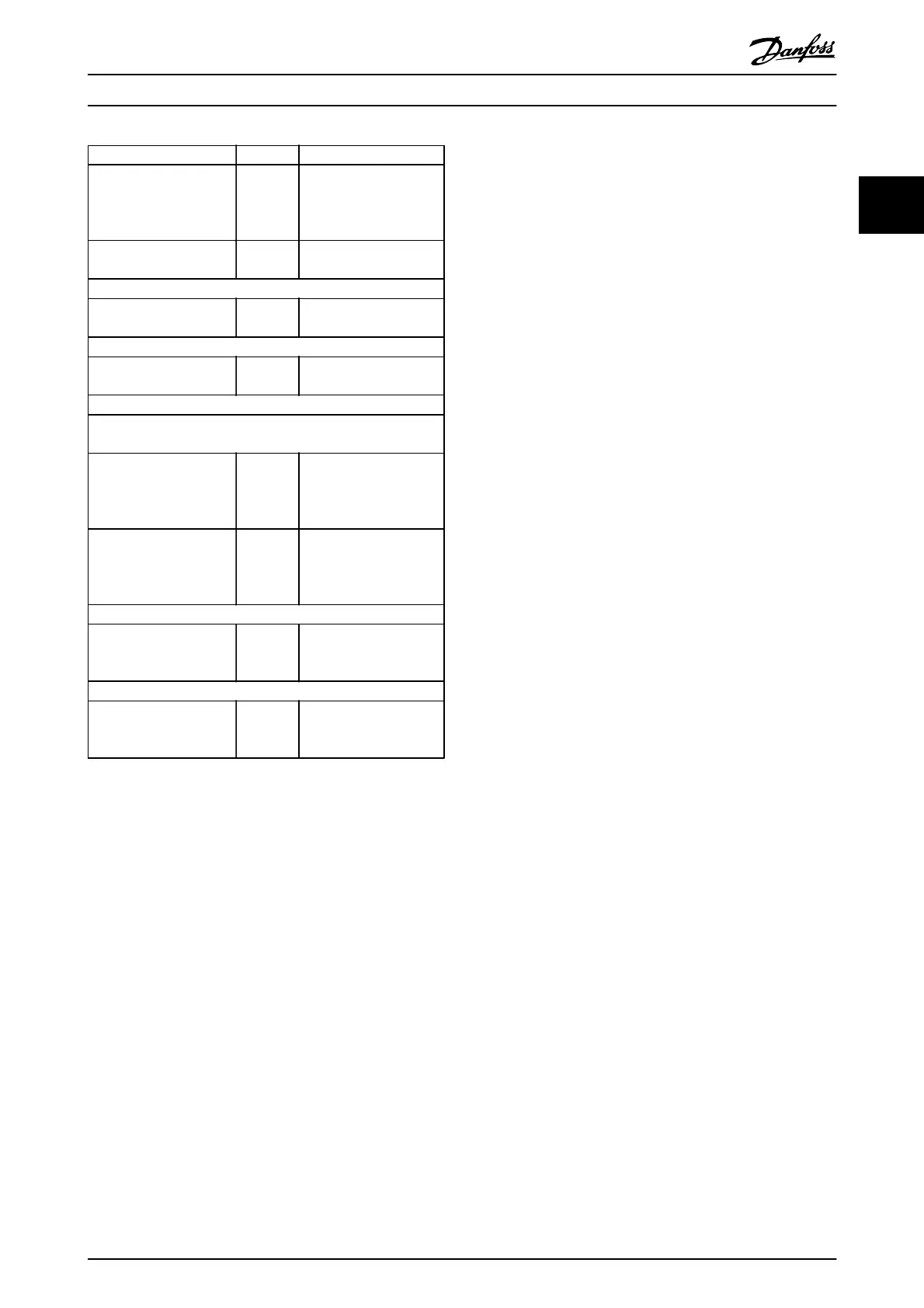

Function Par. no. Setting

Set acceptable limits for

the motor speed.

4-12

4-14

4-19

10 Hz, Motor min speed

50 Hz, Motor max speed

50 Hz, Drive max output

frequency

Switch from open loop to

closed loop.

