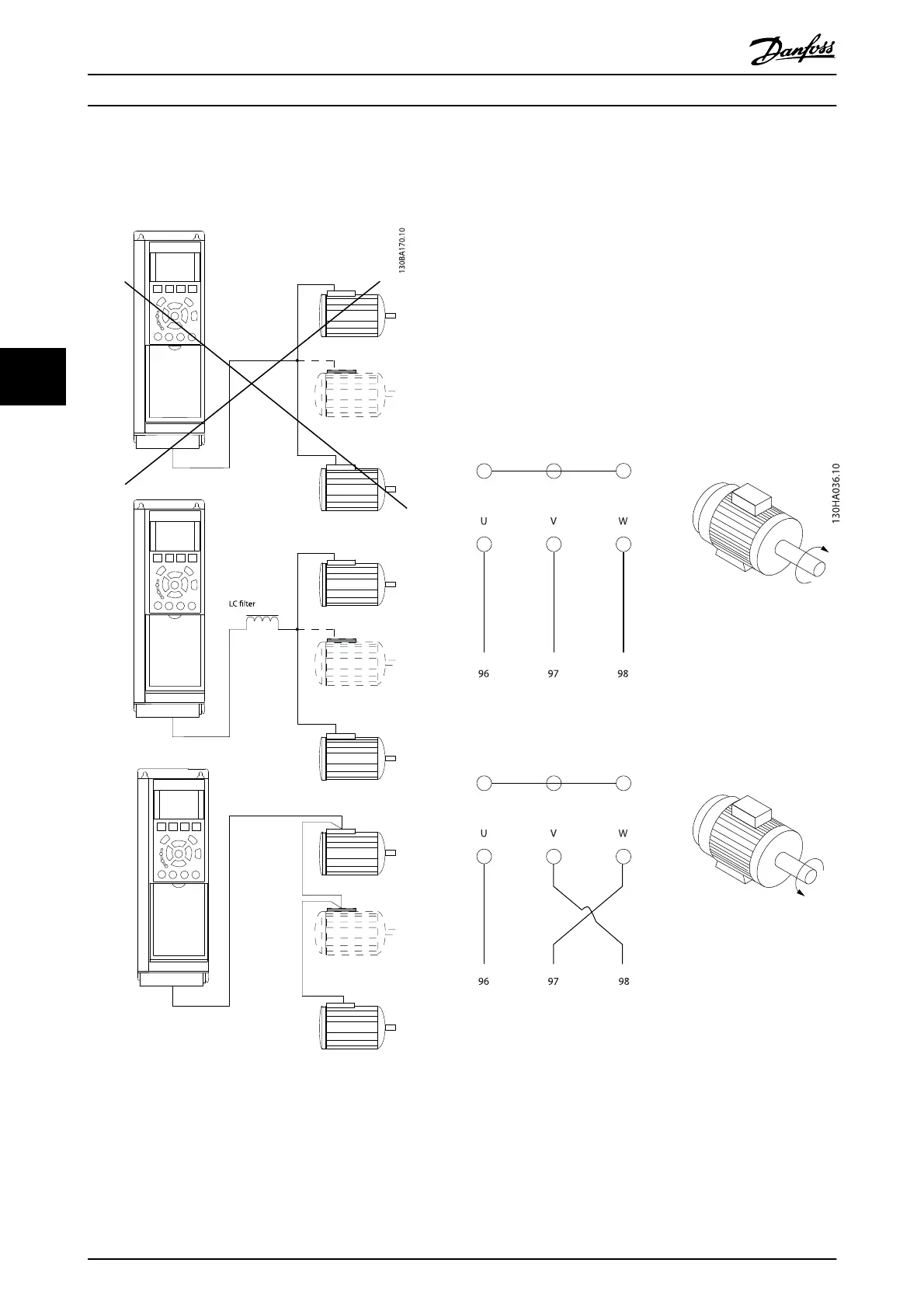

motors. Provide further motor protection by e.g.

thermistors in each motor or individual thermal relays.

(Circuit breakers are not suitable as protection).

