VLT

®

2800 Series

This table shows what the output frequency is:

Preset

ref., msb

Preset

ref., lsb

Selection

of Setup

Output

frequency[Hz]

0 0 0 2.5

0 1 0 5

1 0 0 10

1 1 0 17.5

0 0 1 20

0 1 1 25

1 0 1 35

1 1 1 50

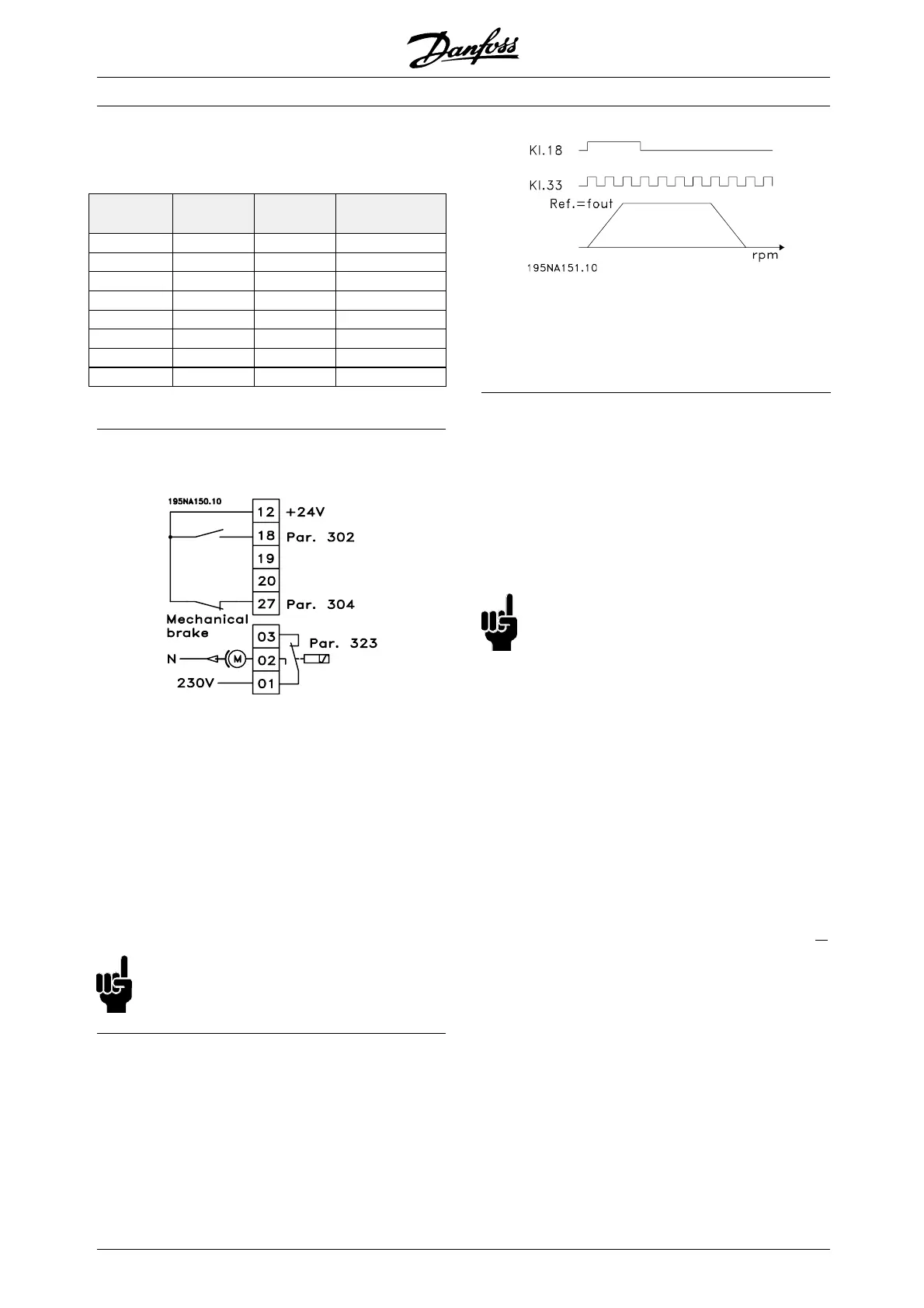

■ Connection of mechanical brake

Use of the relay for 230V AC brake

Par. 302 Digital input = Start [7]

Par. 304 Digital input = Coast ing stop inverted [2]

Par. 323 Re lay output = Mechanical

brake control [25]

Mechanical brake control [25] = ’0’ => Brake is closed.

Mechanical brake control [25] = ’1’ => The

brake is open.

See more detailed parameter settings under

Control of mechanical brake .

NB!:

Do not use the internal relay for DC brakes

or brake voltages > 250 V.

