2.9.8 EMC Test Results (Emission)

The following test results have been obtained using a

system with a frequency converter (with options if

relevant), a screeened control cable, a control box with

potentiometer, as well as a motor and motor screened

cable.

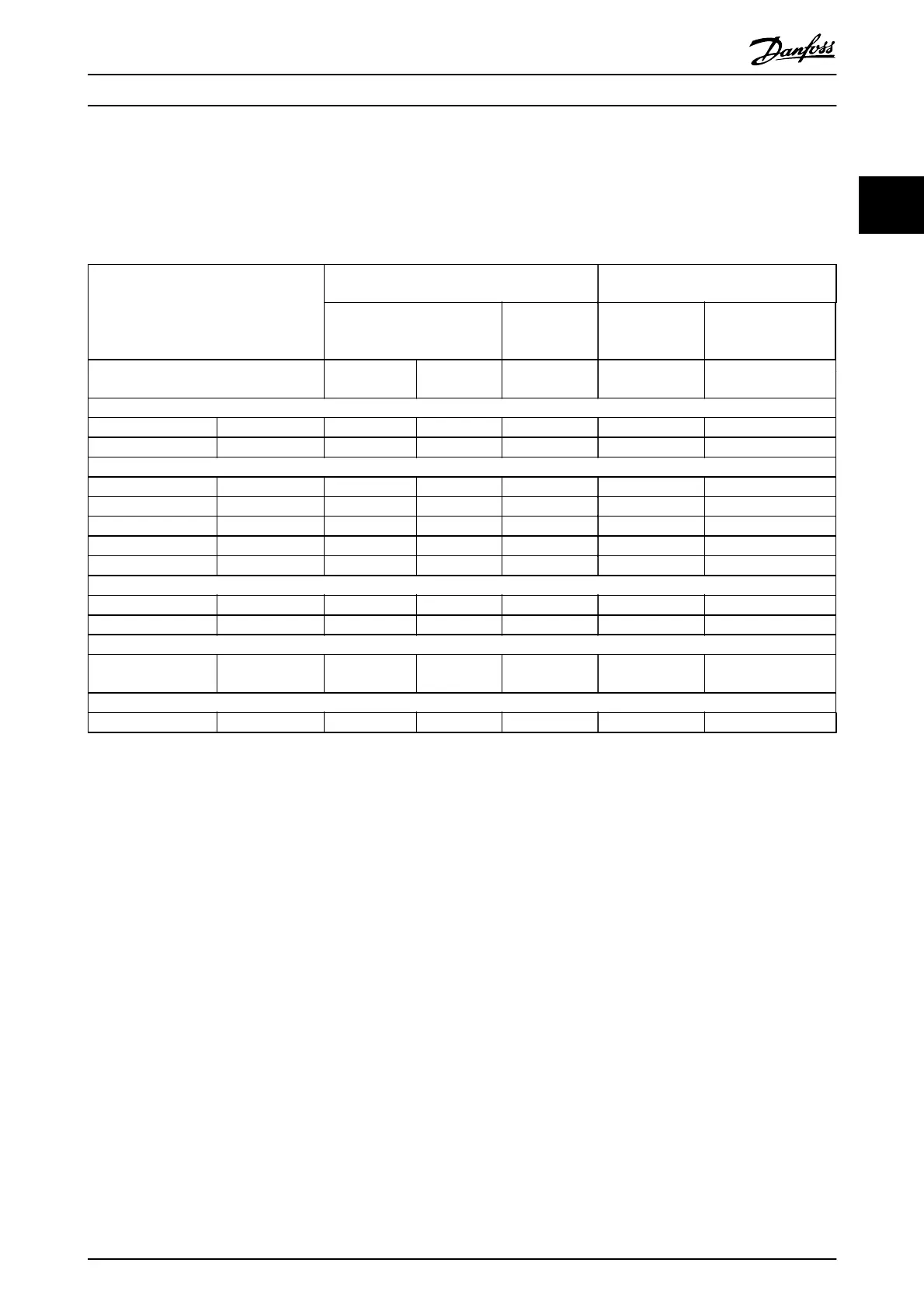

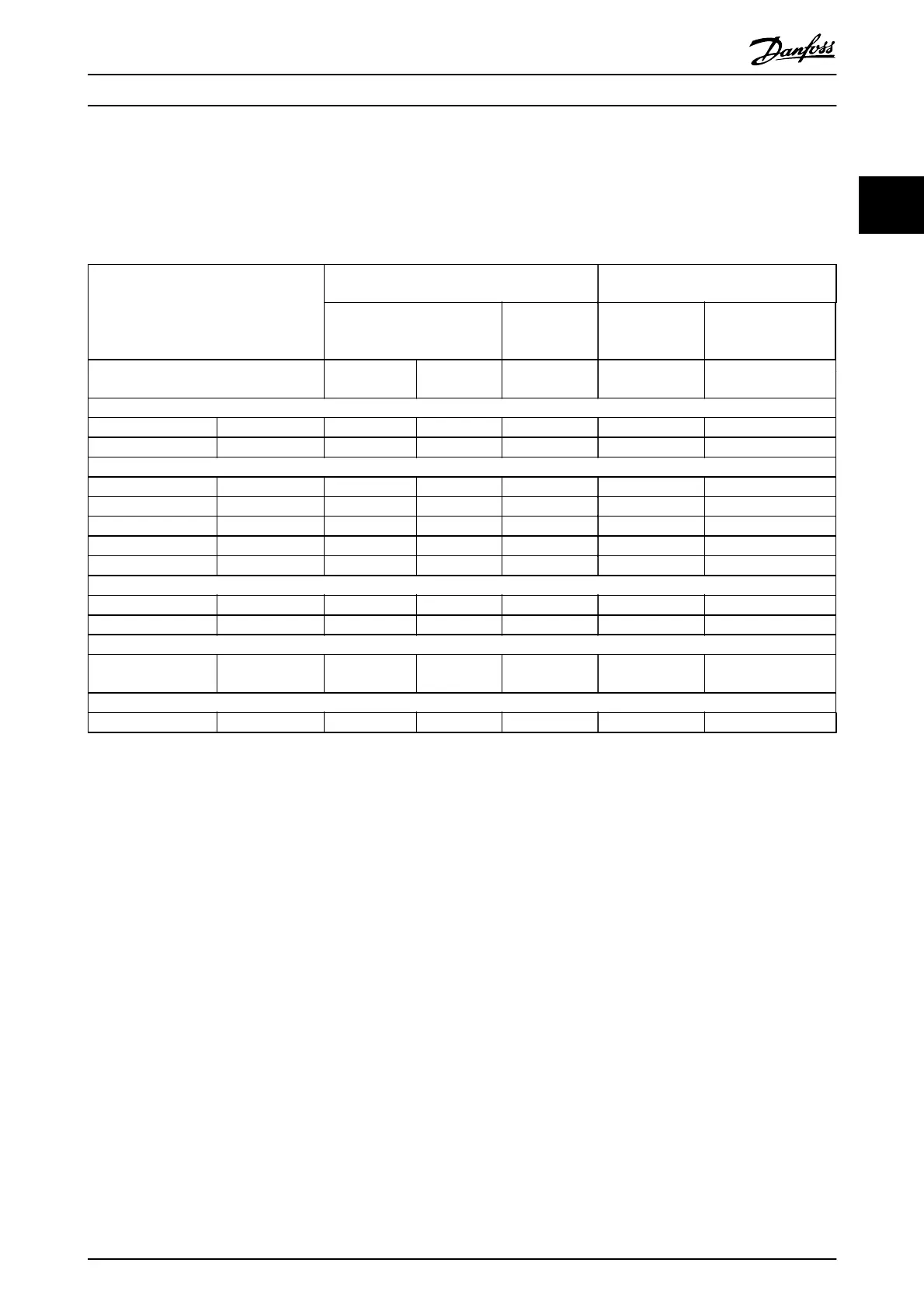

RFI filter type Conducted emission

Maximum shielded cable length

Radiated emission

Industrial environment Housing,

trades and

light industries

Industrial

environment

Housing, trades and

light industries

Standard EN 55011

Class A2

EN 55011

Class A1

EN 55011

Class B

EN 55011

Class A1

EN 55011

Class B

H1

1.1-45 kW 200-240 V T2 150 m 150 m 50 m Yes No

1.1-90 kW 380-480 V T4 150 m 150 m 50 m Yes No

H2

1.1-3.7 kW 200-240 V T2 5 m No No No No

5.5-45 kW 200-240 V T2 25 m No No No No

1.1-7.5 kW 380-480 V T4 5 m No No No No

11-90 kW 380-480 V T4 25 m No No No No

110-250 kW 380-480 V T4 150 m No No No No

H3

1.1-45 kW 200-240 V T2 75 m 50 m 10 m Yes No

1.1-90 kW 380-480 V T4 75 m 50 m 10 m Yes No

H4

110-1000 kW 380-480

V

T4 150 m 150 m No Yes No

Hx

1.1-90 kW 525-600 V T6 - - - - -

Table 2.15 EMC Test Results (Emission)

HX, H1, H2 or H3 is defined in the type code pos. 16 - 17 for EMC

filters

HX - No EMC filters built in the frequency converter (600 V units only)

H1 - Integrated EMC filter. Fulfil Class A1/B

H2 - No additional EMC filter. Fulfil Class A2

H3 - Integrated EMC filter. Fulfil class A1/B (Frame size A1 only)