Illustration 5.27

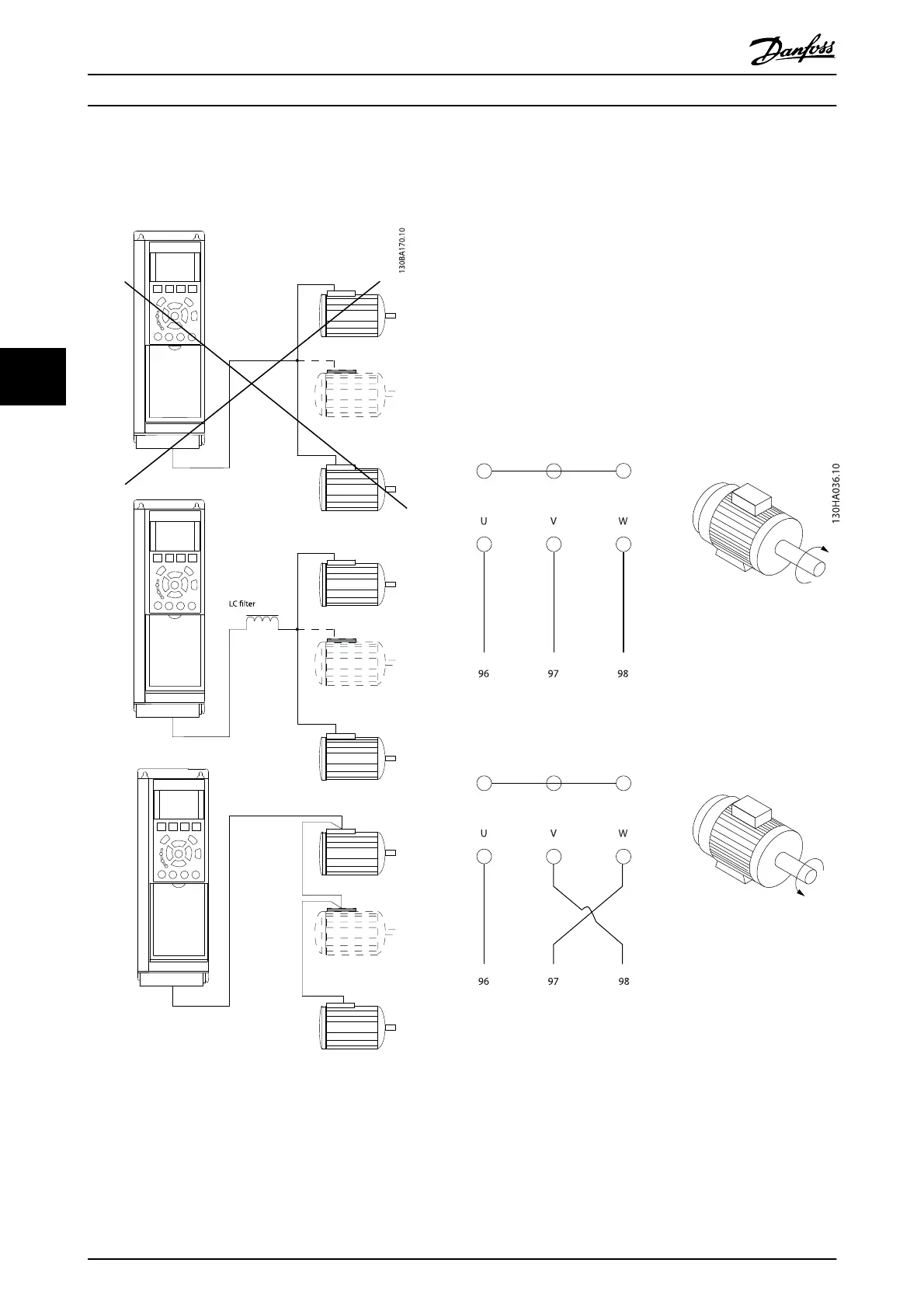

5.4.5 Direction of Motor Rotation

The default setting is clockwise rotation with the frequency

converter output connected as follows.

Terminal 96 connected to U-phase

Terminal 97 connected to V-phase

Terminal 98 connected to W-phase

The direction of motor rotation is changed by switching

two motor phases.

Motor rotation check can be performed using 1-28 Motor

Rotation Check and following the steps shown in the

display.

Illustration 5.28

5.4.6 Motor Thermal Protection

The electronic thermal relay in the frequency converter has

received the UL-approval for single motor protection,

when 1-90 Motor Thermal Protection is set for ETR Trip and

1-24 Motor Current is set to the rated motor current (see

motor name plate).

How to Install

VLT

®

Refrigeration Drive Design Guide

74 MG16G102 - VLT

®

is a registered Danfoss trademark

5

Loading...

Loading...