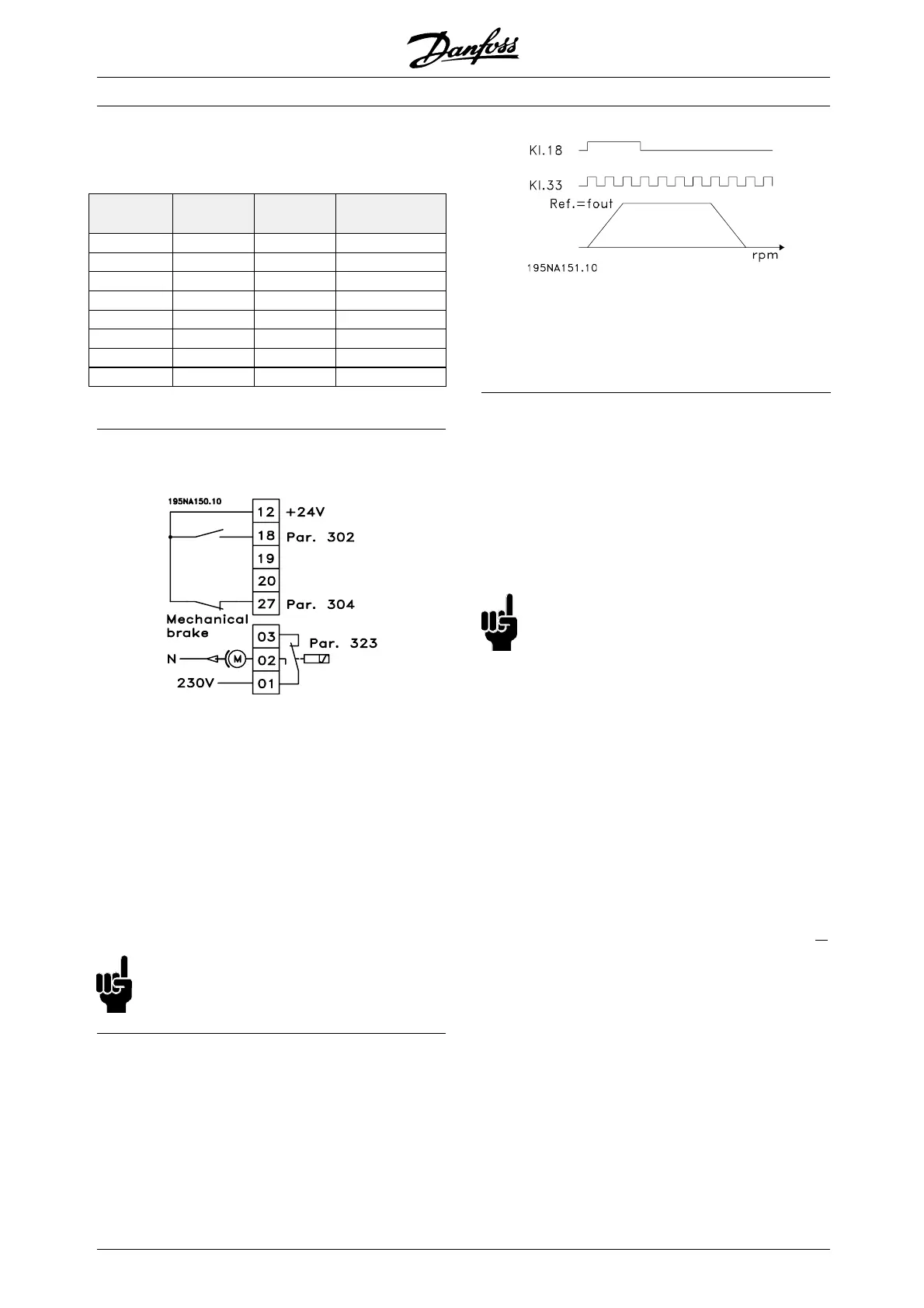

■ Counter stop via terminal 33

The start signal (terminal 18) must be active, i.e. logical

’1’, until the output frequency is equal to the reference.

The start signal (terminal 18 = logical ’0’) must then be

removed before the counter value in parameter 344

has managed to stop the VLT frequency converter.

Par. 307 Digital input = Pulse input [30]

Par. 343 Precise stop function = Counter

stop with reset [1]

Par. 344 Counter value = 100000

■ Use of internal PID-controller - closed

loop process control

1. Connect the frequency converter to mains

and motor cables as usual.

2. Connect transmitter (feedback signal) to + terminal

12 and - terminal 60 (applies to 2-wire transmitters

4-20 mA). (Connect transmitters with 0-10 V DC

to + terminal 53 and - terminal 55).

NB!:

Connect terminal 55 as - and terminal 60

as + for current signal (0/4-20 mA) and

terminal 53-55 for voltage signal (0-10 V DC) if

transmitters with separate voltage supply a re used.

3. Connect the start signal between terminal 1 2

and 18, 12-27 must be connected or set to

no function (parameter 304 = 0).

4. Set all parameters in the Quick M enu and enter

the Main Menu (to enter the Main Me nu: Press

Quick Menu and + simultaneously).

5. Set the following parameters:

100 = Proc ess controller closed loop [3]

101 = Variable torque medium [3]

If used with centrifugal pumps and fans.

308 = Feedback [2] (for 0-10 V DC transmitters) o

r

314 = Fe edback [2] (for 4-20 mA transmitters)

414 = Minimum feedback scaling, must be set

to the minimum feedb ack value

415 = Ma ximum feedba ck scaling, must be set

to the maximum feedback value

Example: Pressure transmitter 0-10 bar:

414 = 0 and 415 = 10

416 = Proce ss units: As shown on the local

control panel (example: bar [4])

437 = Normal [0]: The output frequency should be

reduced when the feedback signal increases

Inverse [1]: The output frequency should increase

when the feedback signal increases

440 = Proport ional gain (P-gain) 0.3-1.0

(experienced value)

MG.28.E9.02 - VLT is a registered Danfoss trademark

58

Loading...

Loading...