VLT

®

2800 Series

Programming

Lowpass filter

If there is a lot of noise in the feedback signal, these

can be dampened using an integrated lowpass filter.

A suitable l owpass filter t ime constant is preset.

If the lowpass filter is preset to 0.1 s, the cut-off

frequency will be 10 RAD/sec, corresponding to (10 / 2

x π) = 1.6 Hz. Th is will mean that all currents/voltages

that vary by more than 1.6 oscillations per second

will be dampened. In other words, there will only

be regulation on the basis of a fe edback signal

that varies by a frequency of less than 1.6 Hz.

The appropriate time constant is selected in Speed

Regulation in parameter 421 Speed PID lowpass

filter time and in Proces s Regulation in parameter

444 Process PID lowpass filter time.

I

nverse reg ulation

Normal regulati on means that the motor speed is

increased when the reference/setpoint is greater

than the feedback signal. If it is necessary to run

inverse regulation, in which the speed is reduced

when the reference/setpoint is greater than the

feedback signal, parameter 437 PID normal/inverted

control must be programmed at Inverted .

A

nti Windup

In the factory the process regulator is preset with

an act ive anti windup function. This function means

that when either a frequency limit, a current limit or

a voltage limit is rea ched, the integrator is initialised

at a frequency corres ponding to the present output

frequency. This is a m eans o f avoiding the integration

of a variance between the reference and the process’s

actual mode that cannot be deregulated by means of

a change of speed. This function can be deselected

in parameter 438 Process PID anti windup.

