Operating conditions

Application envelopes

Short cycle control is directly provided by the

CDS303 frequency converter, when parameter

28.0x is enabled.

The function is factory set to enabled, with

minimum running time 12 seconds and interval

between starts 300 seconds.

Short cycle settings are accessible in parameter

28.0x list, in the “compressor functions” menu.

When fully controlled from an external main

controller it is recommended to limit to 12 the

number of start / stop per hour.

Please note to ensure compressor is well

lubricated, it is required to keep VZH compressor

running at least 3 minutes each time after start.

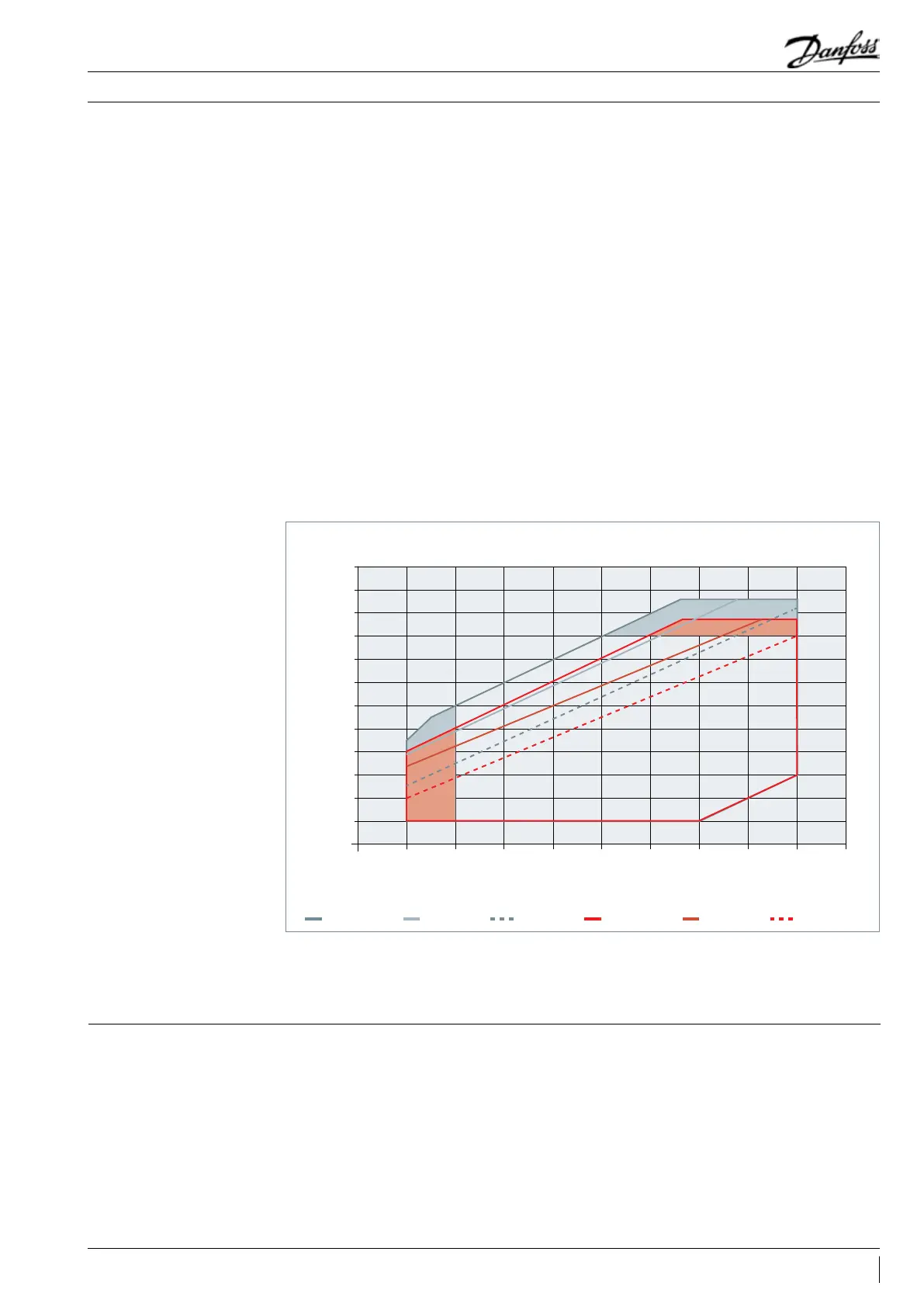

Note: Red and Gray lled area are limited to 30-90rps.

for 380V power input, permitted highest condensing temperature will decrease accordingly:

-High PR: 25-100rps, condensing temperature from 60C to 56C; 30-90rps, condensing temperature from 68C to 65C

-Low PR: 25-100 rps, condensing temperature from 60C to 56C; 30-90 rps, condensing temperature from 63C to 62C.

Short cycle timer function

The operating envelopes for VZH scroll

compressors are given in the gures below,

where the condensing and evaporating

temperatures represent the range for steady

state operation. Under transient conditions, such

as start-up and defrost, the compressor may

operate outside this envelope for short periods.

The gures below show the operating envelopes

for VZH compressors with refrigerants R410A.

Due to bearing loads and scroll stability,there

will be speed restrictions on the envelops. The

operating limits serve to dene the envelope

within which reliable operations of the

compressor are guaranteed:

• Maximum discharge gas temperature: +135°C.

• In any condition the expansion device must

ensure a suction super heat within 5k to 30k.

• To avoid liquid oodback, oil sump superheat

should also be taken care of. Please refer to

“liquid oodback during operation” section.

• Attention to suction line insulation to reduce

usefulness superheat.

• Minimum and maximum evaporating and

condensing temperatures as per the operating

envelopes.

• VZH drive could only protect compressor from

over current. Customers need to have high

pressure, low pressure sensor and discharge

temperature thermostat to fully protect the

envelop. Since out of map running will threaten

the reliability of compressor, customers must

qualify map protection under all extreme

conditions.

15

25

30

20

35

40

45

50

55

60

70

65

75

Condensing temperature (°C)

VZH operating map - 575V/400V/208V

-30 -20 -15-25 -10 -5 0 5 10 15 20

Evaporating temperature (°C)

25-100rps

High PR (6-10K) High PR (15K) High PR (30K) Low PR (6-10K) Low PR (15K) Low PR (30K)

30-90rps

30-90rps

41FRCC.PC.023.A8.02

Application Guidelines

Loading...

Loading...