H4 - Integrated EMC filter. Fulfil class A1

2.10 Galvanic isolation (PELV)

2.10.1 PELV - Protective Extra Low Voltage

PELV offers protection by way of extra low voltage.

Protection against electric shock is ensured when the

electrical supply is of the PELV type and the installation is

made as described in local/national regulations on PELV

supplies.

All control terminals and relay terminals 01-03/04-06

comply with PELV (Protective Extra Low Voltage), with the

exception of grounded Delta leg above 400 V.

Galvanic (ensured) isolation is obtained by fulfilling

requirements for higher isolation and by providing the

relevant creepage/clearance distances. These requirements

are described in the EN 61800-5-1 standard.

The components that make up the electrical isolation, as

described below, also comply with the requirements for

higher isolation and the relevant test as described in EN

61800-5-1.

The PELV galvanic isolation can be shown in six locations

(see Illustration 2.22):

In order to maintain PELV all connections made to the

control terminals must be PELV, e.g. thermistor must be

reinforced/double insulated.

1. Power supply (SMPS) incl. signal isolation of U

DC

,

indicating the voltage of intermediate DC Link

circuit.

2. Gate drive that runs the IGBTs (trigger

transformers/opto-couplers).

3. Current transducers.

Introduction

VLT

®

Refrigeration Drive Design Guide

MG16G102 - VLT

®

is a registered Danfoss trademark 31

2

Loading...

Loading...