1-00 [3] Closed Loop

4) Configure the feedback to the PID controller.

Select the appropriate

reference/feedback unit.

20-12 [71] Bar

5) Configure the set-point reference for the PID controller.

Set acceptable limits for

the set-point reference.

20-13

20-14

0 Bar

10 Bar

Choose current or voltage by switches S201 / S202

6) Scale the analog inputs used for set-point reference and

feedback.

Scale Analog Input 53 for

the pressure range of the

potentiometer (0 - 10 Bar,

0 - 10 V).

6-10

6-11

6-14

6-15

0 V

10 V (default)

0 Bar

10 Bar

Scale Analog Input 54 for

pressure sensor (0 - 10

Bar, 4 - 20 mA)

6-22

6-23

6-24

6-25

4 mA

20 mA (default)

0 Bar

10 Bar

7) Tune the PID controller parameters.

Adjust the drive’s Closed

Loop Controller, if

needed.

20-93

20-94

See Optimization of the

PID Controller, below.

8) Finished!

Save the parameter

setting to the LCP for safe

keeping

0-50 [1] All to LCP

Table 2.8

2.8.10 Tuning the Drive Closed Loop

Controller

Once the frequency converter's Closed Loop Controller has

been set up, the performance of the controller should be

tested. In many cases, its performance may be acceptable

using the default values of 20-93 PID Proportional Gain and

20-94 PID Integral Time. However, in some cases it may be

helpful to optimize these parameter values to provide

faster system response while still controlling speed

overshoot.

2.8.11 Manual PID Adjustment

1. Start the motor

2. Set 20-93 PID Proportional Gain to 0.3 and

increase it until the feedback signal begins to

oscillate. If necessary, start and stop the drive or

make step changes in the set-point reference to

attempt to cause oscillation. Next reduce the PID

Proportional Gain until the feedback signal

stabilizes. Then reduce the proportional gain by

40-60%.

3.

Set 20-94 PID Integral Time to 20 s and reduce it

until the feedback signal begins to oscillate. If

necessary, start and stop the drive or make step

changes in the set-point reference to attempt to

cause oscillation. Next, increase the PID Integral

Time until the feedback signal stabilizes. Then

increase of the Integral Time by 15-50%.

4. 20-95 PID Differentiation Time should only be used

for very fast-acting systems. The typical value is

25% of 20-94 PID Integral Time. The differential

function should only be used when the setting of

the proportional gain and the integral time has

been fully optimized. Make sure that oscillations

of the feedback signal are sufficiently dampened

by the low-pass filter for the feedback signal

(parameters 6-16, 6-26, 5-54 or 5-59 as required).

2.9 General Aspects of EMC

2.9.1 General Aspects of EMC Emissions

Electrical interference is usually conducted at frequencies

in the range 150 kHz to 30 MHz. Airborne interference

from the frequency converter system in the range 30 MHz

to 1 GHz is generated from the inverter, motor cable, and

the motor.

As shown in Illustration 2.20, capacitive currents in the

motor cable coupled with a high dU/dt from the motor

voltage generate leakage currents.

The use of a screened motor cable increases the leakage

current (see Illustration 2.20) because screened cables have

higher capacitance to earth than unscreened cables. If the

leakage current is not filtered, it will cause greater

interference on the mains in the radio frequency range

below approximately 5 MHz. Since the leakage current (I

1

)

is carried back to the unit through the screen (I

3

), there

will in principle only be a small electro-magnetic field (I

4

)

from the screened motor cable according to the below

figure.

The screen reduces the radiated interference but increases

the low-frequency interference on the mains. The motor

cable screen must be connected to the frequency

converter enclosure as well as on the motor enclosure. This

is best done by using integrated screen clamps so as to

avoid twisted screen ends (pigtails). These increase the

screen impedance at higher frequencies, which reduces the

screen effect and increases the leakage current (I

4

).

If a screened cable is used for fieldbus, relay, control cable,

signal interface and brake, the screen must be mounted on

the enclosure at both ends. In some situations, however, it

Introduction

VLT

®

Refrigeration Drive Design Guide

MG16G102 - VLT

®

is a registered Danfoss trademark 25

2

Loading...

Loading...