S

tarting conditions

In some applications the optimal setting of the

process regulator will mean that a relatively long

period of time will pass befo re the required process

condition is achieved. In these applications it can

be a good idea to define an output frequency to

which the frequency converter must run the motor

before the process regulator is activated. This is

done by programming a start frequency in parameter

439 Process PID start frequ ency.

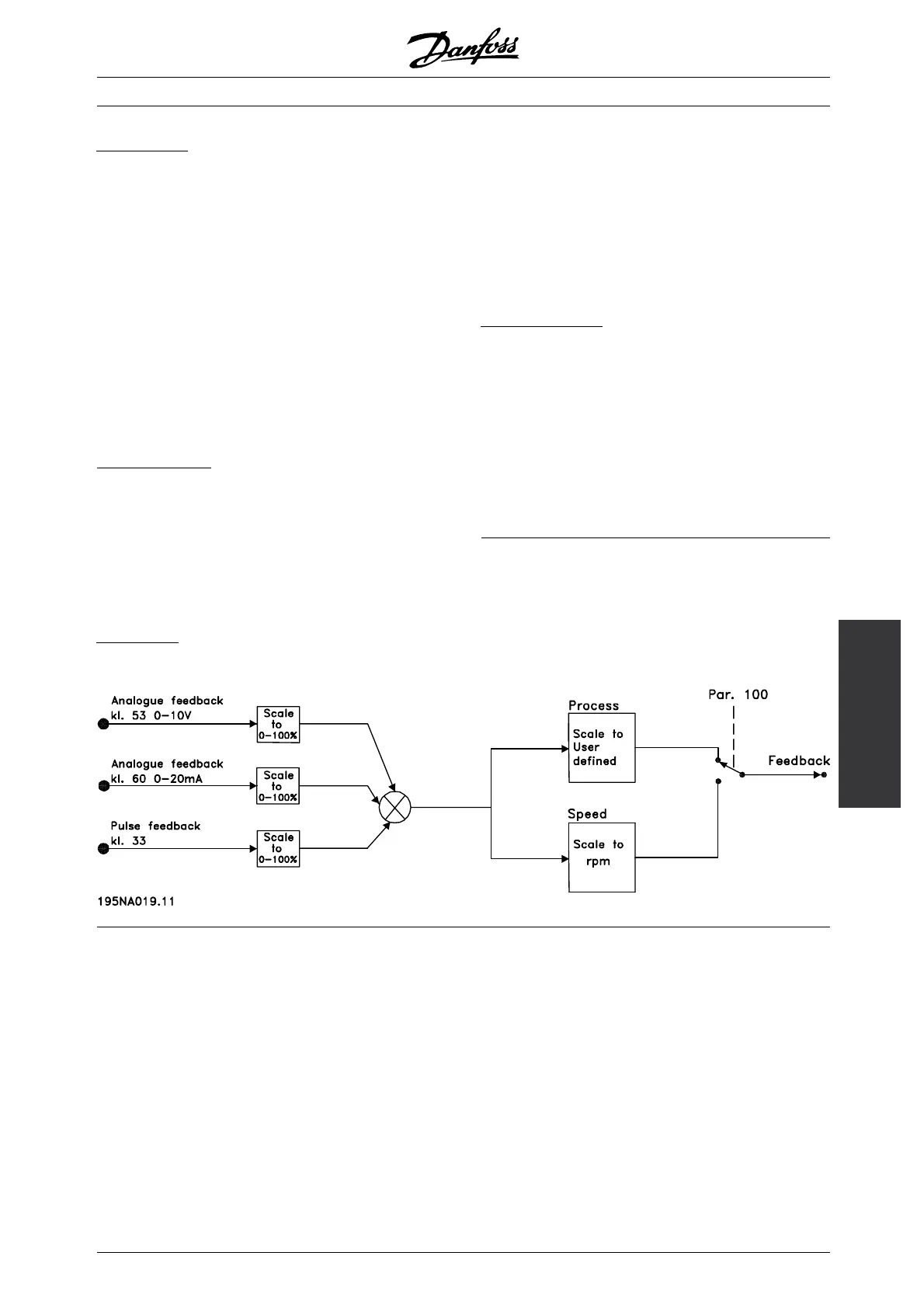

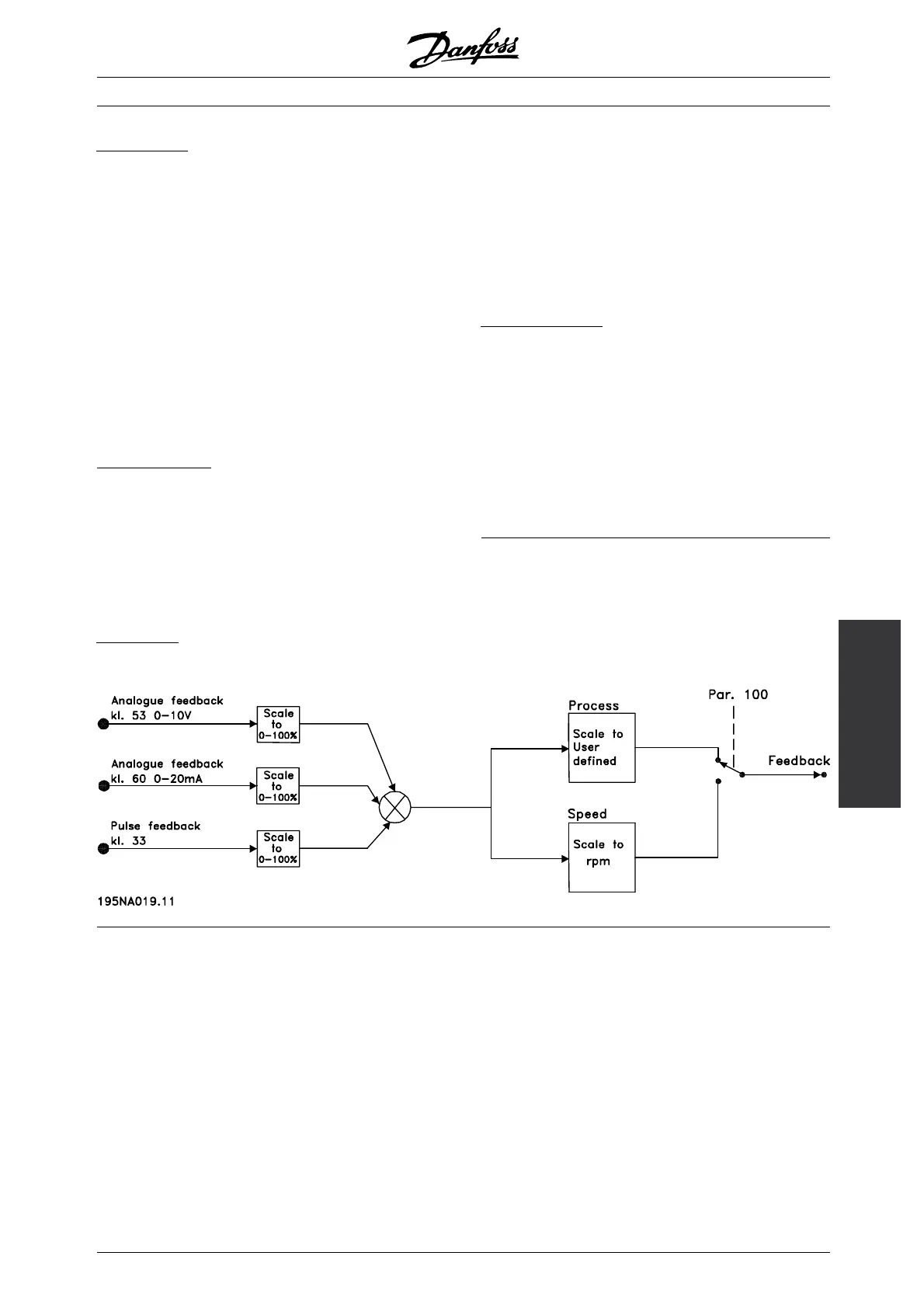

■ Handling of feedback

Feedback handling is depicted in this flowchart.

The flowchart shows which parameters can a ffect the

handling of feedback and how. A choice can be made

between voltage, current and pulse feedback signals.

✭ = factory setting. () = di splay text [] = value for use in communication via serial communicat ion port

MG.28.E9.02 - VLT is a registered Danfoss trademark

101

Loading...

Loading...