1. Use a clamp from the accessory bag to connect

the screen to the frequency converter decoupling

plate for control cables.

See section entitled 5.7.3 Earthing of Screened/Armoured

Control Cables for the correct termination of control cables.

Illustration 5.24

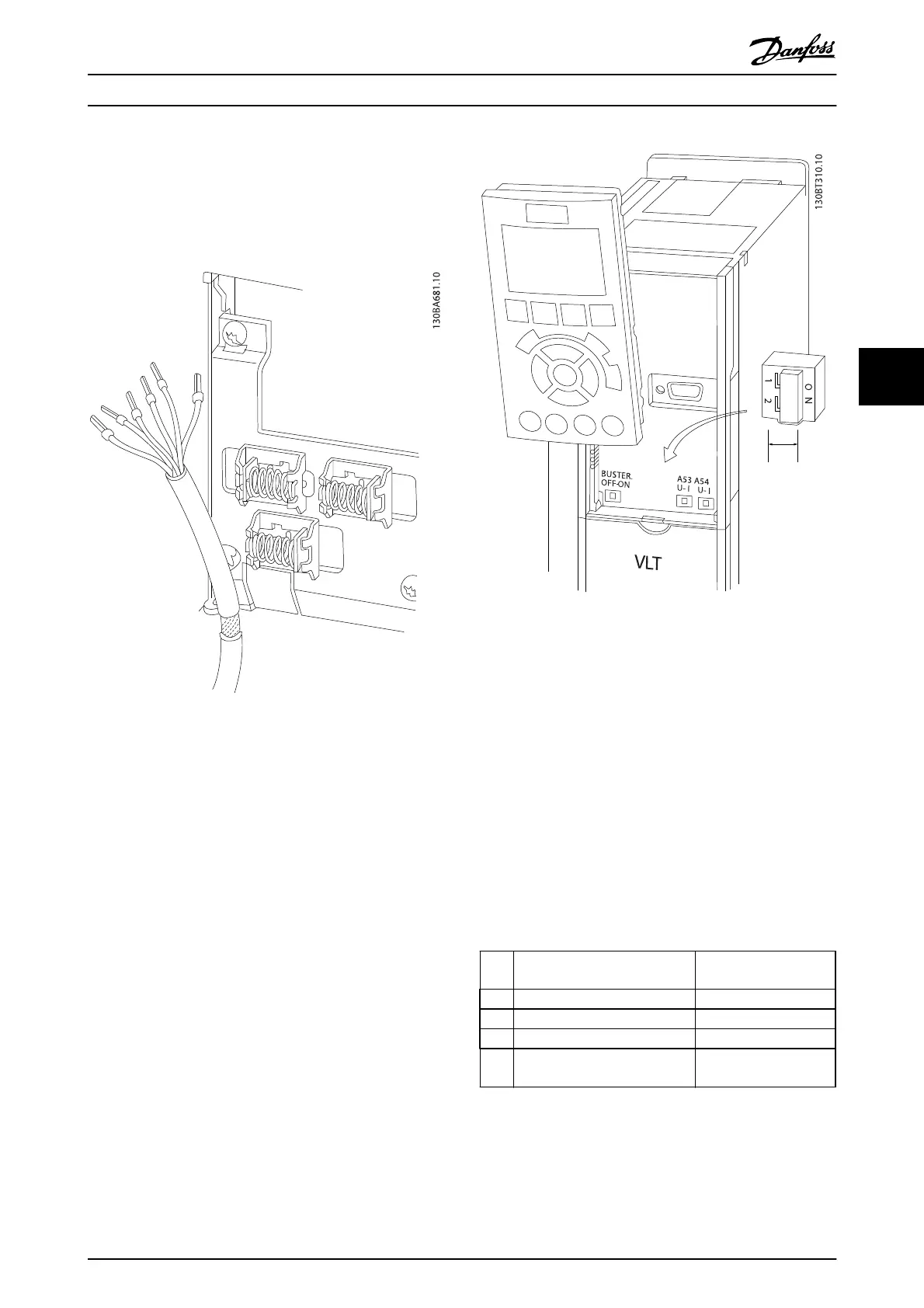

5.2.13 Switches S201, S202, and S801

Switches S201 (A53) and S202 (A54) are used to select a

current (0-20 mA) or a voltage (0 to 10 V) configuration of

the analog input terminals 53 and 54 respectively.

Switch S801 (BUS TER.) can be used to enable termination

on the RS-485 port (terminals 68 and 69).

See Illustration 5.23

Default setting:

S201 (A53) = OFF (voltage input)

S202 (A54) = OFF (voltage input)

S801 (Bus termination) = OFF

NOTE

It is recommended to only change switch position at

power off.

Illustration 5.25

5.3 Final Set-Up and Test

To test the set-up and ensure that the frequency converter

is running, follow these steps.

Step 1. Locate the motor name plate

The motor is either star- (Y) or delta- connected (Δ). This

information is located on the motor name plate data.

Step 2. Enter the motor name plate data in this parameter

list.

To access this list first press the [Quick Menu] key then

select “Q2 Quick Setup”.

1. Motor Power [kW]

or Motor Power [HP]

1-20 Motor Power [kW]

1-21 Motor Power [HP]

2. Motor Voltage 1-22 Motor Voltage

3. Motor Frequency 1-23 Motor Frequency

4. Motor Current 1-24 Motor Current

5. Motor Nominal Speed 1-25 Motor Nominal

Speed

Table 5.10

Step 3. Activate the Automatic Motor Adaptation (AMA)

Performing an AMA will ensure optimum performance. The

AMA measures the values from the motor model

equivalent diagram.

How to Install

VLT

®

Refrigeration Drive Design Guide

MG16G102 - VLT

®

is a registered Danfoss trademark 71

5

Loading...

Loading...