Furthermore, the terminal screw must be retightened after

two days due to the softness of the aluminium. It is crucial

to keep the connection a gas tight joint, otherwise the

aluminium surface will oxidize again.

5.2.5 Removal of Knockouts for Extra

Cables

1. Remove cable entry from the frequency converter

(Avoiding foreign parts falling into the frequency

converter when removing knockouts)

2. Cable entry has to be supported around the

knockout you intend to remove.

3. The knockout can now be removed with a strong

mandrel and a hammer.

4. Remove burrs from the hole.

5. Mount Cable entry on frequency converter.

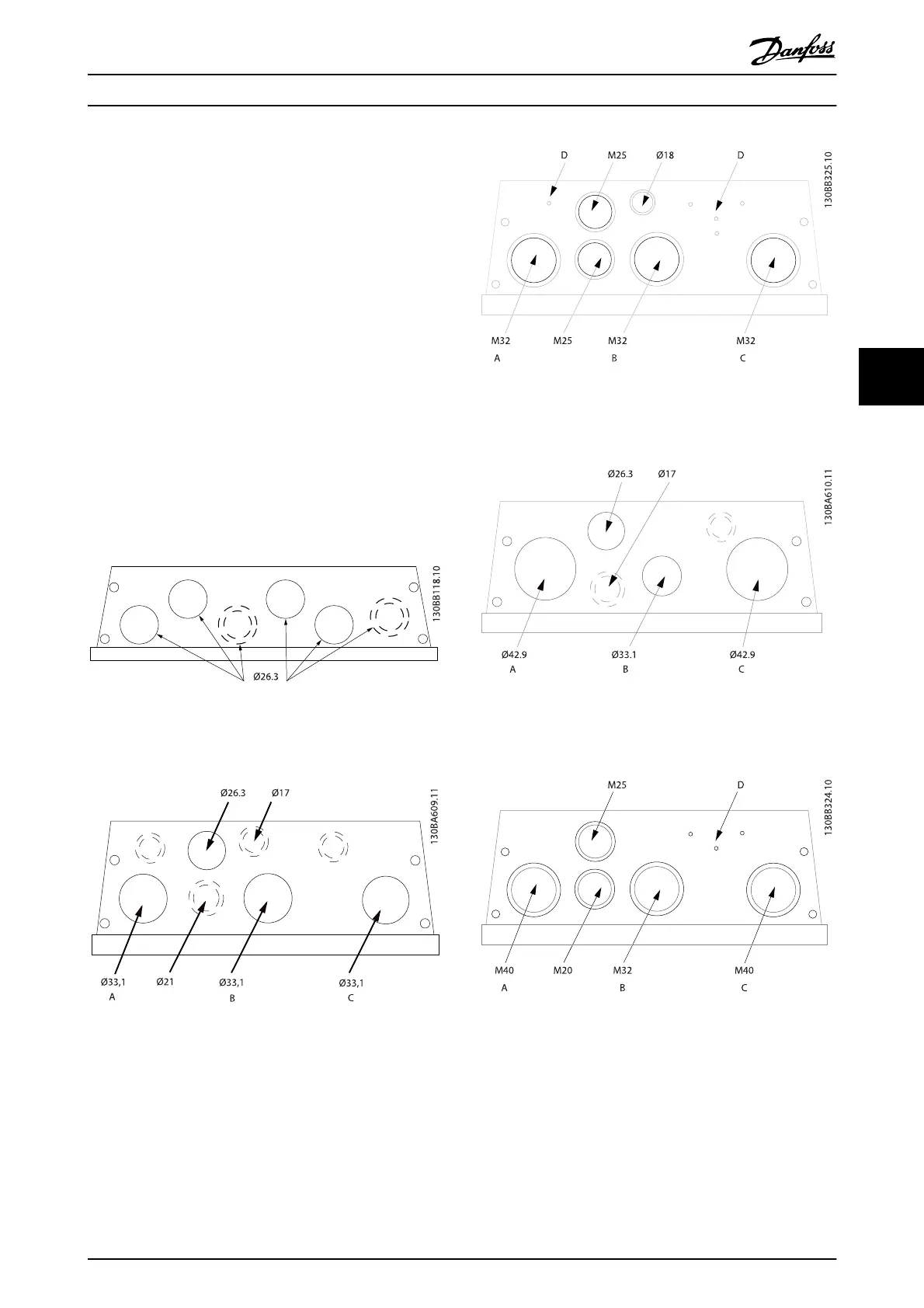

5.2.6 Enclosure Knock-outs

Illustration 5.7 Cable entry holes for enclosure A5. The

suggested use of the holes are purely recommendations and

other solutions are possible.

