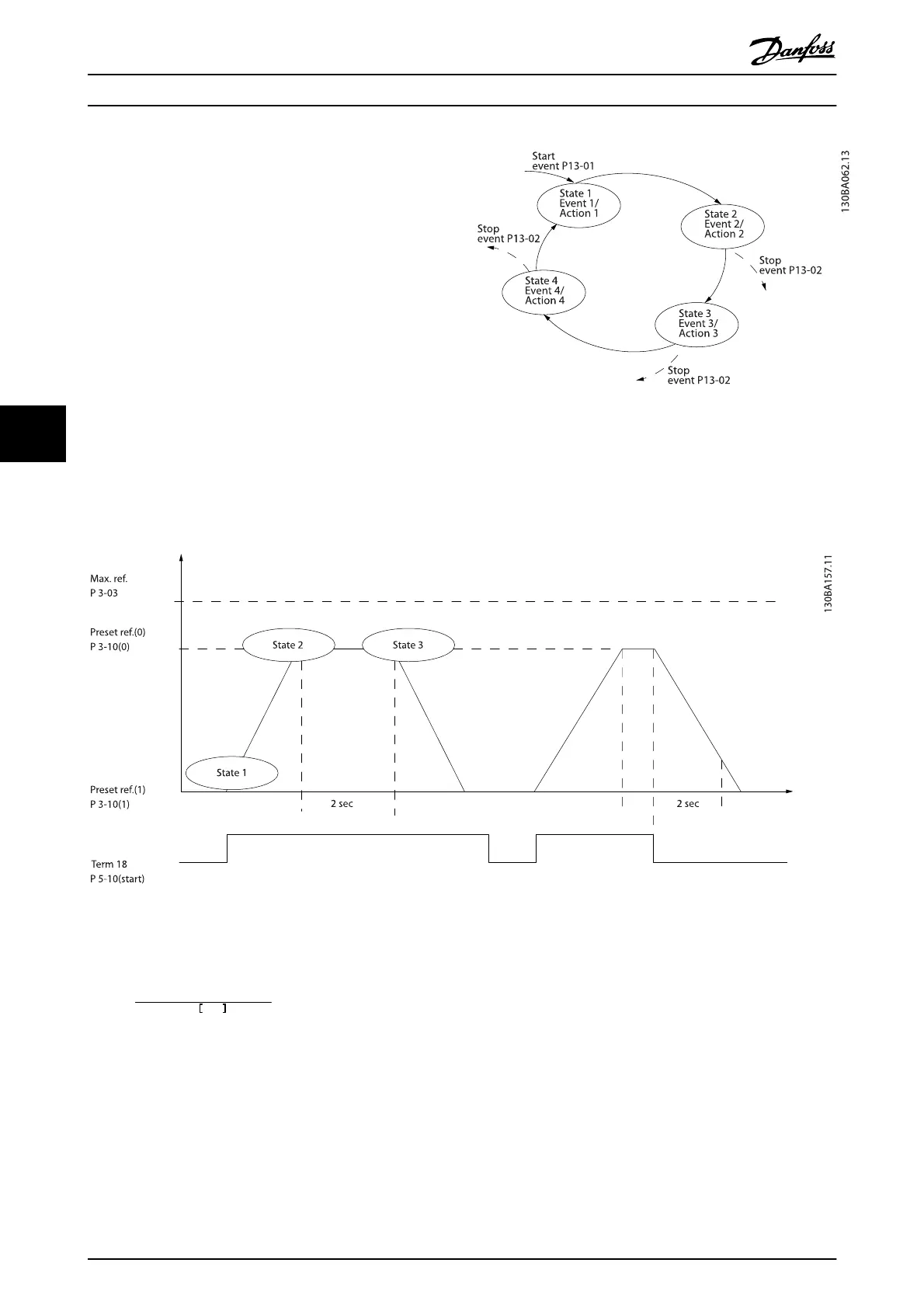

sequence starts over again from event [1] / action [1]. The

illustration shows an example with three events / actions:

Illustration 6.4

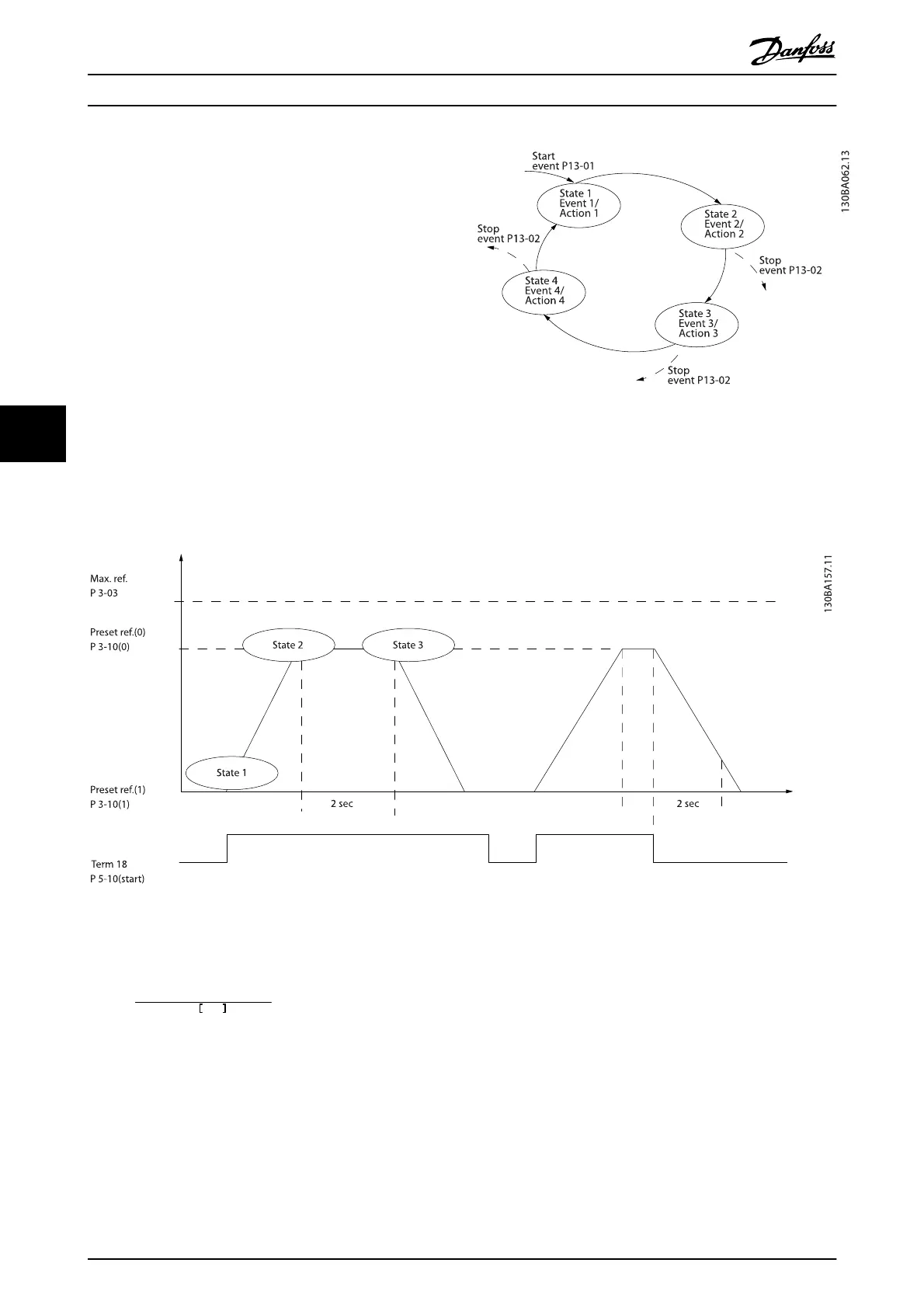

6.1.7 SLC Application Example

One sequence 1 Start – ramp up – run at reference speed 2 sec – ramp

down and hold shaft until stop.

Illustration 6.5

Set the ramping times in 3-41 Ramp 1 Ramp Up Time and

3-42 Ramp 1 Ramp Down Time to the wanted times

t

ramp

=

t

acc

×

n

norm

(

par

. 1 − 25

)

ref

RPM

Set term 27 to No Operation (5-12 Terminal 27 Digital Input)

Set Preset reference 0 to first preset speed (3-10 Preset

Reference [0]) in percentage of Max reference speed

(3-03 Maximum Reference). Ex.: 60%

Set preset reference 1 to second preset speed (3-10 Preset

Reference [1] Ex.: 0 % (zero).

Set the timer 0 for constant running speed in 13-20 SL

Controller Timer [0]. Ex.: 2 sec.

Set Event 1 in 13-51 SL Controller Event [1] to True [1]

Set Event 2 in 13-51 SL Controller Event [2] to On Reference

[4]

Set Event 3 in 13-51 SL Controller Event [3] to Time Out 0

[30]

Set Event 4 in 13-51 SL Controller Event [4] to False [0]

Set Action 1 in 13-52 SL Controller Action [1] to Select preset

0 [10]

Set Action 2 in 13-52 SL Controller Action [2] to Start Timer

0 [29]

Set Action 3 in 13-52 SL Controller Action [3] to Select preset

1 [11]

Application Examples

VLT

®

Refrigeration Drive Design Guide

84 MG16G102 - VLT

®

is a registered Danfoss trademark

6

Loading...

Loading...