Illustration 5.8 Cable entry holes for enclosure B1. The suggested

use of the holes are purely recommendations and other

solutions are possible.

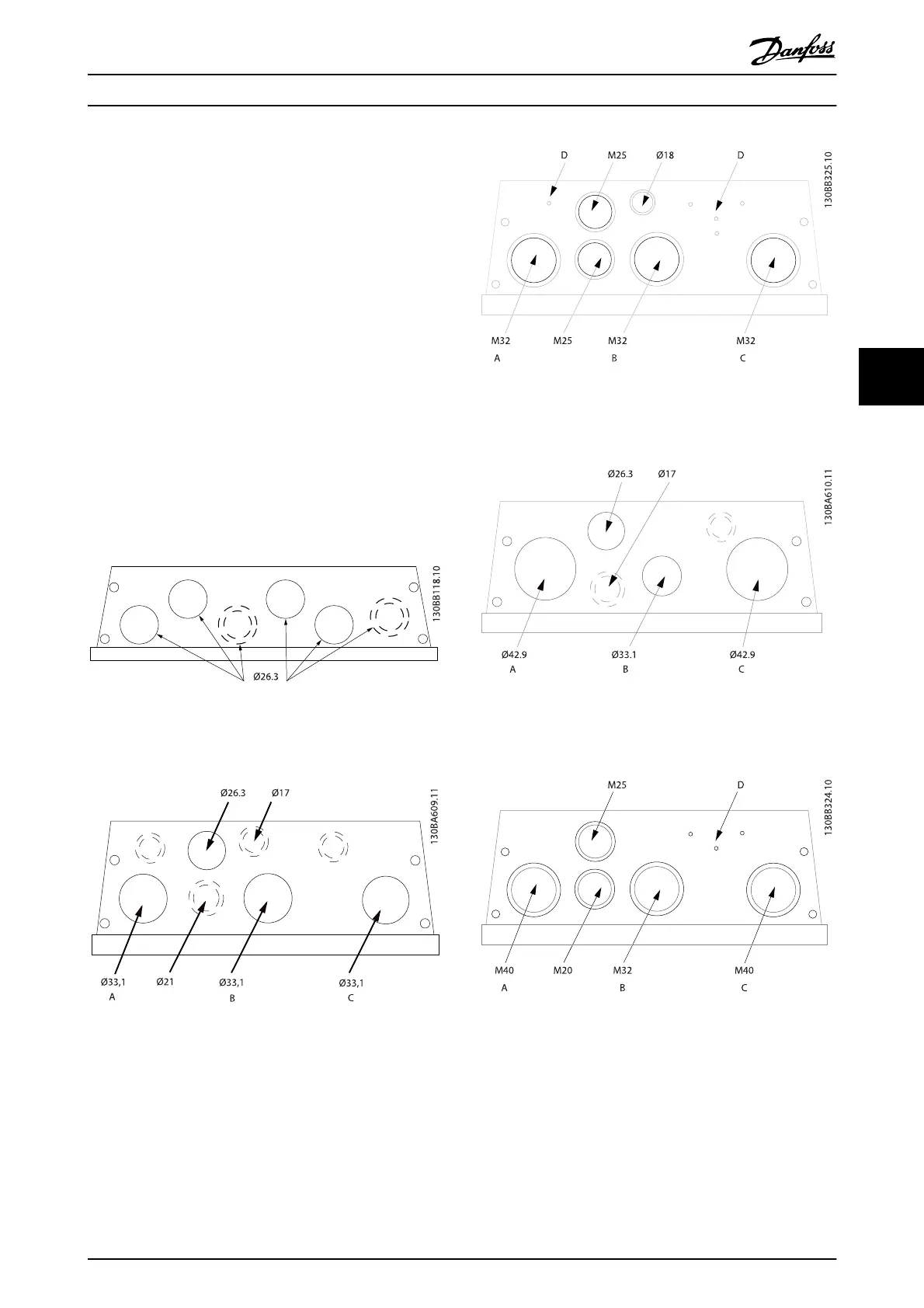

Illustration 5.9 Cable entry holes for enclosure B1. The suggested

use of the holes are purely recommendations and other

solutions are possible.

Illustration 5.10 Cable entry holes for enclosure B2. The

suggested use of the holes are purely recommendations and

other solutions are possible.

Illustration 5.11 Cable entry holes for enclosure B2. The

suggested use of the holes are purely recommendations and

other solutions are possible.

How to Install

VLT

®

Refrigeration Drive Design Guide

MG16G102 - VLT

®

is a registered Danfoss trademark 65

5

Loading...

Loading...